Common fluids valves explained: Pressure reducing valve - pressure reducing valve symbol

Boiler feed water regulatordiagram

To eliminate this erosion problem in the application, the IMI CCI team offered the proven DRAG® technology trim design. This trim design has 12 pressure reducing stages to eliminate cavitation and limit trim exit velocity to less than 23m/s (75 ft/s) in the IMI CCI design valve. In addition, a removable seat basket was designed to go inside the valve body preventing any body erosion in the event of unforeseen flashing conditions. The team presented the solution in detail to the customer with references to thousands of successful installations around the world. The customer has placed an order to replace all eight competitor boiler feedwater regulator valves at this plant.

Boiler feedvalve with Backflow Preventer

This is the second unit I’ve installed as the first one, installed two winters ago in another building is working so well. No problems, easy to install. Both systems are hydronic floor heat and these units work great. Just fyi…….going to electric now works out cheaper than the original propane costs. Like that it’s Canadian made.

Enhance sustainability, efficiency, and productivity in industrial plants by reviewing existing valve care controller capabilities.

Boiler feed watercontrol system

Detailed information was collected and an analysis was performed which led to the discovery that the existing valves were not suited to handle the actual operating conditions. The existing trim with drilled hole cage design generated 140m/s (459 ft/s) trim exit velocity at pressure drops of 140barg against ISA recommended trim exit velocity guidelines of 23 m/s (75 ft/s). The high trim exit velocity combined with cavitation is the main reason for the cage and body erosion.

IMI Process Automation is IMI's core sector for the design, manufacture and installation of highly engineered critical flow control systems for severe service and other challenging environments.

Bestboiler feed water regulator

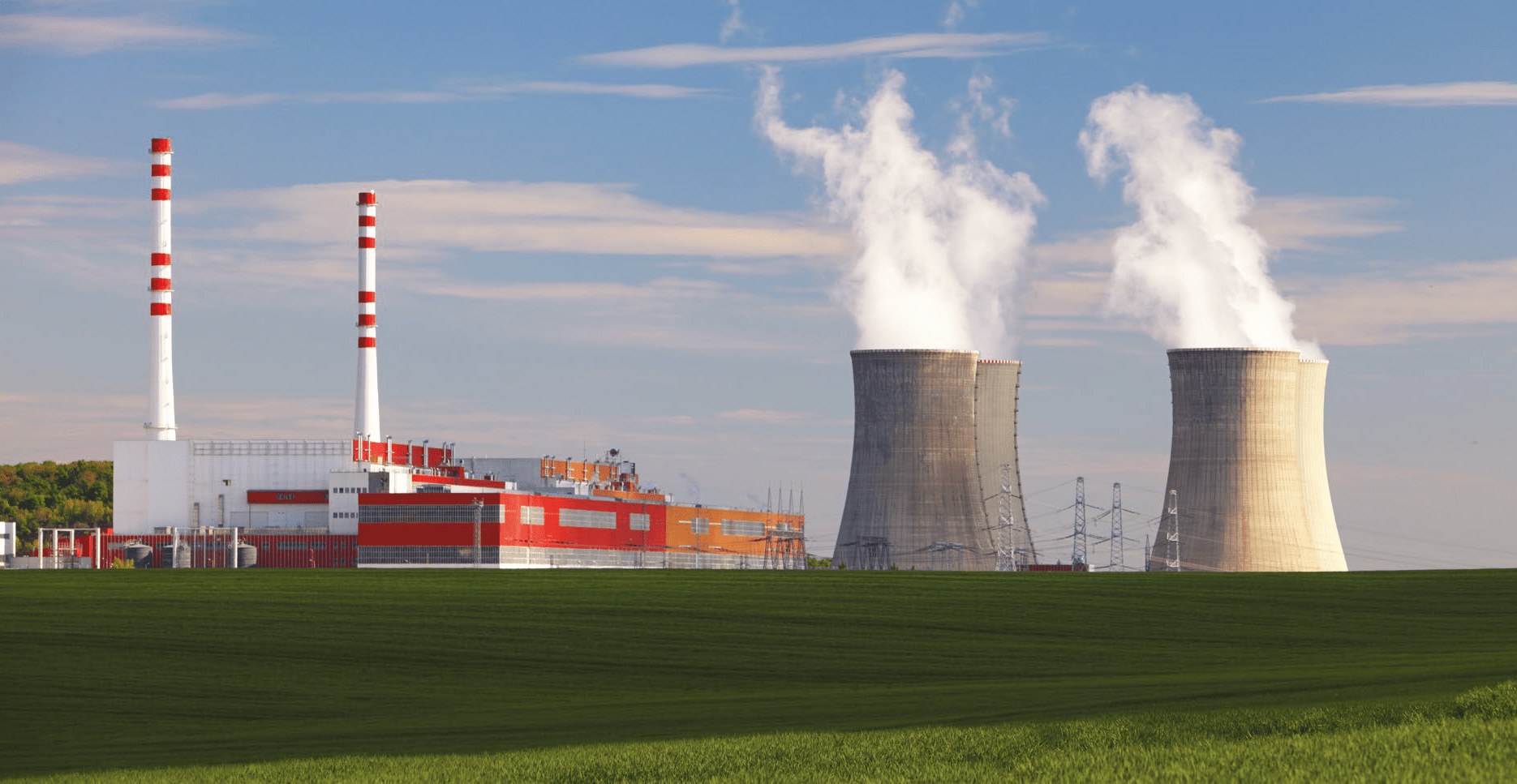

A petrochemical complex in Saudi Arabia with a cracker unit that produces one million tons of ethylene per year was experiencing frequent body and trim erosion from a competitors’ boiler feedwater control valve. After repeated attempts, the competitor was unable to fix the issues. The IMI CCI upgrades team was on site when the existing competitor’s three inch, ANSI 1500 class main feedwater control valve was brought in for maintenance and witnessed the pin-hole erosion damage at the valve outlet. During discussions with the customer, the team understood that repeated maintenance of the trim and body resulted in the customer needing to periodically perform welding repairs to the body.

Enhance sustainability, efficiency, and productivity in industrial plants by reviewing existing valve care controller capabilities.

I bought these to replace some wax actuators from my old system. Those were inconsistent (each moved a different amount) and had huge in rush power requirements. These have low power requirements and appear to be very consistent.

Boiler feed water regulatorreplacement

I purchased this glycol pump as part of the build your own, which included the manifolds pump, expansion tank, air separator and basic plumbing supplies. I was very happy with how everything arrived together and the install was straightforward just from looking at the pictures. The glycol pump makes it easy to charge the system, and took a lot of the guesswork out of setting it up. My garage now has toasty warm floors.

8615510865705

8615510865705

8615510865705

8615510865705