CPS PT200W Wireless Digital Pressure and Temperature ... - pressure temperature gauge

Voltacast 3200 is suitable for embedding and potting of transformers (in particular small transformers) and electronics. Voltacast 3200 contains non-abrasive fillers. Therefore it is especially suitable for sensitive mixing and dispensing equipment. To achieve customized properties additional non-abrasive fillers may be added to the product on customers’ behalf.

Before calling WIN, you can test the T&P Valve lever to release a bit of water. If water doesn't come out, or if it seems to leak or drip constantly, you have a problem. This isn't just about industry compliance; it's about peace of mind, knowing your home is safe from potential water heater mishaps. T&P valves are connected to a small metal arm or tab that assists with opening. The resolution to a broken valve is to replace it entirely with the help of a licensed and qualified plumber.

Your T&P Valve is a silent guardian, but even guardians need annual check-ups. We suggest testing your T&P valves annually through our Healthy Home Check, a recurring and comprehensive home inspection without the hassle and excess time required for a Full Home Inspection and report. Even if you had your T&P Valve properly checked when you bought your home, elements like this can break and deteriorate as time progresses. T&P valve testing is essential to ensure minerals and other particles don’t clog the valve’s interior or block it from proper operation.

Building 2, Jinwen Rd. 106 · Pudong New District · CN-201323 Shanghai Phone: +86-21-518-771-82 ext. 808 · Fax: +86-21-33-770-355 info@synflex.org.cn

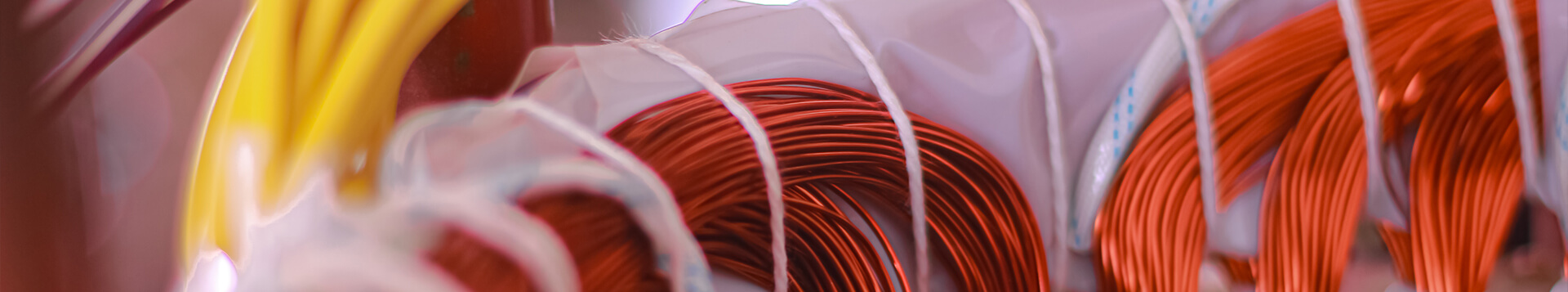

The core competence of SynFlex lies in the development, manufacturing and distribution of conducting and insulating products for the electrical insulation systems of electrical motors, transformers and generators.

Let's break it down. The T&P Valve is a tiny device sitting atop or just a bit below the top of a water heater. It constantly measures the heat and pressure inside your device. Think of it like a safety valve that steps in when components get too hot or too pressurized. When they do, the valve opens and lets out water to bring the system back to equilibrium. A typical T&P valve opens at a pressure of 150 psi and a temperature of 210 degrees Fahrenheit. Without a T&P Valve, your water heater could seriously injure you or your family through water damage or, in the worst case, bursting.

Sometimes, the T&P valve opens more often when the water heater lacks a thermal expansion tank. A thorough and professional examination of your water heater will give you the necessary knowledge to understand your T&P valve’s operation. Regardless of your water heater’s structure, plumbing standards require a T&P valve and proper discharge pipe, which safely channels any released hot water away from the heater, across all water heaters.

The cured resin compound is biologically inactive and not dangerous to health. When processing the liquid components please refer to the respective Material Safety Data Sheets (MSDS’s).

Due to the contents of fillers which will settle to the ground during a longer storage period Voltacast 3200 needs to be stirred up homogenously (without including foam) prior to use. In any case the resin shall rest for about 2 hours after stirring to allow degasing. The time needed for degasing the resin may be shortened by storing the resin at approx. 60 °C or at a vacuum of approx. 20 mbar. Provided the mixture is consumed very soon, the hardener Voltacast H132 may be added to the warm resin. Otherwise the resin has to cool down to room temperature again in order to avoid a significant shortening of the mixture’s pot life. Casting resin, hardener and mixtures made must be protected against humidity! The temperature in the working area must be above 18 °C! The same way it is essential to dry the parts the casting resin shall be applied on. An example for best practice is to extract all humidity on and inside the parts used by drying them at approx. 50 °C for about 1 hour, as otherwise the resin may form gas bubbles while curing. Hardener Voltacast H132 shall be added to the casting resin in the mixing ratio stated above. The mixture has to be stirred homogenously and carefully without including foam. Provided the product shall be blended with extra fillers, these fillers must be completely dried prior to adding them to the casting resin. Best practice to add fillers to the product is to add the respective amount slowly and to stir the product until a homogenous mixture is ensured. The same way it is useful to heat up the mixture moderately to 60 °C or to establish vacuum in order to accelerate the degasing as mentioned above. Voltacast 3200 can be applied on all common mixing and dispensing equipment with or without applying vacuum.

After curing for 48 hours at 20 °C minimum the resin compound can be fully stressed (both mechanically and electro-technically).

In closed original cans and at 25 °C storage temperature maximum the resin can be stored for 12 months. The hardener can be stored for 6 months under the same conditions. Both resin and hardener have to be protected against water and humidity and therefore must not be stored outside. Additionally the respective hardener must be stored and transported frost-protected (above 10 °C).

A former home inspector, Pat serves as the Director of Training and Licensing for WIN Home Inspection, Pat has been in the inspection services industry for over 30 years and is an expert in performing and teaching 35+ essential services.

Once cured the resin compound is almost insoluble. Therefore, application equipment should be cleaned regularly with cleaner Voltatex® T050. All equipment cleaning and maintenance should be carried out in accordance with the equipment manufacturer’s instructions.

When we inspect homes, we pay special attention to the T&P Valve. We don't test them ourselves, but we do look to see if they exist and are in good condition. We also check the discharge pipes to ensure correct material, quality and installation. These might seem like small details, but they're big indicators of your water heater's health and safety. Ensuring these components are in order leaves you with peace-of-mind and cost savings in the long run. Remember, a little attention to the T&P Valve can go a long way in keeping your home safe.

Upon installation, the water heater’s T&P Valve should be properly positioned and functional. The device should be mounted either at the top or the side of your water heater apparatus and be within a 6” clearance on top. The water discharge pipe should also be safely installed and maintained. The pipe must be made of the right materials to prevent melting. PVC, for instance, is not suitable for hot water and could fail at a crucial moment as it is only cold water-rated. The only exception stands when a pipe PVC reads that it is approved for T&P valve discharge use, as denoted by a red print in most cases. Other plumbing materials, like copper, PEX, CVPC, and polybutylene (PB) can be used instead. Two of the most common issues identified during a home inspection are an incorrectly installed discharge pipe and a T&P discharge pipe that is not hot water rated. Improper discharge pipe installation, make-up or lack thereof can lead to 2nd-to-3rd degree burns from scalding. During our inspections, we always take a close look at these valves and pipes because proper installation ensures safety. A correctly installed T&P Valve is like having a good insurance policy – you hope you never need it, but it ensures maximum coverage and reduced costs when you do.

Upon installation, know the T&P discharge pipe must be the same size, not smaller, as the T&P valve to prevent flow constriction and further pressure build-up. Without a discharge pipe, the T&P valve could shoot out scalding water, seriously injuring anyone nearby.

Normally, a T&P valve should not drip. Small amounts of drip below the valve are typically no cause for concern, but we advise carefully monitoring the situation. Larger puddles and splashes are indications of serious inspection and repair. Typically, the solution here is to replace the T&P valve or thermal expansion tank or install a pressure regulator – depending on the structural integrity of your water heater apparatus. To ensure your health and safety along with your water heater longevity, leave the inspection and replacement process to qualified professionals only.

During the winter months, when home fires grow in frequency, heating safety is of the utmost importance. One part of your water heater plays a large role in operational safety: the Temperature and Pressure (T&P) Relief Valve.

You have questions according to our resins and varnishes or want to send an inquiry? Our sales representative will be happy to help you.

Ekşioğlu Mahallesi 38. Sokak No:4, TR-34794 Çekmeköy/İstanbul Phone: +90-216-415-97-97 · Fax: +90-216-415-97-55 info@synflex.com.tr

Voltacast 3200 is a pigmented, filled and cold-curing two-component polyurethane casting resin with low temperature development while curing, based on hydroxy-functional polyester. The product is available in black or white colour. The hardener Voltacast H132 is based on aromatic polyisocynate. The product is available in white and black colour.

8615510865705

8615510865705

8615510865705

8615510865705