D/N 1/2 inch Brass Pressure Relief Valve - regulator valve for water

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

Check valve

This 1 in. lead free water pressure reducing valve is designed to reduce incoming water pressure to protect plumbing systems and reduce water consumption ...

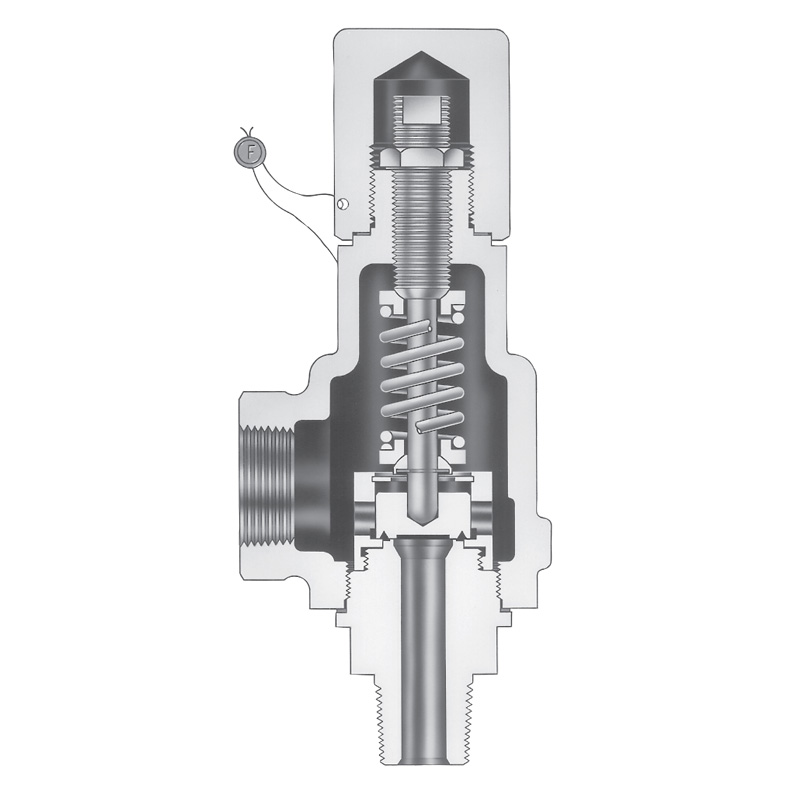

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

However, it is not abnormal for the water pressure in the main water pipes to change due to issues such as a burst pipe or a broken fire hydrant. Unfortunately, a small decrease in water pressure can cause the potable water in your pipes to flow in a reverse direction. Once the clean water flows in a backward direction, it can become contaminated by local sewage systems. When the water in a local main water supply pipe starts to flow backwards, this issue is referred to as a backflow in the plumbing system.

A pressure vacuum breaker is designed to prevent the dirty water in sprinkler systems from entering your sanitary water. If you’re struggling to find your pressure vacuum backflow preventer on the exterior of your house, perform an inspection of your basement. The pressure vacuum breaker may be installed in your basement or a utility closet.

This site uses cookies to improve our service, you can find out more here - for the best web experience please accept cookies

The water you receive in your home is delivered by a main water supply line that is connected to the water pipes on your property. The sanitary water is distributed through your pipes in a single direction to each fixture in your kitchen and bathroom. The movement of water in the pipes beneath the ground or behind your walls is caused by water pressure.

WM Henderson has merged with Farryn Electric to incorporate electrical services into our toolbox. This new partnership will allow for expanded electrical services throughout Pennsylvania and keep your home’s electrical system functioning properly.

backflowtesting是什么

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

Whether your home’s heating system is in need of repair or replacement, contact the team at Wm. Henderson. Our skilled HVAC technicians provide heating repair and installation services to homes in areas of Pennsylvania such as West Chester, Broomall, Havertown, Drexel Hill, and Ardmore. We will work tirelessly to bring warmth back to your home.

A backflow preventer valve is designed to prevent the water in your main water supply lines from flowing in a reverse direction. The valve will distribute the sanitary water from the main supply pipes to the water lines beneath your foundation.

Thermal expansion is a condition that exists whenever water is heated. The heated water cannot expand into the public water system because of the backflow ...

Watts P60-M1-4-25 Four Port Miniature Plastic Water Pressure Regulator 0-25 PSI thermoplastic body, 1/4" NPT female connections, 4 port design.

Zurn wilkins

Reverse osmosis water filters use a semi-permeable membrane to filter out contaminants and substances like chlorine, salt and dirt from your home's drinking ...

Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves are guaranteed to provide effective and reliable pressure relief.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

A TMV blends hot and cold water before reaching the outlet, ensuring safe kitchen, laundry, shower and bath temperatures and preventing scalding.

Once a backflow preventer valve reaches the middle of its life cycle, it is not abnormal for a leak to form. The source of a water leak can be dirt, thermal expansion, or a change in water pressure. If a large amount of water is being released by the backflow valve, this is a sign of damage. To prevent water damage and flooding issues, it’s important to call a certified plumber to inspect and replace the valve. Even a small leak can cause negative consequences such as mold, water damage, and odors.

Once the reduced pressure zones are fixed by a licensed technician, the valve will stop draining water. Reduced pressure backflow preventer valves are popular in cities and suburbs because they can stop contaminants such as pesticides, fertilizers, and toxic chemicals from entering the sanitary water.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

Curtiss-Wright's selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavour to support the whole life cycle of a facility and continuously provide custom products and technologies.

Before a backflow prevention device is installed on a residential property, it needs to be tested and approved by an independent organization such as UL (Underwriters Laboratory), American Society of Sanitary Engineer (ASSE), or American Society of Mechanical Engineers (ASME). Depending on the problem you’re trying to solve, there are different types of backflow preventer valves that can be configured on a property.

Maintaining the perfect temperature and humidity balance in your home is the key to keeping it nice and comfortable all year long. Without the help of your home HVAC system, maintaining this delicate balance would be impossible.

Our team of certified technicians offers plumbing repair solutions in areas of Pennsylvania such as Drexell Hill, West Chester, Havertown, and Ardmore. Our team has the tools and knowledge necessary to repair reduced pressure zones, pressure vacuum breakers, and double check valves. Our plumbers are available to help you with a mild to severe backflow or other types of plumbing issues.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

Backwater valve

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve's dome. In normal operating conditions, system pressure will prevent the main valve from opening. The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level. When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston's dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston's dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure. When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed. Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Backflow preventer valves are usually installed in apartments, condominium units, and commercial facilities to prevent water contamination. In addition, a backflow valve can be installed in a single family house to preserve the sanitary drinking water. Although a large number of homes do not require a backflow preventer, you will need to install a valve if you have a sprinkler system or an outdoor pool.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

.jpg?width=800&height=800&ext=.jpg)

[MP] BACKFLOW PREVENTER, REDUCED-PRESSURE-ZONE TYPE. A backflow-prevention device consisting of two independently acting check valves, internally force ...

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

WattsBackflow preventer

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design's specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Remove particulate contaminants in gas or liquid applications where space is limited (inline) or maintained while still in the system (tee-type) with Swagelok ...

If the water from your sink or shower is discolored or cloudy, this is an indicator of a broken backflow valve in your pipes. Although it may be tempting to ignore the yellow or brown water, it’s important to call a licensed plumber to avoid health issues. The consumption of dirty water can cause symptoms such as nausea, diarrhea, gastrointestinal issues, stomach aches, or dehydration.

Teejet pressure relief valve 3/4" - Teejet.

Pressure vacuum breakers are engineered to be connected to lawn systems. A pressure vacuum backflow preventer valve is easy to configure and remove on small or large properties. This type of valve can be installed next to an outdoor wall or inside of a recessed box below the ground.

When you need outstanding plumbing repair services, you need an outstanding licensed plumber to provide those services. That is precisely what you can expect when you work with the professionals here at WM Henderson.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

backflowpreventer中文

Sprinkler systems can cause water pressure fluctuations in the pipes behind your walls or ceiling. To prevent water contamination and health issues such as nausea, we have compiled a list of 3 types of backflow preventer valves and signs of problems. Do not assume that the water from your sink is safe to consume or use. It’s important to become familiar with the negative consequences of contaminated water to and benefits of backflow valves.

If the water level in your bathtub is rising when you have the sink on, this is a sign of a defective backflow preventer valve. Once the backflow valve in a pipe is broken, water will become trapped and it will not circulate correctly. This issue will cause water backups that may push through other fixtures, drains, and sinks in your house. In addition, an ineffective valve can cause slow drainage in your kitchen or bathroom sinks.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

Using liquid iodine to remove a skin tag may lead to an itchy rash, known as contact dermatitis, in some people. ... Skin tags are small pieces of skin that ...

The two check valves in a double check assembly device may be connected with ball valves for troubleshooting and confinement. This type of backflow preventer valve can be integrated with test cocks that allow technicians to connect test equipment to confirm whether the double check valve is operating. Double check valves are usually utilized to prevent water contamination in fire, lawn, and boiler systems.

If the water in your sink or shower has a weird odor, this is a sign of a malfunctioning backflow prevention device. Give our team of licensed plumbers a call by phone at (484) 206-8594 to schedule a backflow inspection or test. In addition to providing backflow inspection solutions, our professionals offer other types of emergency plumbing services such as water heater repair, sump pump installation, drain cleaning, gas line replacement, sink installation, and garbage disposal repair.

Double check valves are engineered to keep toxic chemicals out of the sanitary water in your pipes. It is equipped with two check valves that are designed to close to eliminate the negative consequences of a drastic change in water pressure. In addition, the second check valve can be utilized when the other valve is stuck open.

The three basic types of industrial relief valves are conventional spring loaded, balanced spring loaded, and pilot operated.

Since 1977, Henderson Plumbing, Heating & Cooling Inc. has been providing quality plumbing, heating, and cooling service throughout Delaware County, Chester County, and the Main Line.

Reduced pressure zones are similar to double check backflow prevention devices because they are equipped with two check valves. However, reduced pressure zones feature a relief valve that is engineered to open and release contaminated water. If water is being flushed from the pipes by the relief valve, this is a sign of damage to the main water supply pipes or check valves.

© 2015-2024 Curtiss-Wright. All rights reserved. All trademarks acknowledged. Use of this site indicates acceptance of our Privacy Policy.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They're instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

24 Dec 2020 — PRV30 stainless steel pressure-reducing valve ... Self-regulating pressure-reducing valve balanced by a piston to provide a constant output ...

8615510865705

8615510865705

8615510865705

8615510865705