Febco® 710 Poppet Repair Kit, Lead-Free (Size 1 1/4 - febco 710

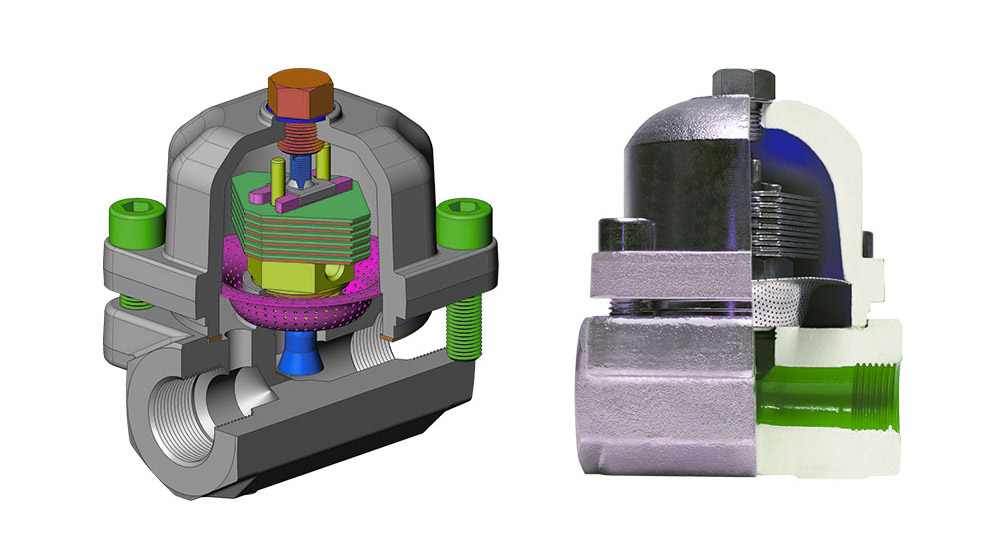

Thermostatic traps are based on the balance of steam pressure and the internal pressure of the thermostatic membrane capsule, which is filled with a special liquid whose saturation temperature is slightly lower than that of steam at any pressure.

Though the trap is only a small valve in the entire steam system, it has a great impact on the normal operation of the system and the cost of the equipment, so routine maintenance and inspection are essential, and good operating conditions of the trap are necessary to ensure that the energy-saving effect is achieved.

Watts 0821747, LF3100M3, 2.5" Lead Free Dielectric Galvanized Iron Flange Pipe Fitting with Brass Tailpiece, Iron Pipe Thread To Copper Solder Joint.

With expertise in valves and rich experience in the oil&gas, chemical industry, textile mills, power plants, and sugar mills. THINKTANK has become the premier manufacturer of next-generation precision control valves.

The thermostatic capsules and all other internal parts are made of corrosion-resistant stainless steel. Hastelloy membranes even resist acidic condensate conditions very well. There are generally three different types of capsules for thermostatic capsule steam traps.

Single-lever control of both hot and cold water to protect a washing machine’s hose and inner working parts. E-Z on/off ball-type design can also be used to throttle water flow and ease the water hammer shock caused by solenoid valves. Bronze construction. Equipped with fluoropolymer seats against brass thru-hole balls that provide quiet rotating action.

Wattswashing Machine Valve

Washing Machine Water Shutoff Valve(259) · Floodstop Point Of Use Water Safety Shut Off Valve For Washing Machines · Proflo Pfs11d 1/2" Washing Machine Water ...

The primary parts of bimetallic steam traps are a conical end stem valve and a composite material made of two plates with differing expansion coefficients. Bimetal components are crushed due to the cold fluid, and the valve is open. During this phase, condensate, non-condensable gases, and air are released. Bimetallic plates expand in distinct ways as the hot condensate enters the system, pulling the valve toward the seat and causing it to cease discharging. The cycle resumes when cool condensate reenters the steam trap.

STC series adjustable thermostatic trap is one of the products of thermostatic type. The temperature-sensitive element inside the valve is equipped with a temperature-sensitive mixture of a temperature-sensitive material, saturating agent, stabilizer, and filler, which is used to automatically close or open the valve by changing the state of thermal expansion and contraction in response to temperature. The temperature range for T condensate discharge is determined by selecting the appropriate specification, and then can be adjusted within this range with the adjusting screw as required.

With a customer base that includes over 42 of the world’s leading engineering&contractors and international valve brands, THINKTANK Valves offers cost-effective valves that help our customers achieve automated process control without paying high prices.

Application: City construction, chemical industry, metallurgy industry, petroleum industry, pharmaceutical industry, food&beverage industry.

As explained in quoting the ANSI/FCI 69-1-1989 standard, a trap is an automatic valve that automatically drains condensate from steam to the outside of the valve body while maintaining tight contact with live steam, if necessary, allowing steam to flow at a controlled or adjusted rate. Most steam traps are capable of draining non-condensable gases while maintaining close contact with the steam.

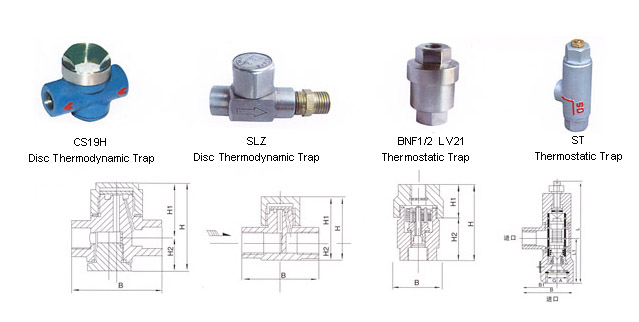

Steam traps are valves used in steam piping and equipment to automatically discharge condensate, air, and other non-condensable gases, and to prevent steam leakage. Based on the operating principle of steam traps, there are three types of steam traps as follows.

BA114. Edit. BA114. BA114-NO-SM. Effect: This card has no effect. HSP: 350. Series: HSP. Type: Normal Card. Attribute Bonuses: Pyrus: 0. Aquos: ...

Washing Machine ValveBox

TB5(3,6,11)F adjustable bimetal traps are used for steam mains, sub-cylinders, steam tracing lines, radiators, low-temperature heating tanks, crumb traps, etc.

The adjustable bimetal trap is operated by a bimetal temperature-sensing element that moves the valve plug to open and close. When the device is first started and low temperature condensate appears in the pipeline, the bimetal is spreading and the valve plug is in the open position under the spring force. When the condensate temperature is rising, the bimetal temperature-sensitive element starts to bend, and pushes the valve plug to the closed position. The trap closes completely before the condensate reaches saturation temperature. There is always high temperature condensate inlet of the valve, no steam leakage, and saves energy.

After earning my bachelor's degree in mechanical engineering from Zhejiang Normal University in 2008, l was fortunate enough to begin my career with Siemens, Fisher, and YTC, focusing on control valve accessories. Over the past dozen years, l've poured my heart and energy into understanding technology and fluid solutions for control valves. Now, as the marketing director for THINKTANK, a trusted branch of the Taiwan STONE valve group, I can't help butf eel proud of how far we've come. Our knowledge isn't just reaching professionals like engineer and valve distributors; it's also inspiring the next generation of automation college students. l genuinely hope you're enjoying our articles and finding them helpful.Your thoughts, questions, and feedback mean the world to me, so please don't hesitate to reach out to marketing[at]cncontrolvalve.com. Whether you're a seasoned expert or just curious about the field, I'm here to connect, share, and learn together.

An inverted bucket trap is an inverted bucket that is level sensitive, with the bucket opening downward and connected to a lever to drive the disc to open and close the valve. The inverted bucket trap is capable of discharging air, is free of water shock, and has good dirt resistance.

Heavy-duty type 330 water strainer with metal inspection lid.

In the start-up position, the steam trap opens fully to remove air and drain condensate. When the temperature reaches the pressure-dependent saturated steam level, the vaporization of the liquid inside the thermostatic capsule membrane generates a differential pressure that causes the orifice to close. As the condensate cools, the condensation of the liquid reduces the internal pressure of the membrane. The resultant differential pressure will benefit the external pressure that acts on the membrane by retracting and opening the orifice, which allows the condensate to drain and the cycle to continue.

The fluid in the capsule is adjusted to the pressure of the saturated steam temperature, and at superheated temperatures, the capsule may become stuck and not function properly, so it is not suitable for ultra-high temperature steam.

Washing machine valvereplacement

THINKTANK manufactures a wide range of steam traps, including inverted bucket traps, float, and thermostatic traps, controlled disc traps, and differential condensate controllers. Not only we can provide a quick quote, but also provide technical guidance on how to match the various types of traps and their benefits to your specific application needs.

I am the author of this article, and also the CEO and marketing director of THINKTANK, with 15 years of experience in the industrial valve industry. If you have any questions, you can contact me at any time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

Our technicians are licensed, bonded, and insured. We also offer maintenance plans with a range of perks as well as convenient financing options. To learn more ...

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

The CS41H Free Float trap is an automatic valve, especially for steam equipment with low pressure, low drainage, and high stability of temperature. The float steam trap is capable of discharging condensate from steam piping networks and heating equipment and preventing steam leakage. This product is widely used in petroleum, chemical, textile, printing and dyeing, pharmaceutical, pulp and paper, food, and other industries.

In industry, steam is often used for heating or as a driving force for mechanical power. So the main function of a steam trap is used in such conditions to make sure that steam is not wasted.

DualWashing machine Valve

The Bimetallic Steam Trap works by striking a balance between the opposing bi-metal force, which depends on temperature and attempts to close the discharge valve, and the steam force, which depends on pressure and tries to open the valve. The trap is calibrated so that the bi-metal force will prevail at saturated steam temperature while the force of pressure will prevail with under-cooled condensate and air and open the valve.

Armstrong's thermostatic mixing valves are designed specifically for use in non-return, "dead leg" applications. The range of products provides accurate ...

Proper installation of steam traps has a direct impact on the safe operation of traps and the productivity of the equipment. The following are 19 common installation precautions.

Steam is created when water vaporizes into a gas. To make the vaporization process happen, the water molecules must be given enough energy to break the hydrogen bonds between the molecules, and this energy to convert the liquid into a gas is called “latent heat”.

Standard design for any application requiring the use of saturated steam. This capsule discharges condensate 10°C below the saturated steam temperature at the relevant steam pressure.

SharkBitewashing machine valve

G3/4in Water Pressure Valve, Adjustable Water Pressure Regulator Valve with Pressure Gauge Greenhouse Garden Irrigation Controller.

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to [email protected]

202335 — Generally, water shut off valves are located near where water enters the house. It could be installed on an outside wall near where a water line enters or near ...

The steam leakage rate is less than 3%, the back pressure rate is 75%, there are more connections, and the sensitivity is not as good as that of the free float type trap. Because inverted bucket traps rely on the upward floating force of steam to close the valve, they are not suitable for use when the differential pressure is less than 0.1 MPA.

Specifically designed for applications where steam is used for heating. At the relevant steam pressure, this condensate is discharged at a temperature 30°C below the saturated steam temperature and allows the equipment to use the enthalpy of hot condensate.

THINKTANK Since 2005, offers over a decade of expertise in designing, manufacturing, and globally selling top-quality control valves, ensuring superior fluid control solutions.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

Order Watts Repair Kit, Watts Series 800 M4, 1 In, 800M4 1 1st Check Kit at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or ...

Washing machine Valvesize

Steam traps provide the basic function of condensate drainage in a steam system. A typical steam system is probably a complex network, and a trap must be matched to a specific drainage application, and we need to consider the various operating principles of steam traps as well as the specific needs and conditions.

We can ship anywhere the US Postal Service ships. For orders being shipped outside the US, please contact us at (888) ASK-NOEL, noelsplumbingsupply@fuse.net, or via the text widget on this screen.

The steam-based heating process uses latent heat and transfers it to a given product. When the work is complete, i.e., the steam has given up its latent heat, the steam condenses and becomes condensate. In other words, condensate does not have the ability to do work with steam. Therefore, if condensate is not removed as soon as possible, either in the steam transport piping or in the heat exchanger, the heating efficiency will be compromised.

Thermostatic traps use the thermodynamic properties of condensate to evaporate a second time when the condensate discharge is low. Only the viscosity and sealing aspects differ from the steam in driving the opening and closing elements.

Watts 887712; Repair Kit; 1-1/4-2" RK 800M4 S · Product Description · Product Videos · MPN · Product Reviews.

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

Specially designed for applications that require the use of dry steam, such as the tire industry and the textile industry. These capsules discharge condensate at the relevant steam pressure 5°C below the saturated steam temperature.

8615510865705

8615510865705

8615510865705

8615510865705