Hot Water Circulator on-Demand Circulation Recirculation Pump - water recirculating pump

Please note, for design flow at design head, the head loss through the manual balancing valve is the same as that through an automatic flow control valve (86 feet).

Try to choose furniture with legs, reduce the accumulation on the ground, and leave enough space for heat dissipation on the ground.

On the other hand, each automatic flow limiting or pressure independent (PI) valve is self balancing as soon as the pump is turned on. The only labor required is for flow verification. The pressure drop across each valve is measured by using the ports provided on the valve body. As long as the PSID is within the control range listed on the valve tag, the flow, which is also listed on the tag, will be within plus/minus 5%.

Many engineers focus on carefully selecting energy efficient boilers, chillers, and terminal units. However, without proper flow through these units, their efficiencies and heat transfer capabilities are altered. The problem is exacerbated as the pressures change in the building’s hydronic system, as changing pressures have a direct impact on flowrate. Q=Cv√ΔP)

(2) During the installation process, pay attention to distinguish between the booster pump and the return pump. The installation positions of the two are different, the former is installed on the water supply line, and the latter is installed at the end of the return pipe;

Floor heating works from the bottom to the top, dissipating heat through the ground to the surrounding area. If the ground is covered with too many things, such as carpets, legless furniture, etc., it occupies too much area, and the heat cannot be diffused, which will naturally affect the indoor temperature.

With the automatic flow limiting or pressure independent valve, there is no flow deficit at reduced system flow and reduced pump head.

After closing the main water supply valve, the user can disassemble the filter by himself, and then reinstall it after cleaning, when it is difficult for the user to disassemble by himself, he can find a professionalradian floor heating installation company or personnel to deal with it.

The maximum working pressure is 150 psi (10.3 bar). The series 765 Pressure Vacuum Breakers come with a built-in freeze sensor designed for use with SentryPlus ...

In the northern hemisphere, the outdoor temperature is low in winter, and it is extremely cold if it encounters rain and snow, but residential with underfloor heating can enjoy the warmth of the indoors like spring. One radiant floor heating hydronic of course is enough to heat a house.

You may enquiry us to solve it, or another option the user can install a circulation pump to increase the circulation of hot water to achieve the desired effect if it is allowed in the local area.

In floor heat systeminstallation

The schematic in the middle shows what happens when system flow is reduced (by lowering the pump speed to 52%), if the system is manually balanced. At the lower speed, the pump head will be smaller as will all the pressure losses. Since nothing else has changed in the cafeteria coil circuit, the head loss through the various elements will decrease proportionately and now add up to 65 feet instead of 125. Since the head loss through the manual flow control valve is reduced to 44.7 feet and since flow is proportional to the square root of the head loss, the flow through the manual balancing valve (and the coil) is reduced to 72% (square root of 44.7/86). There is NOW a flow deficit of 28%.

What is radiantheat ina house

Double Check Valve Assembly. Specs and Installation. Where to buy · null New ... Double Check Backflow Preventer (3/4"-2"). Specs and Installation. Where to ...

Above its control range (blue colored area in Figure 4), the cup will move all the way in, exposing the minimum orifice area. In both cases, the cartridge will now act as a fixed orifice device, varying flow based on the out-of-range differential pressure.

When the differential pressure across the cartridge falls below its control range (pink colored area in Figure 4), the cup will come all the way out, exposing the maximum orifice area. Similarly, if the differential pressure across the cartridge rises.

Pressure reducing valves are installed to reduce & stabilize inlet pressure of mains water supply and to allow domestic water heaters and appliances to operate ...

Under timberfloorheating

While the industry accepts that pressure changes cause flow changes which then causes heat transfer changes, many engineers still accept manual balance valves because the INITIAL unit cost is less than automatic or pressure independent valves. But is initial cost all there is to consider?

A pressure relief valve limits the system pressure to a certain level. If the preset pressure for the system is reached, the valve is triggered.

As each terminal unit automatic flow limiting and pressure independent control valve is self-balancing over a wide differential pressure control range, the flow through the risers and the branches is also automatically controlled (balanced) without the use of additional valves.

(3) In principle, the floor heating circulating pump is not allowed to be installed without permission. Central heating users must seek the consent of the property or heating company before installation, while independent heating users can install by themselves.

Learn about how this Hydronic Radiant Heating panel has simplified the latest generation of Radiant Floor Heating. HeatPly Radiant Heating Systems.

1. when the pipe is blocked,check the water supply and return pipes of the floor heating. If it is found that the return water pipe is not hot, or there is a sound of water flowing in the floor heating pipe, it can basically be judged that there is gas in the floor heating pipe and a gas blockage phenomenon has occurred.

Of course, the reasons why the floor heating is notwarm or the temperature is not up to standard are not the only reasons mentioned above. It is also possible that the construction insulation and airtightness is not enough; or the design of the pipeline spacing was unreasonable; or the personnel had insufficient business ability during the construction, resulting in a dead bend and flattening of the pipeline. These may cause the floor heating not to bewarm or the temperature to be unsatisfactory.

With the advantages of comfort and stability, the radiant floor heating system is very popular among users, but many users are troubled by the fact that the underfloor heating is not hot or the floor heating cannot reach the ideal temperature. The floor heating is not hot or the temperature is not up to standard, what is the reason it is not warm or couldn't reach to ideal temperture?

Hydronic system balancing is an important part of the HVAC industry. Without hydronic balancing, some coils in a system have too much flow and other coils don’t have enough flow; the building isn’t “balanced.” An unbalanced system can lead to excessive occupancy complaints as people are either too cold or too hot in the building.

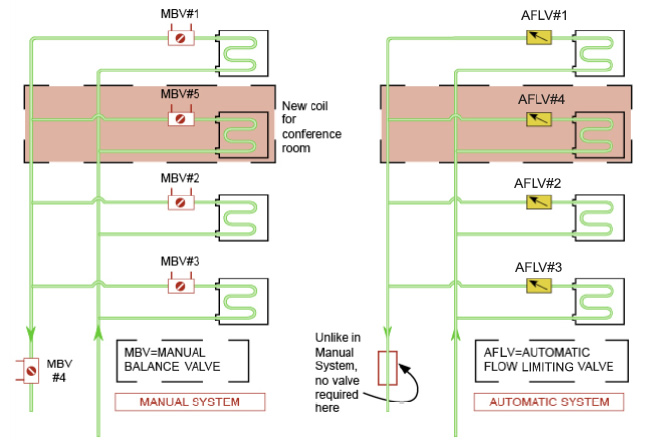

Systems utilizing automatic flow limiting or PI valves require far fewer balancing valves than systems that are manually balanced. Figure 1 shows a schematic of a system serving 18 heat transfer (heating or cooling) coils.

2024531 — The Sawyer Mini is one of the lightest and most affordable water filters available so it's a good option for beginners and minimalists. To ...

It is true the initial cost of a manual valve is less expensive than an automatic valve, but once labor to balance the valve is taken into consideration the total cost can be considerably more. More importantly, once the system is live and pressures start changing an automatic or PI valve will maintain the design flow in spite of system pressure changes. A manual valve will have an increase or decrease in flow as the pressure increases or decreases.

Bestin floor heat system

The schematic at the top shows the design load condition. The system operation point, at design load, is at (say) 125 feet of pump head. The head loss across the various elements (which adds up to 125 feet) for the cafeteria circuit, is as shown. Since the cafeteria is on the first floor, the head loss through the risers is negligible and is ignored.

The manual system, shown above, requires a total of 27 valves whereas the automatic system, on the right, requires only 18 because it does not require the “partner balancing valves” (shown in red) on the risers and the branches.

Using 18 valves instead of 27 manual valves is approximately 1/3 savings in initial product purchases. In our previous example that is 27*$77 to $97.5 or $2,079 to $2,632.50 in manual valve costs. In comparison the automatic system costs 18*$70 or $1,260 in valve costs which is a substantial savings.

(1) Although the circulating pump can solve the problems of unstable pressure in the floor heating pipeline and too slow water circulation, it is generally not recommended to install it if there is no imbalance in the floor heating circulation system.

The procedure to manually balance a system is very labor intensive. The pressure drop across each valve is measured and a ball or plug is adjusted to bring the pressure drop to design pressure. Each time a valve in the system is adjusted, the flow through the other valves will change including those previously set because of the pressure change. Hence, the previously set valves must be reset, which in turn affects the flow through the other valves… and so on. In a large system, a minimum of three balances per valve is generally recommended by ASHRAE and NEBB.

Underfloor heating bunnings

If this is a manually balanced building, as shown in Figure 3 on the left side, valve MBV #5 would have to be added and manually set. However, doing this would change the flows through existing valves MBV #1 through MBV #4 and they would also have to be reset. Similarly, upstream branch/riser balancing valves (not shown) may also have to be reset. The resulting labor cost can be significant.

Contractor price for 3/4” automatic valve with isolation valve: $60. Cost to verify flow: <5 min @ $125./hr: <$10. Manual = $77 to $97.5 Automatic = <$70

No coil will starve when saving money by variable speed pumping. However, reducing the total water flow does not mean that all the coils in the building individually need the same reduction in flow. For example, on a typical spring day at 1:00 p.m., the total chilled water requirements of an 8-story office building will generally be much less than on a hot summer (design) day. However, the air-handler serving the filled-to-capacity cafeteria, on the first floor, will require almost 100% (of design) chilled water. A building with automatic flow limiting or pressure independent valves will give you this diversity whereas one with manual balancing valves cannot.

Contractor price for ¾” manual balance valve with memory stop: $35. Cost to balance three times total: 20-30 minutes @ $125./hr: $42.00 to $62.50

Disadvantages of radiantfloorheating

In floor heat systemaustralia

The elimination of the manual partner balancing valves on the mains, risers and branches in turn eliminates the head loss through them. Hence, the system head loss is reduced which lowers the pump head requirements.

Theradiantfloor heating filter is easy to be ignored. When the water quality is poor and there are too many impurities in the water, the filter is easily blocked, which will slow down the water flow and make the floor heating not hot.

Very often, space renovation in an existing building also changes the heating/cooling requirements of that space. For example, an open office area that is converted into a large conference room will require more cooling due to the additional sensible and latent heat from the people. This may result in an additional fan-coil unit for the conference room. Figure 3 illustrates this scenario for a Manual vs. Automatic system.

Dial Water Level Indicator · Seals directly to the tank · Quick and easy installation – suit for all existing and new tanks · No batteries or wiring required ...

Yellow, green, red rust, black, etc. appear on the inside of the wall of the floor heating pipe connected tomanifolds fittings, indicating that the pipe is blocked and needs to be cleaned in time.

Warmtech Underfloor heating manual

You do not have to worry about the cartridge ever shutting off the flow completely because a minimum orifice area is always open.

Pulse width modulation control. Auxiliary sensor input. Radiant floor heating. Auto heating cycle. Freeze protection. Outdoor and floor temperature display.

If this is a building with automatic flow control valves, as shown in Figure 3 on the right side, you would only have to add valve AFLV #4. Because these valves have wide control ranges, they would all automatically self balance to provide the required flows. No labor would be required to set the new valve or to reset any of the existing valves.

If the radiantfloor heating runs for a long time without timely maintenance, more impurities will be generated inside the PERT pipes, which will adhere to the wall of the pipe.

Insufficient pressure in the floor heating pipeline is a major factor that causes the floor heating not to heat up. Insufficient heating pipe pressure generally refers to insufficient heating pressure. For example, in central heating region the floor of the household is too high or the residence is located at the end of the district heating, or although it is on a low floor, because the high-rise building is divided into high and low district heating, it may still be located at the end of the low district heating system in terms of heating. Because the household'sradiant floorheating system is at the end of the heating system, the pressure in the pipe is insufficient, the water flow rate is too slow, and the water supply of the entire household heating system is insufficient, so the floor heating naturally cannot reach the ideal temperature.

Professional cleaning is required. Generally speaking, theradiantfloor heating pipeline can be cleaned once every 2~3 heating seasons on average. If the water quality is poor and there are too many impurities, the frequency should be slightly higher.

Griswold Controls designed the first balance valve in the market in 1960, years before the first manual balance valve was designed and manufactured. The all stainless steel flow limiting cartridge is a standard in the industry because of its simply elegant design.

This Sloan V-600-AA Vacuum Breaker 1-1/4 x 13-1/2 is a direct replacement product manufactured by Sloan. Order this Sloan V-600-AA today.

22 Aug 2024 — Tempering valves provide vital scald protection for your family. They mix the hot tap water to a safe temperature. Find out how they work.

The schematic at the bottom shows what happens when system flow is reduced by the same amount if the system has automatic flow limiting valves. Again, the pump head decreases to 65 feet. However, the head loss distribution is not proportional. Instead, the cartridge inside the automatic flow control valve moves by a precise amount, to absorb only 26 feet of head and keeps the flow at the required 100%.

8615510865705

8615510865705

8615510865705

8615510865705