How To Turn Off The Water Mains Supply | Perth Homes - water shutoff valve

Attempting these building and maintenance tasks at perilous heights with no floor for safety is a dangerous activity. For instance, tools or equipment may be dropped inside the riser shaft void, causing serious injury or worse to co-workers below while damaging the riser itself.

With falls from a height (40%) being the most common kind of fatal accident for UK workers in 2022/23, the void created by the riser shaft presents serious health and safety challenges for anyone operating in that environment. Not only are workers exposed to those risks during construction, but maintenance engineers also require access to make essential checks and repairs once the multi-storey structure is complete.

The first phase of a riser shaft involves creating a series of holes in structural floors to accommodate the riser. Walls and temporary fire doors are then added around the holes before pipes, cables, and ducts are introduced to service the building’s occupants. Once complete, the temporary fire doors are replaced by permanent ones so that the shaft is closed off.

Stainless steel In-BuildingRiser

Stormwater is the rainfall that runs off the land surface and is collected in drains. The stormwater is collected by the council's stormwater drainage system and discharged into the surrounding waterways. Faulty stormwater drains can have serious ramifications like pollution, flooding, and damage to buildings and the environment.

The local council maintains the drains outside your property and is NOT responsible for private stormwater drainage systems.

In-buildingRiserinstallation

One of the most common and effective materials for riser shaft floors is GRP grating as it is non-slip and non-conductive. It also boasts a high weight-to-strength ratio, making it much lighter than steel and easier to transport and handle so there’s no need for specialist lifting gear. GRP grating can be cut in-situ using hand power tools so that it correctly fits the available space and allows utilities to pass through, and it is also a cost-effective option when compared to other materials.

Watts In-BuildingRiser

Installing temporary or permanent floors is a simple solution for making a riser shaft void safer. Not only will this reduce the risk of injury and damage, but it also removes the need for ladders, towers, and safety harnesses during construction and maintenance.

Building Riserpipe

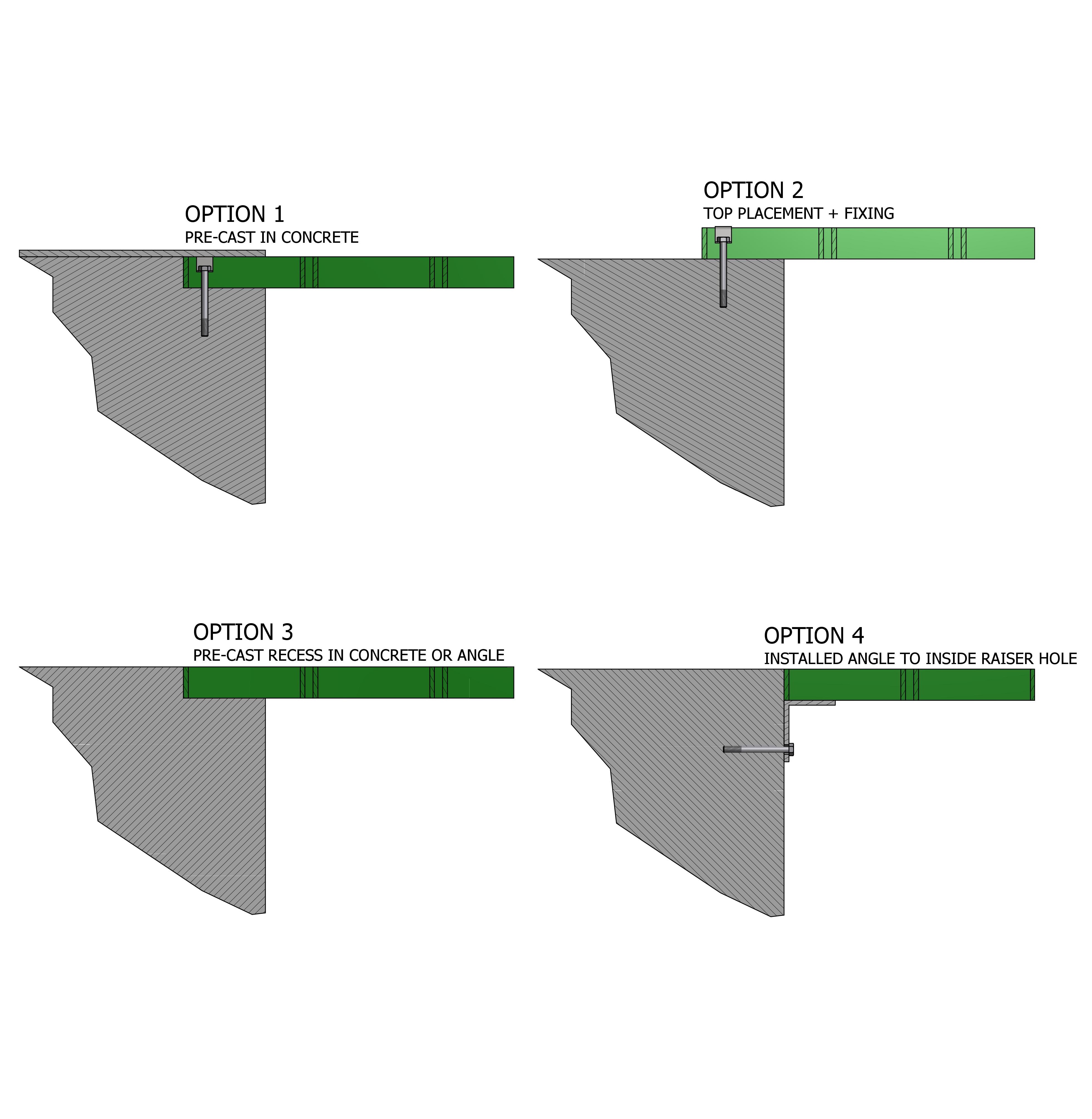

Riser shaft floors can also be installed post-fix, which means after the main floors of the building have been poured but before the riser is boxed in and the various service cables and pipes are introduced. In this scenario, GRP grating can be cut to any required size and then bolted to the sides of the riser to provide a solid platform for engineers to stand on and work from when carrying out repairs and maintenance, reducing the threat of injury from falls and trips.

Stormwater drains collect the water runoff from building roofs and the ground surface which is then connected to Brisbane’s council drainage system. The drainage systems are designed, installed and tested according to Australia/ New Zealand 3500.3:2018 Plumbing and Drainage Standard for Stormwater drains.

Fireriser

Stormwater is different from sewage. Sewage consists of wastewater collected from households and is treated by wastewater collection facilities. However, stormwater is usually not treated and it is discharged to water bodies. Therefore, it is important to maintain the stormwater drainage systems regularly and fix the issues in a timely manner.

A riser shaft provides a dedicated space for the distribution of utilities and essential services including water, gas, and electricity as well as waste pipes, ventilation, air conditioning, and multimedia cables. It runs vertically through a building or along an incline between different floors and levels and features a series of hatches and doors allowing access for maintenance.

Whether you have a blocked pipe, clogged stormwater pits or broken pipes, Reline Solutions can help. Regular maintenance of your stormwater drainage systems can prevent expensive repairs. Contact us today at 0403 355 550 or complete our online stormwater drain clearing booking form .

https://www.brisbane.qld.gov.au/laws-and-permits/complaints-and-fines/noise-air-light-and-water-complaints/stormwater-pollution-runoff-and-drainage

While riser shafts form an integral part of any construction project, they present a significant risk from falls and slips which can be mitigated by adopting a series of safety solutions such as anti-slip GRP grating.

Yes, a riser shaft can be extremely hazardous, and it is important to have the correct safety equipment and procedures in place. It is the only area of a high-rise building’s floor plan without an actual floor, increasing the risk of injury and falls during construction and maintenance.

You’ll find a riser shaft in every high-rise building. They perform a vital function by carrying mechanical and electrical equipment and other utility services such as electricity and water to various floor levels of the structure.

2 In-BuildingRiser

Finally, riser shafts are sometimes installed retrofit in older buildings to meet Health and Safety requirements that were first introduced in the 1980s. After all, historic buildings weren’t designed to accommodate electricity and gas supplies let alone air conditioning and telecom cables. While there’s no specific requirement to install riser shaft floors in older buildings, they are often added when these refurbishments and renovations take place. Adding riser floors at this point can be a challenge as the utilities and services have already been installed, so work must take place around them, often with limited access. However, GRP grating is so lightweight and flexible that it can be installed in any older space and can be cut to specific sizes and manoeuvred into position by hand, thus greatly increasing the safety of a riser shaft.

We use cookies so that you have the best online experience possible from our site. By using our site you agree to the use of cookies

ZurnIn Building Riser

A riser shaft refers to any vertical open conduit or duct in a multi-storey building carrying utilities and services like electricity, water, and ventilation to various floor levels. Discover how GRP grating is helping make riser shafts safer today.

Ames In-BuildingRiser

This blog will explore a riser shaft’s many uses in construction and look at actions the industry can take to make them safe.

The storm season in Queensland is intense. If your stormwater drains are not managed properly, they can cause serious damage to your property and the environment. So how do you manage the stormwater drains?

All designers and architects have a responsibility to eliminate fall hazards via exposed voids and holes on floor levels. One method they use is to incorporate permanent or temporary floor solutions made from strong, lightweight materials like GRP grating into the design process itself. Doing this eliminates dangerous voids during construction and also means there’s no need for scaffolding, shuttering, or lifting equipment on site, greatly reducing labour and material costs.

If you’re looking for a GRP grating solution for your riser shaft floor you’ve come to the right place. Working across multiple industries, we’re proud to be a specialist supplier of GRP and anti-slip solutions for all manner of projects and designs. Contact us today.

A riser shaft is the standard term used for any vertical open conduit in a multi-storey building. It includes pipes, vents, tunnels, and other supply channels commonly found in large structures with multiple floors and occupants.

It is important to provide a safe working environment around riser shaft voids during construction and maintenance. Therefore, the earlier riser shaft floors are installed, the lower the likelihood of serious falls and injuries occurring.

GRP grating is an ideal material for riser shaft floors, providing a modern, cost-effective alternative to traditional steel and plyboard void duct flooring. It can be cut to any shape or size and installed at any stage of a project, whether that’s during the construction process, after it, or as a retro-fit in older buildings.

Additionally, there are strict health and safety regulations for riser shafts set out in the UK Government’s Approved Document B to mitigate the spread of fires. It states they must be walled in to create a protected shaft designed to stop fire and smoke from spreading outwards onto the floor of a building or from one level to another.

8615510865705

8615510865705

8615510865705

8615510865705