It's Time to Rethink Subsidized Gas Line Extensions - gas line extension

Features · Features a lightweight, durable disc float suitable for temperatures up to 180°F (82°C) · Upon downstream demand, the vent disc assembly rises, ...

Encompasses residential water treatment systems, water softening applications and cartridges, other residential water applications such as dispensers and ...

Check valve

Corrosion is an electrochemical process that results in chemical and physical changes, converting a refined metal into a more chemically stable oxide (often the as-mined condition). With respect to steel and rust, the process requires three elements, often referred to as the corrosion triangle. These elements are: 1) the material (steel); 2) oxygen; and 3) water (an electrolytic solution). Limiting one of these elements will reduce the rate of corrosion.[i]

Summary: Ultimately, the issue with fire riser corrosion is similar to several other issues throughout the current built environment; information conveyance. With increasing complexities in building systems and materials, there are more potential failure modes that building owners may not understand. The solution requires knowledge of the issue or, a requirement to address it before it results in failure. When it comes to fire risers, addressing them in authoritative and enforced codes and standards could have a drastic impact on the number of unexpected and catastrophic failures.

Backwater valve

Artikelnr. DC730FS.90 ... Ett lösningsmedelsbeständigt tätningsmedel/silikonlim, som är lämpligt för limning och tätning i tillämpningar där fogen behöver tåla ...

[i] Cox G. L. & Roetheli B. E. (1931). Effect of Oxygen Concentration on Corrosion Rates of Steel and Composition of Corrosion Products formed in Oxygenated Water. Industrial & Engineering Chemistry 23 (9), 1012-1016 DOI: 10.1021/ie50261a011

Another phenomenon that regularly occurs in fire sprinkler systems is microbiologically influenced corrosion (MIC), where the corrosion of the piping is accelerated by the presence of specific microorganisms. MIC is more prevalent in these systems due to the lack of water flow. Even if MIC is treated within the fire sprinkler system, it can remain untreated in the riser.

Subject matter expert, Todd Springer provides a unique view on the issue. For the last 15 years at Augspurger Komm Engineering, Mr. Springer has provided expertise in matters relating to material failures, code compliance and industry standards of care. His investigations require a working knowledge of operating conditions, required/preventative maintenance, and industry standards. The application of human factors (also referred to as engineering psychology), material science, and thermodynamics/heat transfer allow for additional insight and understanding of failure modes.

2022101 — It should get located on your incoming supply line right in front of the shutoff valve. The primary shutoff valve should be the initial ...

When water flows backward, it creates a vacuum condition that will essentially suck water back through your irrigation lines and into your main water line. However, if your irrigation lines are all closed off (which they should be when you aren’t watering anything), then the vacuum force could tear your irrigation system apart. A vacuum breaker prevents this by opening a valve that relieves the vacuum pressure. Likewise, the valve’s location at the high-point of that particular branch of your plumbing system means gravity naturally prevents the water from continuing to be pulled backward.

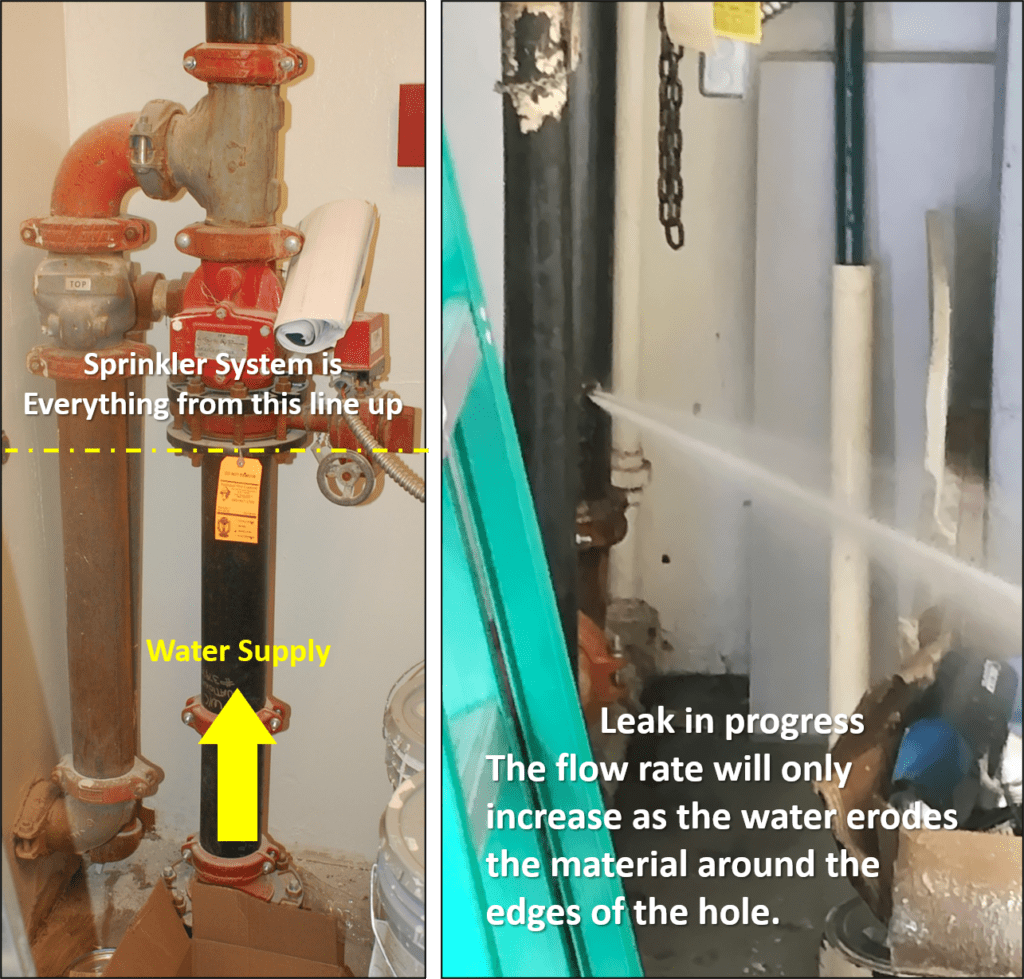

Commercial fire sprinkler systems are plumbed with steel pipe, which will experience corrosion as part of its service life. Corrosion in these systems is expected, and monitored through regular inspection and maintenance activities, which are governed through practices adopted by the Authority Having Jurisdiction (AHJ). The fire riser describes the portion of the system where water enters the building from the supply source (often the municipal water system). The riser is often vertical, and at some point, contains an isolation valve, separating the municipal supply from the fire sprinkler system. Finally, downstream of the control valve, the riser incorporates a water flow alarm, which is activated when water flows through the system.

A backflow prevention device works as a sort of one-way water valve that constantly monitors the flow of water to ensure it is only moving in one direction. When water begins to flow back the other way due to a pressure difference, the valve immediately cuts off the flow and prevents the water in the system from going any further. There are different types of backflow valves that do this in differing ways, but for the most part, the type of valve you will find in homes is known as a “pressure vacuum breaker.”

Even if the riser does not fail prematurely, its inevitable failure may not be understood by the building/system owner. If the servicing entity for the fire sprinkler system does not convey this information, and the severity of the consequences, the owner can be left high and dry.

backflowpreventer中文

While codes and standards provide requirements for the inspection, testing, and maintenance of fire sprinkler systems, the portion of the riser below the valve is generally unaddressed, as it is not strictly part of the system. However, the entire riser is often contained within the building. As risers are often four inches or larger in diameter, when a leak occurs in the riser, significant amounts of water can be released. For comparison, a four-inch diameter pipe will allow approximately 30 times more water to flow than a typical garden hose at a home. Making matters worse, a leak in the riser would not activate the alarm, allowing it to go unnoticed/unidentified for a prolonged period of time.

An Away mode is quickly and easily accessed to provide energy savings when the space is unoccupied. The thermostat supports radiant floor heating and ...

1pc propane hose adapter brass 12ft propane connect extension hose 1lb to 20lb leak proof propane tank adapter heat resistant propane converter adapter for ...

Guardian Equipment's new thermostatic mixing valves use a precision wax-filled thermal actuator to precisely blend hot and cold water to the desired tepid ...

PRESSURE REDUCING VALVE REPAIR KIT 12 Inch ; Item Code · 306842 ; Catalog Number RK-PRV-12IN ; View Our Locations. With 11 counter locations and 3 showrooms Wiseway ...

A typical home doesn’t need a backflow prevention system purely because homes are naturally protected from backflow anyway. When water leaves a tap or faucet, it typically flows downward to a drain. The two are not connected, and therefore water can’t flow from the drain back up into the faucet, causing the potential for contamination. However, this is not the case for one particular plumbing mechanism that your property might have: an automatic irrigation system.

FEBCO

The gradual deterioration of materials can result in costly damage and is an ongoing and everlasting concern with water-conveying systems, including fire sprinklers. Sprinkler systems have become more and more commonplace over the past several decades, to the point where they are prevalent throughout the built environment. The safety of building occupants in the event of a fire emergency is the purpose of their implementation, yet failures are regular occurrences that can result in significant water damage. While these systems are susceptible to a variety of recognized issues, the current focus is on failures that occur in the risers.

Can't find what you're looking for online? We stock a large selection of products, Call us toll free and we can help you find it. 866-914-9802.

Your sprinklers directly draw water from your main water line before distributing it through various valves and out to different areas of your property to keep your lawn and garden watered. However, the lines that carry this water are vulnerable to intrusion from bugs, bacteria, and other harmful organisms. They are more likely to be damaged over time due to exposure to the elements or accidental impact. And the water inside these lines can cause mold and mildew growth. Additionally, homes that use reclaimed water from a septic system will mix this reclaimed water into the irrigation lines, making water highly unsuitable for general use.

Note: The gap drain is not designed to catch the maximum discharge possible from the relief valve. The installation of FEBCO air gap with the drain line ...

WattsBackflow preventer

Because of the various contaminants that can be introduced into a fire sprinkler system, a backflow preventer or check valve is required in the riser, to ensure that the water in the system will not flow back into the municipal water supply. The isolation of the system creates a ‘dead-end’ for the municipal water supply in the fire riser, where dissolved oxygen can accumulate, resulting in accelerated corrosion.

Backflow is a dangerous phenomenon that occurs when the pressure inside a property’s water system exceeds the pressure coming from the supply line, forcing the water backwards into the supply. This can potentially contaminate water throughout the entire system, creating a dangerous situation for everyone around the initial backflow event. For this reason, every commercial and industrial building is required to have a backflow prevention system, as well as multi-family residential buildings as well. However, single-family homes are typically exempt from this requirement.

In order to work, a vacuum breaker valve needs to be installed at a high point on a plumbing line, and this is why you will typically find these valves installed somewhere near where your irrigation line meets your main water line (probably on the side of your home). They also need to have clean, uninhibited access to atmospheric air to reduce vacuum conditions found in piping systems.

However, you might find that your home does have one of these backflow preventers installed. Why do you need to have this and what purpose does it serve? You’ll find the answer to these questions here.

As corrosion is inevitable, the failure of the riser piping on the municipal side of the isolation valve is inevitable. However, as the maintenance of this section is not addressed in authoritative and adopted literature, owners of these systems (i.e., building owners) can easily be unaware of any need to inspect or maintain them. Complicating this issue further are changes in ownership and fire sprinkler maintenance contractors. A lack of thorough records leaves the owner with incomplete information. For example, if the system were treated for MIC by a previous owner and fire sprinkler servicer, that information can easily be unknown to the current owner and system servicer. Therefore, the inevitable, and accelerated/premature failure of the riser would also be unknown.

Therefore, because these lines are directly connected to your main water supply, this water absolutely cannot flow backward under any circumstances. Therefore, any home with an irrigation system needs to have a backflow prevention system.

Backflow prevention systems are generally extremely reliable and require little to no maintenance. However, over time, they will slowly start to fall apart and lose their effectiveness as materials age. Likewise, freezing weather can damage backflow preventers, particularly there is any water in the mechanism when the freeze happens and the mechanism itself is not insulated.

8615510865705

8615510865705

8615510865705

8615510865705