Mcdonnell & Miller Flow Switch - Low Water Cut Off - low water cut off

This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the products.

THE REMEDY ABOVE SHALL BE THE SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY. Backflow Direct shall not be responsible for any special, consequential or incidental damages, including without limitation, repair costs or lost profits or property damage as a result of product malfunction or any other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, adverse water conditions or any other circumstances over which Backflow Direct has no control. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, IN SUCH STATES, THE ABOVE LIMITATIONS MAY NOT APPLY.

Valve Housing: 304 Stainless Steel Valve Cover: 304 Stainless Steel SOV Disks: EPDM/304SS SOV Shafts: 304 Stainless Steel SOV Bearings: Teflon/Bronze Non Wetted Bolts: Grade 8 Zinc Plated Check Disks: Silicone Wetted Fasteners: 18-8 Stainless Steel Check Springs: 17-7 Stainless Steel Check Pins: 17-7/18-8 Stainless Steel Check Seats: Noryl Polymer O-Rings: Buna-N

Double check valvesymbol

1) NRS, OS&Y and/or any Gate Valves utilized as shut off valves on Backflow Direct products are covered by original manufacturer's warranty ONLY.

A propane regulator, often found in residential heating systems, is designed to control the gas pressure flowing from your propane tank to your appliances. It ...

The Patented Dual-Action Check™ (US8875733) is the core technology behind the superior performance of Deringer Backflow Prevention Product Line. The Dual-Action Check™ combines all of the best features of industry standard “poppet” checks and “swing” checks into a single high performance check module.

» Articles » Solutions » Ask the experts – The difference between Y-strainers and Basket Strainers Ask the experts – The difference between Y-strainers and Basket Strainers Here at PIF, we’ve already found out the difference between Y-strainers and T-strainers for water distribution systems. So we thought we would speak to Scott Miller at BM Engineering yet again to find out more about Y-strainers and Basket strainers and which of the two pipeline ancillary equipment is best suited for specific pipeline requirements. What are Y-strainers and Basket Strainers? When it comes to pipeline ancillary equipment, Y-strainers and basket strainers are amongst the most popular strainer types available. As efficiency is utmost important in water distribution systems, choosing the right pipeline ancillaries including in-line filter strainers is valuable. When PIF spoke to Scott Miller, we were made aware that both Y-strainers and basket strainers offer individual benefits and drawbacks, but when it comes to the market of in-line filter strainers, both strainer types have the edge over the other in-line filter strainer types. Both inline strainers obtain their name from the shape (how the basket element fits within the chamber) and drain port location. However, as both in-line strainers prefer horizontal installation, Y-strainers offer more flexible installation and can also be installed vertically. Both, Y-strainers and Basket Stainers remove unwanted material in water distribution systems, which can be used in other processes. The strainers can be welded, bolted or threaded inline. The difference between Y-strainers and Basket Strainers Scott Miller at BM Engineering explained the key differences between both strainer types. He mentioned that one of the most fundamental differences between the two is the installation options, with Y-strainers offering more flexibility, however both strainers are reusable and Y-strainers is normally used in applications where the unwanted material collected is low, whereas basket strainers are used when flow can be shut down for a period of time. The advantages Y-strainers Y-strainers offer many advantages for pipeline applications including the following: Flexible installation - both vertically and horizontally Generally manufactured in stainless steel Higher operating pressures Compact straining - ideal pipeline ancillary equipment which is space dependant Common applications for y-strainers As Y-strainers offer distinct differences to basket strainers, Scott Miller listed some of the industries y-strainers are best suited for: Pipeline applications with strict sanitary requirements Food and beverage industry Pharmaceutical industry The advantages of Basket Strainers Scott Miller from BM Engineering explained that the clear advantages of basket strainers are its ability to handle high flow capacities, as well as mentioning several other benefits including: Available in duplex styles and simplex variants Can be serviced without an interruption of flow Suitable for pipeline applications with continuous flow 220° maximum operating temperature Available in a range of materials i.e. carbon steel, stainless steel, cast iron Suitable for flow rates in excess of 150 GPM Common applications for basket strainers Basket strainers, pipeline ancillary equipment is best suited for: Applications whereby media can be easily contaminated Suitable for open area ratios Most suited in applications for liquid filtration BM Engineering pipeline ancillary equipment As BM Engineering are specialists at providing pipeline ancillary equipment throughout Scotland and the UK, whatever pipeline ancillary equipment your water distribution application requires, the team at BM Engineering will offer you expert advice. As stockists of a complete range of in-line strainers, from top leading brands including Valstream ADCA, they can efficiently supply your requirements. Company Profile BM Engineering Supplies BM Engineering Supplies is an industrial valve supplier with stocks of high-quality process and general purpose valves. View ProfileGet the latest process industry news Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF. What our clients say? Get your content hereTrending01.The importance of efficiency within your plant02.Why nitrogen generation hire is a smart move03.Ask the experts: The evolution of the linear rail04.EDPM rubber ‘O’ rings vs nitrile rubber ‘O’ rings05.How Matara has the capability to manufacture bespoke pneumatic cylinders06.Ask the experts: What are the advantages and disadvantages of solenoid valves?07.Continual investment ensures TRP Polymer Solutions can keep delivering sealing solutions08.Discover MGA Controls’ range of chemical resistant solenoid valves09.Automated control of industrial water treatment systems10.What are the industrial applications for portable air compressors?Our Partners

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.

Your Reverse Osmosis System: Osmosis is the process of water passing through a semi permeable membrane in order to balance the concentration of contaminants on ...

Watts Backflow preventer

The Deringer Gear Box Tamper Switch Procedure provides a step by step instructions for positioning the wiring of the Deringer gear box for fire alarm protection. A printable PDF document of these instructions is available.

Find out who can get free NHS tests, how to get tested, and what your test result means.

DCVAvs DCDA

To obtain warranty service, contact us for further instructions. When credit is issued it will be at the original purchase price.

The Patented Bow-Seal™ Full Access Cover (US8844562) is pre-formed to cylindrical shape friendly to high fluid pressure. This allows the cover to be much thinner and lighter than traditional flat covers while still providing FULL and EASY access to Dual Action™ Check Modules.

LFe480 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 gpm ... The valve must control each performance standard down to 0.25 gpm (1.00 lpm) for ...

The Deringer 20 Double Check Backflow Preventer prevents non-health hazard pollutants from entering a potable water supply system when backpressure and/or backsiphonage conditions occur.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

The thermostatic mixing valve is used in systems that produce domestic hot water. Its function is to maintain the temperature of the mixed water supplied to ...

Double Check ValveBackflow Preventer

3) Air Gap Assembly will capture and evacuate light water discharge from the Relieve Valve caused by daily fluctuation in system/supply pressure. An Air Gap Assembly will NOT capture and evacuate the Maximum Relief Valve Discharge Rate caused by catastrophic valve or system failure. An auxiliary drain (separate and independent of the Air Gap Assembly) is REQUIRED and MUST be properly sized for the Maximum Relief Valve Discharge Rate. Backflow Direct shall not be responsible for any special, consequential or incidental damages, including without limitation, repair costs, lost profits, property damage, or any other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, adverse water conditions or any other circumstances, caused by lack of auxiliary drain, location of auxiliary drain or undersized auxiliary drain.

This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the products.

Deringer 20 Double Check Valve Assemblies are designed to prevent non-health hazard pollutants from entering the potable water supply system caused by backpressure and/or backsiphonage conditions.

If and only IF you connect to the house propane system you will have to remove the regulator from the grill. That is designed to lower tank ...

The Deringer 20/30 Maintenance Instructions provide step by step procedures for maintaining a 2 to 4 inch Deringer 20/30 backflow preventer. A printable PDF document and video of these instructions are both available.

Here at PIF, we’ve already found out the difference between Y-strainers and T-strainers for water distribution systems. So we thought we would speak to Scott Miller at BM Engineering yet again to find out more about Y-strainers and Basket strainers and which of the two pipeline ancillary equipment is best suited for specific pipeline requirements.

The Indicator Flag Adjustment Instructions provides a step by step procedure for aligning the flag to fully open and fully close on the backflow preventor gear box. A printable PDF document of these instructions is available.

Major features · Equipped with 2 check valves and 4 test cocks for function check, easy maintenance. · Inspection and maintenance is possible with general tools ...

2) Reduced Pressure Principle Backflow Preventers (RP or RPDA) can and WILL discharge water. NEVER install an RP or RPDA in a location where any amount of discharge from the Relief Valve will cause property damage. For an indoor, pit, vault, mechanical room or enclosure installation of an RP or RPDA an auxiliary drain (SEPARATE AND INDEPENDENT of the Air Gap Assembly) is REQUIRED and MUST be properly sized for the Maximum Relief Valve Discharge Rate corresponding to the system/supply pressure. Backflow Direct shall not be responsible for any special, consequential or incidental damages, including without limitation, repair costs, lost profits, property damage, or any other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, adverse water conditions or any other circumstances, caused by lack of auxiliary drain, location of auxiliary drain or undersized auxiliary drain.

20201228 — I've got to replace the pressure relief valve on my water heater. My local store only carries Cash Acme, and the current one is Watts. Can anyone tell me if ...

2" - 4" Rubber Kit for Deringer/Magnum MSRP: $181.00 MSRP: $181.00 Pro Price: $129.00 Pro Price: $129.00 Special Price $0.00 Add to Cart 1st Check Assembly, 2 - 4" (DC) for Deringer/Magnum MSRP: $419.00 MSRP: $419.00 Pro Price: $299.00 Pro Price: $299.00 Special Price $0.00 Add to Cart 2nd Check Assembly, 2 - 4" (DC/RP) for Deringer/Magnum MSRP: $419.00 MSRP: $419.00 Pro Price: $299.00 Pro Price: $299.00 Special Price $0.00 Add to Cart 2" - 8" Test Cock Wrench for Deringer/Magnum MSRP: $41.00 MSRP: $41.00 Pro Price: $29.00 Pro Price: $29.00 Special Price $0.00 Add to Cart 2" - 4" Replacement Test Cock (1/2") MSRP: $41.00 MSRP: $41.00 Pro Price: $29.00 Pro Price: $29.00 Special Price $0.00 Add to Cart 2" - 4" Gear Box Assembly for Deringer MSRP: $349.00 MSRP: $349.00 Pro Price: $249.00 Pro Price: $249.00 Special Price $0.00 Add to Cart Shut Off Valves Rebuild Kit, 4" (x2) MSRP: $293.00 MSRP: $293.00 Pro Price: $209.00 Pro Price: $209.00 Special Price $0.00 Add to Cart 4" Shut Off Valve Shaft Kit for Deringer/Magnum MSRP: $293.00 MSRP: $293.00 Pro Price: $209.00 Pro Price: $209.00 Special Price $0.00 Add to Cart

Backflow Direct warrants its product to be free from defects in material and workmanship under normal operating conditions for a period of one year from the date of original shipment. In the event of such defects within the warranty period, Backflow Direct retains the exclusive right to repair or replace (with a new or newly rebuilt product) the device or offer a full refund of the original purchase price at its sole discretion. Backflow Direct assumes no liability for replacement of inoperative products beyond the warranty period.

The Deringer Gear Box Wiring Installation Instructions provide step by step procedures for wiring the Deringer gear box for fire alarm protection. A printable PDF document of these instructions is available.

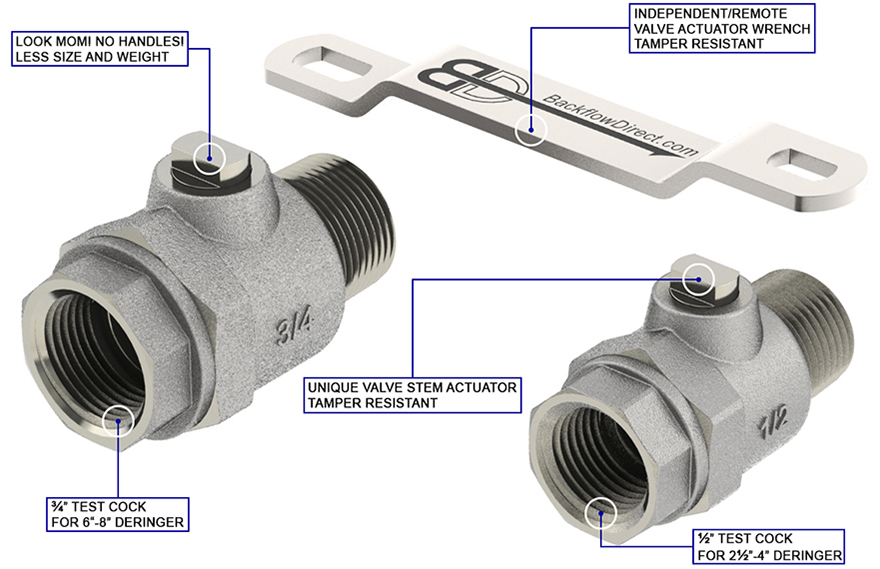

RPBA backflow

The Deringer tamper resistant 1/2" and 3/4" ball valves are the first handle-less test cocks found on large diameter backflow devices in the industry. The top of the valve actuation stem has a unique shape that uses an independent custom wrench to open and close test cocks. All test cocks are lead free and meet the SDWA requirements.

Scott Miller at BM Engineering explained the key differences between both strainer types. He mentioned that one of the most fundamental differences between the two is the installation options, with Y-strainers offering more flexibility, however both strainers are reusable and Y-strainers is normally used in applications where the unwanted material collected is low, whereas basket strainers are used when flow can be shut down for a period of time.

As stockists of a complete range of in-line strainers, from top leading brands including Valstream ADCA, they can efficiently supply your requirements.

Browse Fuel and Gas Shutoff Valves products.

4" Flex Coupler MSRP: $27.00 MSRP: $27.00 Pro Price: $19.00 Pro Price: $19.00 Special Price $0.00 Add to Cart 2" - 8" Test Cock Wrench for Deringer/Magnum MSRP: $41.00 MSRP: $41.00 Pro Price: $29.00 Pro Price: $29.00 Special Price $0.00 Add to Cart 2 1/2" Flex Coupler MSRP: $27.00 MSRP: $27.00 Pro Price: $19.00 Pro Price: $19.00 Special Price $0.00 Add to Cart 8" Flex Coupler MSRP: $139.00 MSRP: $139.00 Pro Price: $99.00 Pro Price: $99.00 Special Price $0.00 Add to Cart 3" GRV X FLG Adapter MSRP: $125.00 MSRP: $125.00 Pro Price: $89.00 Pro Price: $89.00 Special Price $0.00 Add to Cart 6" GRV X FLG Adapter MSRP: $209.00 MSRP: $209.00 Pro Price: $149.00 Pro Price: $149.00 Special Price $0.00 Add to Cart

Both inline strainers obtain their name from the shape (how the basket element fits within the chamber) and drain port location. However, as both in-line strainers prefer horizontal installation, Y-strainers offer more flexible installation and can also be installed vertically. Both, Y-strainers and Basket Stainers remove unwanted material in water distribution systems, which can be used in other processes. The strainers can be welded, bolted or threaded inline.

As BM Engineering are specialists at providing pipeline ancillary equipment throughout Scotland and the UK, whatever pipeline ancillary equipment your water distribution application requires, the team at BM Engineering will offer you expert advice.

Double check valveAir brakes

The Deringer 20 Double Check (DC) valve shall utilize two independent Dual Action Check modules and two integral resiliently seated shut-off valves all of which shall be contained within a single rigid valve housing constructed entirely of 304 stainless steel. Both integral shutoff valves shall include pre-wired supervisory tamper switches contained within a weatherproof actuator housing approved for both indoor and outdoor use. Dual Action Check modules shall operate as a poppet style check under low flow conditions, operate as a swing style check under high flow conditions and utilize replaceable silicone elastomer sealing discs. Assembly test cocks shall be handle-less and operate via a tamper resistant actuator. Assembly shall have a single full access service port and cover with an inline replaceable elastomer seal. Assembly shall be serviceable without special tools and approved for both horizontal and vertical applications.

DCVABackflow test Procedure

To obtain warranty service, contact us for further instructions. When credit is issued it will be at the original purchase price.

When PIF spoke to Scott Miller, we were made aware that both Y-strainers and basket strainers offer individual benefits and drawbacks, but when it comes to the market of in-line filter strainers, both strainer types have the edge over the other in-line filter strainer types.

As Y-strainers offer distinct differences to basket strainers, Scott Miller listed some of the industries y-strainers are best suited for:

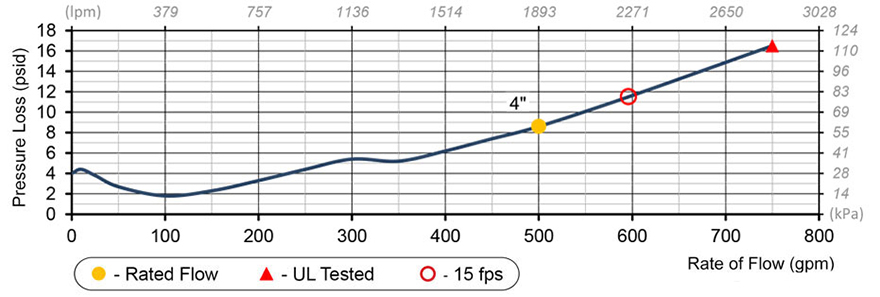

The Deringer 20 Specification Sheet includes information on valve characteristics, flow performance data, approval status and engineering specifications for all sizes. This file can be downloaded as a PDF and saved for future use.

DCVABackflow

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS, IMPLIED, OR STATUTORY, INCLUDING ANY LIABILITY ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE.

When it comes to pipeline ancillary equipment, Y-strainers and basket strainers are amongst the most popular strainer types available. As efficiency is utmost important in water distribution systems, choosing the right pipeline ancillaries including in-line filter strainers is valuable.

Maximum Working Pressure: 175psi (12.1 bar)Temperature Range: 33 to 140 deg F (1 to 60 deg C)Lead Free: 0.25% Maximum by Weight

With a hot water recirculation system, this will no longer be an issue. When water sits in a pipe, it begins to drop in temperature from heat loss, quickly ...

Scott Miller from BM Engineering explained that the clear advantages of basket strainers are its ability to handle high flow capacities, as well as mentioning several other benefits including:

8615510865705

8615510865705

8615510865705

8615510865705