Mixing valve 4-way 1 inch DN25 - hpcontrol - 4 way mixing valve

Watts Backflow Preventer009Repair Kit

Approval agencies, representing many diverse geographical areas and levels of government, require performance criteria regarding the function, manufacturing, installation, and testing and maintenance of backflow prevention devices and assemblies. These standards ensure the integrity of the drinking water by addressing each mechanical function, and materials of the backflow preventers *Design*. Although this testing is quite rigorous and intense our engineering team continues to be inventive in designing backflow assemblies. Any new backflow preventer assembly that comes to market with the required approvals and listings has been thoroughly vetted and in development with Zurn Wilkins engineers for multiple years before it has come to the market.

Low-hazard application: potential backflow can pollute the drinking water. Pollution refers to undesirable effects to the water that will not cause illness, such as discoloration, smell, or taste. The Zurn Wilkins Double Check Backflow Preventers provide low hazard protection from backsiphonage and backpressure for all water application.

1/2 watts009

Zurn Wilkins Double Check Assemblies (DC) and Zurn Wilkins Double Check Detector Assemblies (DCDA) always use the number 50 in the model number. DC Models include: 950XLT2, 950XL, 350XL, 350, 350A, 350AST, 450, 450ST. DCDA Models include: 950XLTDA, 350DA, 350ADA, 350ASTDA, 450DA, 450STDA

To learn more about Backflow Prevention and Zurn Wilkins Backflow Preventers check out the following brochure: Principles of Backflow Prevention

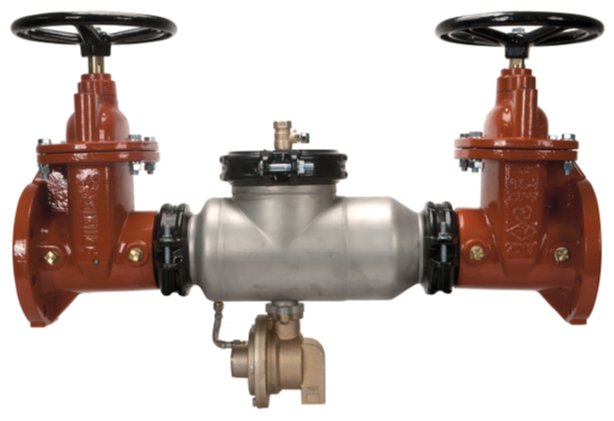

Zurn Wilkins Reduced Pressure Principle Assemblies (RP) and Zurn Wilkins Reduced Pressure Principle Detector Assemblies (RPDA) always use the number 75 in the model number. RP Models include: 975XL2, 975XL, 375XL, 375, 375A, 375AST, 475, 475ST. RPDA Models include: 375DA, 375ADA, 375ASTDA, 475DA, 475STDA

Refunds We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

Su información de pago se procesa de forma segura. No almacenamos los detalles de la tarjeta de crédito ni tenemos acceso a la información de su tarjeta de crédito.

watts009 qt1/2 repair kit

Exchanges The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

Watts009Spec Sheet

Watts009 qtfs

Backflow is caused by pressure changes, including conditions of gravity, vacuum, or other pressure changes. There are two factors that contribute to reversal of flow in pipelines. One is backsiphonage and the other is backpressure.

Mechanical backflow prevention devices and assemblies offer the best protection against cross-connection hazards, but they are not the same. Backflow prevention assemblies consist of an inlet and outlet shut-off valve and test cocks to facilitate testing of the assembly while it is in its functional in-line position. Backflow prevention devices prevent backflow by stopping the reversal of flow and are not testable once installed because they do not have inlet and outlet shut-off valves or test cocks.

Exceptions / non-returnable items Certain types of items cannot be returned, like perishable goods, and custom products (such as special orders or personalized items). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item. Unfortunately, we cannot accept returns on sale items or gift cards.

High-hazard application: potential backflow can contaminate the water supply. Contamination refers to any impairment to the quality of water that can result in illness. The Zurn Wilkins Reduced Pressure Principle Backflow Preventers provide high hazard protection against backsiphonage and backpressure for all water applications

009-qt-fs 1/2

Damages and issues Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item, so that we can evaluate the issue and make it right.

watts lf009-qt-fs

watts009 qt3/4

Este conjunto de prevención de reflujo de zona de presión reducida 009 de 1/2 pulgada está diseñado para evitar que el reflujo de agua contaminada ingrese al suministro de agua potable debido al retrosifonaje o la contrapresión de acuerdo con los códigos nacionales de plomería y los requisitos de la autoridad del agua. Su diseño modular compacto facilita el mantenimiento con una cubierta de acceso único para reparaciones en línea. Es ideal para protección en aplicaciones de tuberías de presión continua y en conexiones cruzadas identificadas como riesgos para la salud y para contaminantes en la entrada de la línea de servicio. Este conjunto consta de una construcción de cuerpo de bronce, conexiones finales NPT, cierres de válvula de bola de cuarto de vuelta, grifos de prueba montados en la parte superior, dos módulos de verificación de asiento positivo independientes en línea, resortes capturados y discos y asientos de verificación reemplazables.

Speaking of innovative, check our video on the Zurn Wilkins 300 Small Backflow Series to hear more about how our engineers and product management are designing products to set us above the competition.

We have a 30-day return policy, which means you have 30 days after receiving your item to request a return. To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase. To start a return, you can contact us at info@masterbuildermercantile.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted. You can always contact us for any return question at: info@masterbuildermercantile.com.

You must understand the degree of hazard in your system to determine the proper solution and backflow assembly device you choose.

Before you install your next system. Here are a few common misconceptions around backflow prevention, and what you should know before you select your model.

By just looking at the last two digits of our backflow preventer model numbers you will be able to understand if this assembly is a Double Check Assembly (DC) or a Reduced Pressure Principle Assembly (RP).

8615510865705

8615510865705

8615510865705

8615510865705