Order Propane Tank Accessories - propane tank with regulator

You will continue to receive e-mail notifications from us until such time as you unsubscribe. To make sure these e-mails are not sent to your bulk or junk mail folders, add news@iapmo.org to your address book. Requests for new subscriptions or change of e-mail address should be sent to news@iapmo.org. IAPMO does not knowingly participate in SPAM. We do not sell, rent or trade the names on our e-mail list; your e-mail address is only used to send messages from IAPMO. If you wish to be removed from this list, follow the link below.

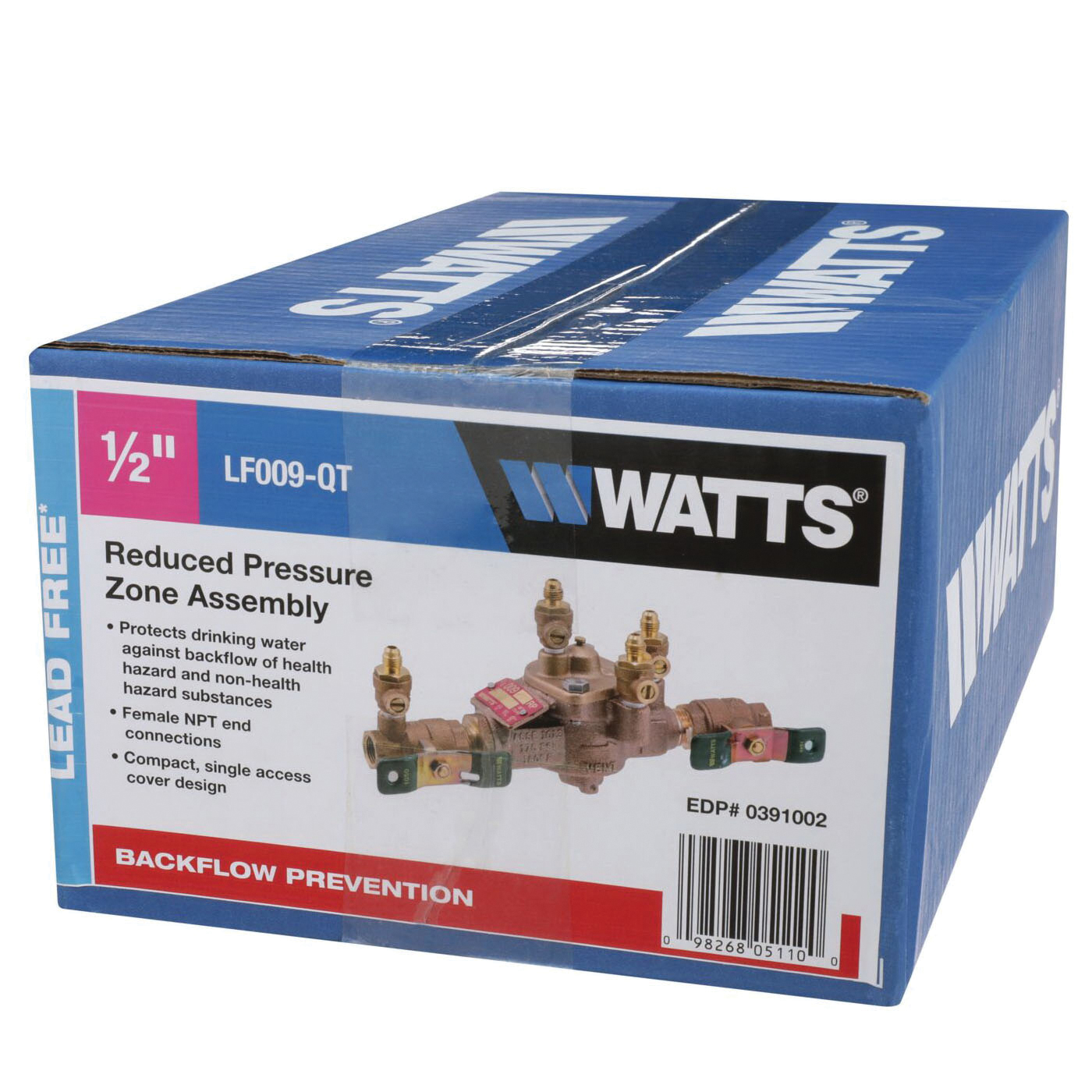

WATTS® Reduced Pressure Valve Assembly Backflow Preventer, LF009 Series, 1/2 in Nominal, FNPT Connection, Full Port, 175 psi, Cast Copper Silicon Alloy Body, Lead-Free, 33 to 180 deg F, 12-3/4 in L

All items that have been added to your shopping cart prior to the maintenance window, will still be present in your shopping cart once the maintenance is completed.

You will not be able to see pricing, product availability, place online orders, check account AR and order history, or register new users during this time.

Series LF009 reduced pressure valve assembly backflow preventers are designed to prevent the reverse flow of liquids in a plumbing system due to backpressure or back siphonage where there is a potential health hazard. Their compact modular design makes them easy-to install in tight spaces and the single cover, top entry design allows convenient access for maintenance. The seats are replaceable for economical repair and no special tools are required for servicing.

603.3.2 Atmospheric Vacuum Breaker (AVB). An atmospheric vacuum breaker consists of a body, a checking member, and an atmospheric port.

The purpose of a vacuum breaker is to stop backsiphonage. The atmospheric vacuum breaker (AVB) consists of a valve that allows air into the piping system for the purpose of stopping a downstream siphon (see Figure 603.3.2a). At the same time, a check valve is closed to the supply piping. A common design element is that the airinlet valve and check valve are nearly always the same mechanical component. A float rises with water pressure to seal the system for water to flow and drops with a lack of water pressure opening to the atmosphere.

8615510865705

8615510865705

8615510865705

8615510865705