Pressure reducer rebuild or replace - regulator n35b

Expansion vesselpressure

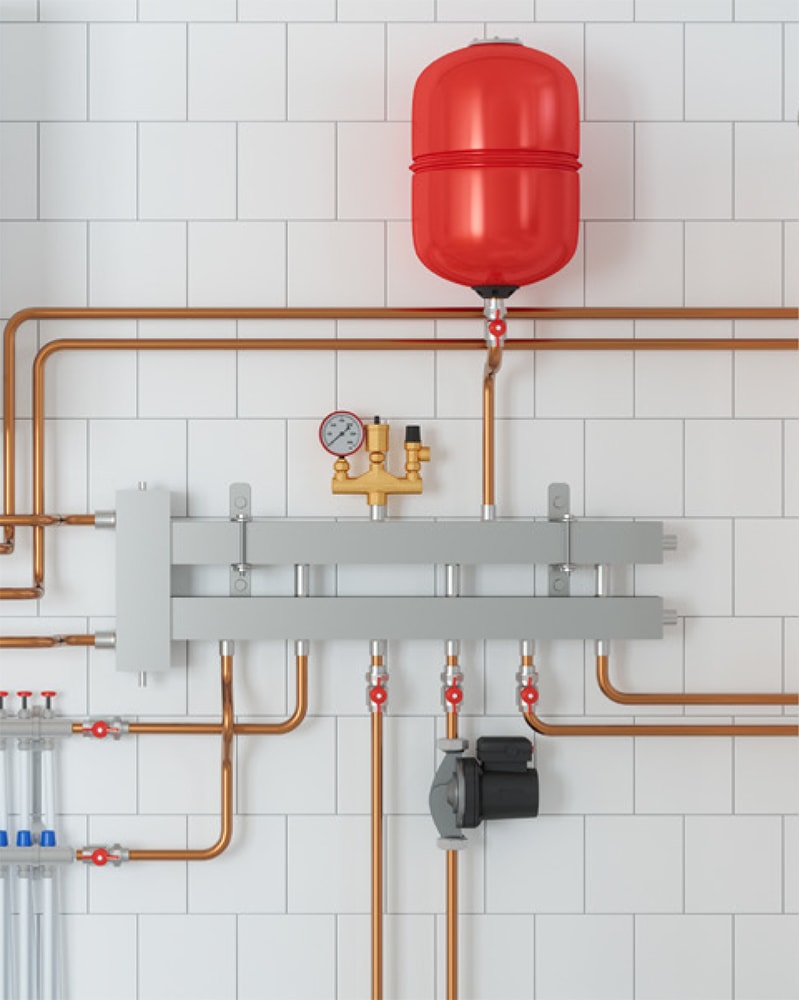

An expansion vessel, or expansion tank, is a device in a heating or cooling system that accommodates the extra volume of water produced when the system water is heated or cooled.

As the water heats up, it expands, and without a place to go, this increase in volume can cause a dramatic rise in pressure.

Be a part of the Taylor Team! At Taylor Water Technologies, we understand the importance of a workplace that considers the needs of the employees as much the need to achieve business results. Our wellness program focuses on the well-being of the whole person. We offer outstanding employee benefits which go beyond the customary health benefits package.

CASE STUDIES Greengate, UK "I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software. The ability to output the design straight into Revit assisted clash detection and coordination." Read the full case study

These vital components, also known as expansion tanks, are pivotal in maintaining system safety and operational efficiency.

Consider a system with a water volume of 500L, an initial temperature (T_initial) of 10°C, and a maximum operating temperature (T_max) of 80°C.

3 bar (300 kPa / 43.5 psi) is commonly used for this (recommended by CIBSE) but the manufacturer’s documentation is typically the best source for this information.

Combi boiler

The critical process of accurately calculating and correctly positioning an expansion vessel is crucial in designing and operating heating and cooling systems.

This data can usually be found within the system’s design specifications. In cases where it’s not readily available, a pressure gauge might be needed to measure this pressure.

The maximum allowable pressure is the peak pressure that a system can safely tolerate without causing damage to its components or risking a system failure.

– Incorrect positioning: this can disrupt the vessel’s primary function of accommodating fluid volume changes, potentially leading to dangerous pressure build-ups or operational inefficiencies.

Give your heating system designs the h2x advantage and experience the difference by booking a demo or by starting your free trial today!

Moreover, to avoid the issue of pump cavitation, installing the vessel on the suction side of the recirculation pump is recommended.

They counterbalance changes in fluid volume, and consequently pressure fluctuations, which occur due to variations in temperature.

Expansion vesselboiler

This number will vary based on your geographical location and the associated climate but will likely be around 5°C (41°F) in the winter months.

Having understood the crucial parameters, we now venture into the specifics of calculating the size of an expansion vessel.

Ideally, they should be placed in a cooler section of the system, for instance, the return pipe close to the boiler or chiller.

expansiontank中文

The transformation of industries by the digital revolution is a story told many times over, and heating system design is no exception.

CASE STUDIES Salon Republic, USA "The quality of the designs saw significant improvement with the adoption of h2x." "The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop." Read the full case study

Gain a comprehensive understanding of expansion vessels inside this informative blog. Includes a calculation example for practical insights.

Boilerexpansion vesselreplacement cost

In fact, there are a number of reasons. Taylor is a leading developer and manufacturer of water-testing kits and reagents for the pool/spa and industrial sectors. With unparalleled customer service and support, Taylor is the go-to for every distributor, retailer, commercial operation, and homeowner…wherever water is tested.

"The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop."

The expansion vessel provides the necessary ‘give’ in the system to handle this extra volume, preventing potential over-pressurisation damage.

"I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software.

Embracing the digital revolution in the form of heating design software, like that offered by h2x Engineering, is crucial for professionals who wish to stay competitive in the industry.

Activities at Taylor demonstrate a commitment to social responsibility. It is part of the Taylor way to build an internal community and give back to people around the globe through the efforts of the Taylor Foundation.

Hydronics

The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance."

CASE STUDIES Award-Winning Heating Design "Using h2x was pivotal, allowing for precise heat loss calculations, pipe sizing and flow rates for each room. This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort. The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance." Read the full case study

This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort.

As required by the 1986 Immigration Act, be prepared to present acceptable documentation upon hire showing your identity and that you are a U.S. citizen or an alien who is authorized to work.

Expansion vessels are required in systems where a closed circuit is subjected to a fluctuation in temperature e.g. heating and cooling systems.

With the right software, like h2x Engineering’s Heating Design Software, you can drive efficiency and accuracy in your heating system projects.

8615510865705

8615510865705

8615510865705

8615510865705