Pressure Relief Valves - GE Druck - pressure releif valve

When installing an HVAC system, it is necessary to measure the exact amount of constant flow required to size pumps, piping, and accessories properly. Without the proper flow control valves, system pressures fluctuate and deviate from the original system design.

ASSE1013 Backflow Preventer Parts

Most engineers opt for manual balance valves because their initial cost is less than automatic valves; however, they may fail to factor in the total cost of maintaining a manual valve system. When the system pressure changes, automatic valves maintain the design flow, whereas manual valves experience fluctuations in flow as the pressure increases or decreases. When considering ongoing system maintenance, it is far more cost-effective to verify the flow of an automatic valve than to manually balance a system using manual valves.

A good control valve, like those offered by our manufacturing partner Hays Fluid Controls, will not only be effective, but will also eliminate vibration, noise, feedback, and oscillation, with a design that ensures they won’t clog and can be backflushed.

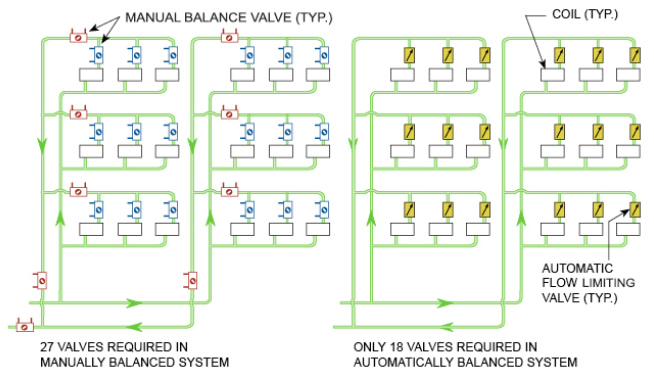

The manual system, shown above, requires a total of 27 valves whereas the automatic system, on the right, requires only 18 because it does not require the “partner balancing valves” (shown in red) on the risers and the branches.

Asse 1012instructions

Using an example contractor price of $35 for a 3/4" manual balance valve and $60 for a 3/4" automatic valve, the initial cost of 27 manual valves would be $945, while the initial cost of 18 automatic valves would be $1,080. However, once labor to balance the valves has been factored in, the cost of the manually balanced system could reach $2,633, whereas the price of the automatically balanced system would only be $1,260.

Installation of this product may require products from each of the categories below. Choose our top recommended product from each category, or choose "More" to see a full list from that category.

ASSE 1012vs 1013

Laiken is the Digital Marketing Specialist for the Hoffman Family of Companies. She learns more about the commercial/industrial HVAC industry each day and enjoys sharing her best findings here!

Asse 1012review

Hoffman & Hoffman, Inc., Hoffman Building Technologies, Inc., Hoffman Mechanical Solutions, Inc., and Heat Transfer Sales, LLC, are separate legal entities.

Asse 1012installation

A hydronic system needs to be balanced to ensure an even distribution of flow throughout the system. Without hydronic system balancing, some coils have too much flow, and other coils don't have enough; the system is unbalanced. An unbalanced heating or cooling system results in excessive complaints from occupants because they are either too cold or too hot.

It has been estimated by our manufacturer, Griswold Controls, that the contractor price to maintain a manual valve system could be up to $27 higher than that of an automatic valve system.

Engineers tend to concentrate on choosing the most energy-efficient boilers, chillers, and terminal units, but sometimes fail to consider the fact that their efficiencies and heat transfer capabilities are compromised without proper flow control.

A system using automatic flow limiting or pressure independent (PI) valves requires fewer balancing valves than one with a manual balance. Figure 1 (credit: Griswold Controls) shows a schematic of a system serving 18 heat transfer (heating or cooling) coils.

8615510865705

8615510865705

8615510865705

8615510865705