Pressure Relief Valves - pressure relief valve water

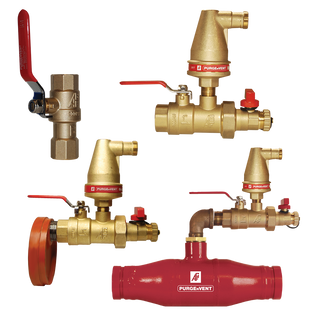

Starting in 2016, NFPA 13 requires the addition of one air vent on each wet fire sprinkler system that utilizes metallic pipe to help mitigate internal pipe corrosion due to trapped air. Developed with input from sprinkler fitter contractors and fire protection engineers, the AGF patented PURGEnVENT are UL Listed and FM Approved while being the most compact option on the market. Additionally, PURGEnVENT does not require a drain line, drip pan, or redundant air vents to prevent leaks. AGF offers three automatic air vents, Models 7900AAV, 7930ECA, and 7950ILV and one manual 7910MAV.

Optional collection assemblies with audible or visual notification for moisture expelled by the air venting valve while releasing trapped air.

AGF's PURGEnVENT air venting valves release trapped air from wet pipe fire sprinkler systems to help reduce corrosion. Air vents are now required by NFPA 13 (2016) in all wet fire sprinkler systems with metallic pipe. AGF offers a 1/2" manual air vent and a fully automatic air vent with flexible installation options.

Duplex strainersreplacement

To select basket screen perforation or mesh size, choose a size suitable for the job. A general rule of thumb is to choose a screen size that is slightly smaller than the smallest particle the system is expected to capture. Increasing size value for perforated baskets indicates a greater width for flow area better suited to capture larger particles. Increasing sizes for mesh baskets indicates more wire per inch and a smaller width for flow area better suited to capture smaller particles. Screens can be provided with mesh or perforation style engineering made from Monel®, Hastelloy® or titanium. These non standard options need to be requested. To request different materials or components for either Hayward® or Eaton® duplex strainers, contact us.

Duplex strainersaustralia

Professional grade duplex strainers provide continuous filtration and delivery of pipeline process fluids for high throughput and/or vital work applications. Duplex basket strainers are used for uninterrupted media flow in plumbing systems that cannot tolerate temporary shut down when cleaning of the equipment is required. They allow operations that need to be filtered and to run non stop the ability to do so efficiently. Duplex strainers are used to capture undissolved particles such as dirt, debris, scale, sediment, etc. and prevent clogging, dirtying, unwanted reactions or damaging equipment, ingredients, materials or chemicals located downstream within the pipeline. Duplex strainers are effectively two simplex strainers plumbed together and isolated by a three-way valve that controls the basket to receive the fluid flow for filtration. They are engineered where only one basket chamber at a time is ever active and operational. When one basket becomes full, a pressure gauge or other monitoring device can indicate cleaning is required and a simple turn of the valve handle will redirect flow to the empty basket. Duplex strainers are essential to the steady, clean and reliable performance of many industries, products and services. Common work applications for the duplex strainer model include chemical processing plants, power plants, cooling towers and lines, condensers, compressors, marine and maritime applications, oil burners, pumping stations, water treatment facilities, lubrication lines and many general industrial and manufacturing scenarios.

Available duplex basket strainers are engineered and made in the USA. They are fabricated by Hayward Industries, Inc.® or Eaton Corporation®, industry leading manufacturers of strainers and equipment. All duplex strainers come with drain ports, vents, integrated mounted feet and quick removable covers that do not need tools for access. Duplex strainers feature a compact, direct flow through design to promote easier integration into plumbing systems. Changing the active basket chambers for cleaning does not require tools and only requires turning the handle or lever associated with the valve system. The valve system is engineered with a no-error design that features integral stopping points to remove the guesswork in positioning so every maintenance flow change operation can be completed without issue. Available duplex basket strainers for sale include the Hayward® DB Series duplex strainer and the Eaton® Model 50, Model 52 and Model 53BXT duplex strainers. Hayward® brand strainers are ANSI / NSF 61 certified for potable water applications. Eaton® brand duplex strainers are American Bureau of Shipping (ABS) certified for maritime applications. Important features and specifications are outlined below based on the duplex strainer model:

8615510865705

8615510865705

8615510865705

8615510865705