Radiant Heating Systems - radiant heat system

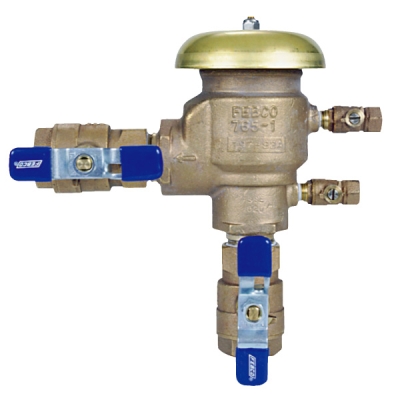

OperationThe Febco 765 PVB is designed to be installed to provide protection against backsiphonage of toxic or non-toxic liquids. It consists of a spring loaded check valve which closes tightly when the pressure in the assembly drops below 1 PSI or when zero flow occurs, plus, an air relief valve that opens to break a siphon when the pressure in the assembly drops to 1 PSI. Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

So what this means is that before I can remove the washer, I need to call a licensed plumber, he needs to come in, shut off the water to the whole building, he waits around for 2 hours so that the water can completely empty out of the building's pipes before he can proceed to do the small job. And he wants alot of money for it. Does this seem normal to you that unit owners have to pay exorbitant fees to do simple jobs like to remove a washing machine? Someone mentioned that just the fact that the building only has one shut off valve is a housing violation.

Washing machine shut off valveleaking

Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

Shop for Mueller Steam Specialty Y Strainer,27 5/8 H,0.062 Perf 4 758 N (1) at Ralphs. Find quality sporting goods products to add to your Shopping List or ...

1. Prepare to get wet. Actually, it was not bad. I stayed dry. Only a few gallons on the floor. 2. Work fast. Practice first if you don't usually do plumbing. 3. Use a shutoff valve made to connect PEX to copper. It has a compression fitting. You slip the connector and ring over the pipe, then screw connector together. Viola! Do this fast enough, you can have it on and in place in under one or two minutes. Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

There must be a water shut off to the washer. If you find it YOU BLAST the idiot that told you otherwise. If a LICENSED plumber told you this information and again if you do find a shut off, call the plumber and triple blast that good for nothing drunk for try to rip you off. John New Jersey I Luv Plumbers

The tekmar Steam Control 279 can operate a single on-off steam boiler or an on-off steam valve using outdoor reset. The control determines the on time of ...

washing machineshut-offvalverepair kit

There must be a water shut off to the washer. If you find it YOU BLAST the idiot that told you otherwise. If a LICENSED plumber told you this information and again if you do find a shut off, call the plumber and triple blast that good for nothing drunk for try to rip you off. John New Jersey I Luv Plumbers

Since I have no knowledge of plumbing, I rely on the super to give me information. When I feel that the information may not be 100% reliable, I come to this website to get some great advice. I will check for the things you have all mentioned. And FYI, ManateeAlley, this is not a troll post nor am I an idiot. Thank you all for your posts.

Plumbing in buildings are not always designed to allow each unit to be shut off individually. It's not just the lack of shut off valves, it may also be a limitation of the plumbing inside the walls. You shouldn't need a licensed plumber to do this. That is crazy. If the shutoff valve is on the premises(not owned by the city), then the building manager should be able to turn it on and off at will. Who mandates this? You don't need to wait 2 hours for water to drain. You turn it off, relieve pressure by opening a couple fixtures, then do your work.

I spoke to the super and he confirmed that I need a plumber. The plumber has worked on our building before (recommended by our super) so he knows the drill. When we had a washing machine water flood a few months back, there was a lot of water that escaped. I wondered why and now I understand. This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

When we had a washing machine water flood a few months back, there was a lot of water that escaped. I wondered why and now I understand. This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

2020324 — The check valve seats are sealed by an o-ring and threaded into the body. There is no reason to remove the seat unless it needs to be replaced.

I want to remove an existing washer machine and dryer from my condo unit since the apartment is only a rental and there have been problems with water damage before. I just found out though that there is no shut off valve in the individual apartments, just one shut off for the whole building. So what this means is that before I can remove the washer, I need to call a licensed plumber, he needs to come in, shut off the water to the whole building, he waits around for 2 hours so that the water can completely empty out of the building's pipes before he can proceed to do the small job. And he wants alot of money for it. Does this seem normal to you that unit owners have to pay exorbitant fees to do simple jobs like to remove a washing machine? Someone mentioned that just the fact that the building only has one shut off valve is a housing violation.

Why not call code and code enforcement if you find that this is true. I, like some of the posters to this thread have never seen a washer without a shut off valve at the wall where the washing machine hooks up to pipes in the wall.

Washing machine shut off valveautomatic

There is a good possibility your complex was originally built to be rental apartments with a common owner. The maintenance crew had no problem with one main shut off per building. Later the units were converted to condos with seperate owners. I am sometimes tempted to buy the rest of the building.

Home depotWashing Machine shut off Valve

Dielectric Unions ... You need to be a registered customer to order this product. Please Login to your account or click here to Register. Choose ...

If that really is the case, then shouldn't adding them be fairly trivial? Seems like you could turn the water off for a few minutes, add screw-on valves -- and then turn the water back on. I'd do that in EVERY apartment immediately. You just HAVE to be able to shut off water to the washer right there at the pipe. - John...

10 Mar 2008 — Great RO water with no waste. But I started to think how it would work and can't understand how it can be truly zero waste.

Discover the 3/4 inch lead-free Y pattern reduced pressure zone backflow preventer, designed to protect your potable water supply from contamination.

Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

2015825 — Sizing tables provided by the manufacturers, give the tank model number and size based on the water heater's volume and the system supply pressure.

9 Apr 2024 — The Waterboss Model 900 is the best high-capacity softener, especially if you value a quick regeneration cycle. This softener is designed to be ...

Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Home/Valves & Actuators/Pressure & Temperature Control Valves/Mixing Valves ... Powers™ HydroGuard® 6550068 LFMM430 XP Master Tempering Valve, 1-1/4 in ...

Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

At the building's last board meeting the members mentioned the one shut off valve system and I didn't realize what that meant until now. I also didn't realize that was probably the reason that they send out notices occasionally to shut off the water in the building. I spoke to the super and he confirmed that I need a plumber. The plumber has worked on our building before (recommended by our super) so he knows the drill. When we had a washing machine water flood a few months back, there was a lot of water that escaped. I wondered why and now I understand. This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

I can't even conceive of the hose bibs not having individual shut-offs. If they don't, they have to ALWAYS be hooked up to a washer. What happens when people move? What about when a washer breaks or wears out and a new one has to be installed. This doesn't make sense.

Washing machine shut off valvereplacement cost

You don't have a hot and a cold shut off valve at the washer connection where the hoses from the washing machine would connect to the hot/cold...should be to handle valves there...thats pretty standard operating procedure...

Who says you must hire a drunk with a Cracker Jack's license to shut off the main valve in the building and simply drain down the system? There must be a water shut off to the washer. If you find it YOU BLAST the idiot that told you otherwise. If a LICENSED plumber told you this information and again if you do find a shut off, call the plumber and triple blast that good for nothing drunk for try to rip you off. John New Jersey I Luv Plumbers

as stated in the opening post: "So what this means is that before I can remove the washer, I need to call a licensed plumber, he needs to come in, shut off the water to the whole building, he waits around for 2 hours so that the water can completely empty out of the building's pipes before he can proceed to do the small job. And he wants alot of money for it." Who says you must hire a drunk with a Cracker Jack's license to shut off the main valve in the building and simply drain down the system? There must be a water shut off to the washer. If you find it YOU BLAST the idiot that told you otherwise. If a LICENSED plumber told you this information and again if you do find a shut off, call the plumber and triple blast that good for nothing drunk for try to rip you off. John New Jersey I Luv Plumbers

Does this seem normal to you that unit owners have to pay exorbitant fees to do simple jobs like to remove a washing machine? Someone mentioned that just the fact that the building only has one shut off valve is a housing violation.

Washing machine shut off valvebox

Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Home · Tekmar 356 - MIXING CONTROL VARIABLE SPD. Skip to the end of the ...

Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

I understand not having individual shutoffs for each unit in a multi -- one of our 4-plexes is the same way. However, I have never seen washer connections that didn't have shut-offs right at the end though. In other words, not shutting off water for the whole apartment -- but just shutting it off for the washer. Are you saying that you don't have those? The connections that the washer hoses connect to are just pipes coming out of the wall with screw-on fittings on the end with no faucet?? Wow. That's crazy. If that really is the case, then shouldn't adding them be fairly trivial? Seems like you could turn the water off for a few minutes, add screw-on valves -- and then turn the water back on. I'd do that in EVERY apartment immediately. You just HAVE to be able to shut off water to the washer right there at the pipe. - John...

So what this means is that before I can remove the washer, I need to call a licensed plumber, he needs to come in, shut off the water to the whole building, he waits around for 2 hours so that the water can completely empty out of the building's pipes before he can proceed to do the small job. And he wants alot of money for it. Does this seem normal to you that unit owners have to pay exorbitant fees to do simple jobs like to remove a washing machine? Someone mentioned that just the fact that the building only has one shut off valve is a housing violation.

Who says you must hire a drunk with a Cracker Jack's license to shut off the main valve in the building and simply drain down the system? There must be a water shut off to the washer. If you find it YOU BLAST the idiot that told you otherwise. If a LICENSED plumber told you this information and again if you do find a shut off, call the plumber and triple blast that good for nothing drunk for try to rip you off. John New Jersey I Luv Plumbers

Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

When we had a washing machine water flood a few months back, there was a lot of water that escaped. I wondered why and now I understand. This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

2. Work fast. Practice first if you don't usually do plumbing. 3. Use a shutoff valve made to connect PEX to copper. It has a compression fitting. You slip the connector and ring over the pipe, then screw connector together. Viola! Do this fast enough, you can have it on and in place in under one or two minutes. Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

Come on, this has got to be a troll post. One idea for non-trolls who might need this in the future: "hose pinch off pliers"

Washing machine shut off valvereplacement

You shouldn't need a licensed plumber to do this. That is crazy. If the shutoff valve is on the premises(not owned by the city), then the building manager should be able to turn it on and off at will. Who mandates this? You don't need to wait 2 hours for water to drain. You turn it off, relieve pressure by opening a couple fixtures, then do your work.

You shouldn't need a licensed plumber to do this. That is crazy. If the shutoff valve is on the premises(not owned by the city), then the building manager should be able to turn it on and off at will. Who mandates this? You don't need to wait 2 hours for water to drain. You turn it off, relieve pressure by opening a couple fixtures, then do your work.

3. Use a shutoff valve made to connect PEX to copper. It has a compression fitting. You slip the connector and ring over the pipe, then screw connector together. Viola! Do this fast enough, you can have it on and in place in under one or two minutes. Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

If that really is the case, then shouldn't adding them be fairly trivial? Seems like you could turn the water off for a few minutes, add screw-on valves -- and then turn the water back on. I'd do that in EVERY apartment immediately. You just HAVE to be able to shut off water to the washer right there at the pipe. - John...

Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Do this fast enough, you can have it on and in place in under one or two minutes. Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

I spoke to the super and he confirmed that I need a plumber. The plumber has worked on our building before (recommended by our super) so he knows the drill. When we had a washing machine water flood a few months back, there was a lot of water that escaped. I wondered why and now I understand. This building was built in early 1980s and would like to know if this is a violation and if the building is partially responsible for the complications.

Washing machineshut-offvalvesharkbite

Susan, if the super told you this, I would fire him. We have a duplex with a common water supply but there are always shut offs throughout, at minimum at laundry hookups and toilet supplies and water heaters...guaranteed.

You don't have a hot and a cold shut off valve at the washer connection where the hoses from the washing machine would connect to the hot/cold...should be to handle valves there...thats pretty standard operating procedure...

There is a way to put shut off valves on without draining the whole system, just shutting the water off. I once had to put a new main shut-off valve on a house without even being able to shut off the water at the street. But with the water pressure for a whole multi-unit building, I'd at least get it shut off. 1. Prepare to get wet. Actually, it was not bad. I stayed dry. Only a few gallons on the floor. 2. Work fast. Practice first if you don't usually do plumbing. 3. Use a shutoff valve made to connect PEX to copper. It has a compression fitting. You slip the connector and ring over the pipe, then screw connector together. Viola! Do this fast enough, you can have it on and in place in under one or two minutes. Unlike soldering copper, this connection will work fine wet. Total cost under $20 for both. Assuming you have enough pipe to work with without cutting into the wall.

Does this seem normal to you that unit owners have to pay exorbitant fees to do simple jobs like to remove a washing machine? Someone mentioned that just the fact that the building only has one shut off valve is a housing violation.

Susan....alot of specifically asked and i assume you don't really know.... You don't have a hot and a cold shut off valve at the washer connection where the hoses from the washing machine would connect to the hot/cold...should be to handle valves there...thats pretty standard operating procedure...

8615510865705

8615510865705

8615510865705

8615510865705