regulator 50mm 10-30mbar aga6974 - gas prv

Grease Trapfor Sink

The collection of radiant PEX at F.W. Webb features tubing and accessories made from a versatile material specifically engineered to work with high-temperature heating systems. Commonly used by plumbers, builders, and do-it-yourself enthusiasts, PEX, or cross-linked polyethylene, is found in pipes, fittings, and tubings that support plumbing, HVAC, and boiler systems. Discover radiant PEX tubing and injection mixers for a boiler, heated flooring system, or radiant baseboard. PEX fittings connect one piece of tubing to another and come in an array of types and shapes to help make laying out your tubing easy. Find radiant PEX controls including valve actuators, control modules, and thermostats that keep your radiant heat set up at the perfect temperature. Radiant PEX manifolds come in sizes and valve capacities to suit rooms large and small, while PEX supports and PEX fasteners help reduce kinks and breakage as you run radiant heating tubes from one end of the room to the other. Find radiant PEX heating panels with aluminum backing for optimal heat retention and safety, and pre-fab indentations to accommodate the tubes. Or, opt for electric radiant mats for easy installation. Create a thermal barrier beneath your slab with PEX insulation or an easy-to-install insultarp. Lastly, complete your radiant heating set-up with a manifold cabinet. Select an in-wall cabinet or choose a free-standing option if you have the necessary floor space. Whether you're adding a radiant heating system for the first time, or simply updating your existing set-up, the collection of PEX supplies from F.W. Webb contains the tubing and accessories you're looking for.

Be sure to always get a quote first for grease trap pumping. Like every business their are always unscrupulous operators. A common scam of grease trap pumping companies is "skimming". Instead of the pumping company taking the complete contents of the grease trap the pumping company only takes off the very top layer of grease from the interceptor tank. Three quarters of the tank does not get pumped out. This practise will lead to the grease trap backing up and overflowing.

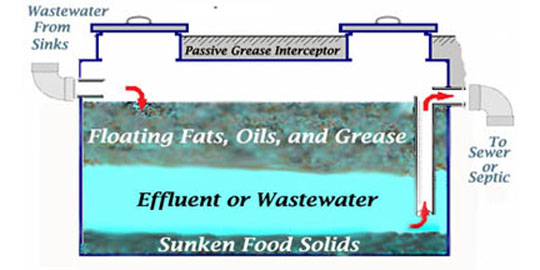

Passive grease traps are plumbing fixtures that contain pools of rotting food waste. Fats, oils, and Grease (FOG) are lighter than water and float to the top of the tanks.

In theory, yes, but most HVAC and heating professionals advise against using your PEX radiant heating system in this way. If you use PEX radiant heating to cool a room, you'll likely experience condensation which can be hazardous when walking and damaging to your flooring. Hydronic temperature control systems that offer both heating and cooling usually have a blower to prevent condensation on the floor.

greasetrap是什么

Conventional Grease Traps are referred to as passive grease traps and gravity based grease traps. Grease Traps were originally designed over 100 years ago. Grease Trap technology has remained virtually unchanged since the 1880's.

Ask to see the grease trap before the lid is closed. This may save you money and nasty inconvenieces. Choose a reputable and licensed grease trap pumping company.

Homegrease trap

Grease trap pumping is having a large liquid holding truck come to your foodervice facility. The truck,, equipped with a large tank, brings the hoses inside the facility to the grease trap. The complete contents of the grease trap are pumped back into the truck's tank. In-ground grease interceptors are pumped outside of the building. Grease trap pumping is typically performed when rank odours or grease blockages are discovered.

Thank you for your input, unfortunately we cannot respond to individual comments. If you need assistance, please Contact Us and we will be happy to help.

SmallGrease Trapunder sink

How to install agrease trap

Grease Traps were never designed to stop 100% of the grease from reaching the drain. A well maintained grease trap allows 15% of the grease in the wastewater to perpetually flow into the sanitary sewer. Grease traps at full capacity discharge 100% of the restaurant grease and wastewater into the sanitary sewer. When a grease trap is full of grease sludge the trap is incapable of capturing any grease or food solids whatsoever.

Passive grease traps and grease interceptors do not control the inflow of restaurant wastewater. During busy automatic dishwashing and sink draining periods restaurant grease bypasses the grease trap. Conventional grease traps do not have enough time to separate the FOG from the wastewater (retention time). The fast and hot outflow of wastewater from automatic dishwashers allows FOG to bypass the grease trap completely.

Stainless steel counters, sinks, dishwashers, and exhaust are a few of the restaurant standards in commercial kitchens. Inexplicably, Grease traps are made of steel, fibreglass, PVC and plastic. Rusted, leaking, or cracked grease traps cannot be easily repaired. Rusted grease traps must be replaced. Gasket and baffle repairs are frequent on conventional grease traps. Polyethylene or poly grease traps were designed and engineered to outperform other plastic materials. Common for mechanical stress in a polyethylene fixture is where a hole is cut to connect pipes, gaskets, and fittings. Polyethylene, though a strong chemical composition, does become brittle over time.

The most popular option used for radiating floor heating is ½-inch oxygen barrier PEX. Wide tubing, including ¾ and ⅝-inch PEX pipe, is generally reserved for large-scale commercial and snow melt applications.

Grease Interceptors are frequently sized at 1000 Gallon to 2000 Gallons for restaurant use. Grease interceptors are tanks made of cement, PVC or fibreglass that hold the fats, oil, grease, and food solids. The interceptor tanks are usually buried to the exterior of the restaurant.

Passive Grease Traps (above ground) are metal or plastic tanks required in foodservice facilities to prevent fats, oil, and grease from entering the sanitary sewer or septic system. Grease interceptors are large in-ground outdoor tanks that prevent FOG and food solids from entering the sanitary sewer or septic system at restaurant facilities.

greasetrap中文

Restaurant wastewater enters Grease traps from 3-compartment sinks and automatic dishwashers. The grease trap tank acts as a reservoir holding the wastewater and food solids that enter the trap. As the wastewater cools, the fat, oil, and grease (FOG) harden and the food solids settle. The FOG, being lighter than water, floats to the top of the grease trap. The wastewater is forced through the grease trap and out to the sanitary sewer. The FOG and food solids remain in the tank, increasing in volume daily. Food solids and grease sludge (brown grease) settle to the bottom of the grease trap.

Cockroaches arrive by the Sanitary sewer. Cockroaches feast on brown grease rotting in conventional grease traps and grease interceptors

SmallGrease Trapfor Kitchen

Greasetraps for commercial kitchens

If you take a bucket of water and pour in FOG, the FOG will float to the top of the bucket and harden. A grease trap functions in the same manner. FOG fills a grease trap from the top of the tank to the bottom. The FOG fills the grease trap from top down, displacing the wastewater from the middle of the grease trap and into the sanitary sewer or septic system. In-ground grease interceptors work in the same method but at a larger scale.

Part of the required install is an extension collar to connect the access hole at ground level and the grease interceptor approximately 30 inches below ground level. The access hole fitting is removed when the grease interceptor is pumped out. Approximate dimensions of a 200 Gallon grease interceptor are 65 inches (width) X 40 inches (height) x 32 inches (Depth). In total, with extensions a grease interceptor will sit between 70 and 80 inches below ground level. Grease interceptor pumping is a permanent on-going monthly expense. A 1500 Gallon in-ground cement Grease interceptor is pictured above.

Grease Interceptors fail between the 3-compartment sink and the Interceptor. The long length of pipe guarantees grease blockages.

Grease waste (brown grease) in a conventional grease trap is difficult to measure. Grease traps must be disassembled to view the level of waste inside the trap. Grease traps are required by law to be emptied or pumped out when the grease sludge occupies 25% of the tank.By-law enforcement have tools that measure the content levels of grease traps.

In most cases, underfloor hydronic and radiant heating systems take about a day to come up to their full temperature, although there are certain types that heat in as little as 30 minutes. Heating time is subject to the size of your room, the way your floor is constructed, and the type of PEX radiant heat system you have.

To install a grease interceptor a large trench must be excavated. A cement footing is built to support the grease interceptor. The interceptor is placed within the trench. Pea Gravel (3/8 inch gravel) is poured into the trench to occupy the space between the earth and the grease interceptor. A second cement slab is required at ground level. The cement slab at ground level is anywhere between 18 to 30 inches above the grease interceptor for various levels of support and potential traffic.

8615510865705

8615510865705

8615510865705

8615510865705