Reverse Osmosis (RO) Water Filters - ro filters

Watts 2000Flow Check Valveadjustment

We know how to narrow down the products that best fit YOUR needs, rather than push something simply because it’s easy. Once we’ve done that, we ensure you understand WHY we’re recommending the product by teaching you the concepts behind the product and in the process, we demystify all the terminology. Leaving you with confidence knowing you are making the right decision and one that is perfect for you and your goals of viewing the night sky!

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

Our Gear Experts have compiled a wealth of information to help expand your astrophotography knowledge! Below you’ll find links to articles, videos and "how-to" guides. Just one more reason that our Astronomy Hub is a one-stop-shop for all your astronomy and astrophotography needs!

Flange insert check valves are an extremely compact, wafer-style check valve for flanged piping. They are commonly used in-line and vary from ½ inch to 20 inches in size. This style is also considered a type of silent check that help prevent water hammer. Accordingly, they will have an internal spring that assists with closing of the valve. The flange insert check and its compact design allow it to be added to an existing system with minimum piping alteration required.

Pool heatercheck valve

Regardless of type or style of valve, the longest trouble-free service will come from valves sized for the application, not necessarily the line size. Ideally, the disc is stable against the internal stop in the open position when flowing or fully closed when no flow or checking. When these conditions are met, no chattering of the disc will occur, thereby preventing premature valve failure. Unfortunately, most check valves are selected in the same way on/off control valves are selected, by line size and the desire for the largest Cv available. This ignores the fact that unlike on/off control valves that have actuation (manual, pneumatic, hydraulic or electronic), only the flow conditions determine the internal performance of the check valve.

Whenever a metal part rubs against another metal part, wear is a result. That leads to eventual failure of the component itself. A component failure can result in the valve not performing its function, which in the case of a check valve is to prevent reverse flow. In extreme cases failure could result in the component(s) escaping into the line, causing failure or nonperformance of other valves or equipment in the line.

When installing check valves, point the flow arrow in the direction of the flow to allow the valve to perform its intended function. The flow arrow can be found on the body or tag. Make sure the valve type will work in the installed position. For example, not all check valves will work in a vertical line with flow down, nor will conventional or 90-degree T-pattern piston check valves perform in a vertical line without a spring to push the disc back into the flow path. The disc in some check valves extends into the pipeline when the valves are fully open. This could interfere with the performance of another valve bolted directly to the check valve. As we discussed earlier if possible, install the check valve a minimum of 10 pipe diameters downstream of any fitting or other piping system component that could cause turbulence. Notice, I said “if it’s possible.” After all, how many check valves have you seen bolted to the discharge of a pump? Many! A good source of reference for installing check and other styles of valves is MSS SP-92 “Valve Users Guide,” published by the Manufacturers Standardization Society.

Watts 2000flow Check Valve

This feature makes ball checks useful for viscous media. Ball checks are typically found in smaller sizes of 2 inches and less. Some designs include a spring to assist in closing and for use in 90-degree styles installed in vertical lines. Depending on the body design, pressure drops with ball types can be higher than with other types of check valves. Ball checks are available in various end connections including threaded and socket weld. Some body designs permit in-line repair/inspection.

Simply put, a check valve allows flow in one direction and automatically prevents back flow (reverse flow) when fluid in the line reverses direction. They are one of the few self-automated valves that do not require assistance to open and close. While some can be fitted with externally weighted and dampened devices for special circumstances, the majority do not have any outside assistance as found with on/off control or other valves. Unlike other valves, they continue to work even if the plant facility loses air, electricity or hydraulic pressure, or the human being that might manually cycle them.

SwingCheck valve

Swing checks are a simple design using a disc attached to an arm that is hinged at the top of the valve (at the 12 o’clock position). Reverse flow and gravity assist the valve in closing. Swing checks can be used for most media and generally provide good flow capacity. They should only be installed in a horizontal flow position. This is because they will not operate properly in the vertical flow positions. They also don’t tend to seal well in low backpressure applications. These check valves range in size from ½ inch and smaller to 50 inches and larger, and are available with threaded, socket weld, flanged or butt weld end connections. Swing checks are typically easy to inspect and maintain. In most cases, repairs can be performed with the valve in the line. Because of their design, swing checks are not fast-closing valves due to the travel distance from full open to close. This means they are highly susceptible to water hammer issues. Most swing check valves meet ANSI B16.10 face-to-face dimensions and will permit pigging of the line. There is a variation of the swing check called the tilting disc check. However, that version does not permit line pigging.

Taking time to contact the manufacturer to assist in selection can help you find the best fit. This is especially true if you are having problems with whatever type of check valve is presently installed.

20211130 — Hot water circulator pumps are powerful for water conservation, saving as much as 1000 gallons per person annually.

*W05 0391002 WATTS 1/2. 0391002. Watts 1/2 In. LF009QT Reduced Pressure Zone Assembly - Low Lead. $650.31 ea. Available: B/O. *W05 0391007 ...

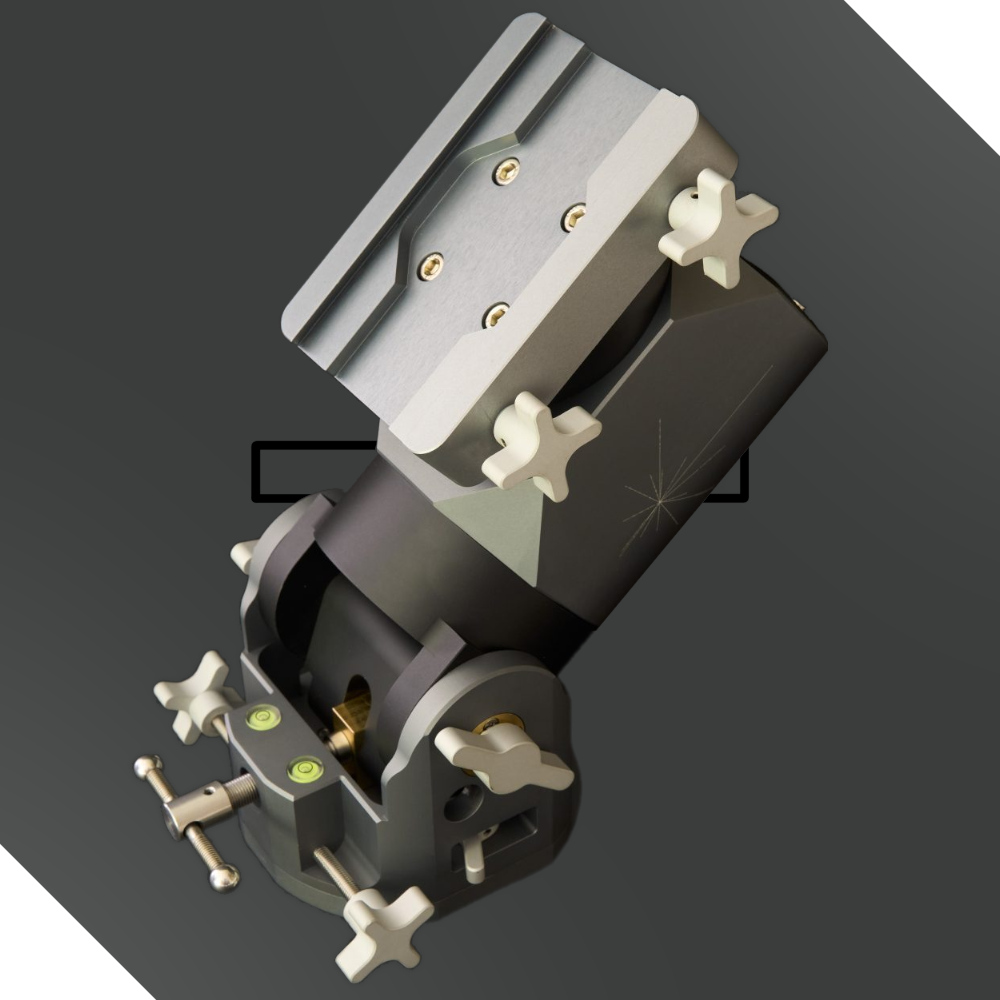

Please Note: This mount does not come with a tripod, and at this time WarpAstron does not make one for the WarpDrive line. This mount will need to be mounted to a tripod with a 3/8" thread and/or M6 screws. Please see the mechanical drawing in the image carousel above to ensure compatibility with your tripod of choice.

Cut the Tether—Wireless Smart Hand ControllerIf you're looking for a more hands-on form of control you're in luck, as WarpAstron have included a Smart Hand Controller! This can be connected directly to the mount for a more conventional hand controller experience, or can be charged up and used wirelessly for snag-free control. Manually control your mount, adjust its settings, and change from EQ to Alt/Az operation modes all with this handy accessory!

As with other types of valves, check valves are found in a full range of sizes, materials, and end connections. The line sizes range from 1/8 inch or smaller to 50 inches and larger. They are made of bronze, cast iron, plastics, carbon steel, various grades of stainless steel and alloys such as Hastelloy, Inconel, Monel and titanium. End connections include threaded, socket weld, butt weld, flanged, grooved, wafer and insert type.

Look, we get it. Stating that we’re the “best” can seem a bit like a catch. However, with a combined astronomy experience of over 115 years (117 to be exact), our team of telescope and astrophotography experts, a.k.a. "Gear Experts", knows astronomy and how to service our customers.

Harmonic mounts have become synonymous with high payload capacity for their weight and size, but the WarpAstron WarpDrive WD-20 pushes the envolop even further with servo motor power. Compared to the more commonly used stepper motor, these motors produce full torque more consistently and when combined with the harmonic gears allow the WD-20 to shoulder 44 lb. of gear while only weighing in at an impressive 11.9 lb.—or 66 lb. of gear when adding a user supplied counterweight! Supporting these harmonic gear reduced motor are encoders, ensuring this mount is just as precise as it is powerful. Not content to make something that only looks good on the spec sheet, Warp Astron have housed all this power in a 5-axis CNC machined 6061 aluminum housing with 304 stainless steel and ABS used through out for a construction that is sleek and as strong as the motors it houses!

Two of the most common problems with check valves are incorrect sizing or incorrect installation. Incorrect sizing comes in one of two forms. If the valve Cv is too small for the application, you would see a very high pressure drop which could lead to premature valve wear because of the high velocities involved. More commonly, if the valve Cv is too large for the application, there will not be enough pressure drop created across the check valve to fully open it. Any check valve that is not fully open has a high probability of chatter which will lead to premature valve failure. Incorrect installation involves not having the proper amount of straight pipe upstream of the check valve. Ideally a minimum of 10 pipe diameters of straight pipe upstream of the check valve is desired. This is to ensure a nice laminar flow going through the check valve. Shorter distances can cause flow turbulence and spin that can prematurely wear any style of check valve.

11 Nov 2019 — The purpose of the regulator is to control the flow of gas vapor from the container to the burner tip. The regulator ensures safety by providing over-pressure ...

Typically, pressure drop is calculated based on the check valve being 100% open as with on/off control valves. However, if the flow is not sufficient to achieve full open and the check valve is only partially open, the pressure drop will be higher than what’s calculated. This is due to the effective Cv of the valve being less than maximum when the check valve is partially open. In this situation, a large rated Cv actually becomes detrimental to the check valve (unlike with on/off control valves). This results in chattering of the disc and eventual failure. Such is not the case with some other valves. For example, with a gate valve that is fully open, the wedge is out of the flow path. Therefore, the flow through the valve does not affect the performance of the wedge whether that flow is low, medium or high.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Various types of check valves are available. Some of the more popular types are included below. All these can be used for clean media. As with other types of valves, specialty check valves can be found for unique applications. While no one type of valve is good for all applications, each has its advantages.

If the internals are missing or exhibiting excessive wear, two factors may be occurring. First, if the check valve selected does not have enough flow passing through to keep it against its stop, a valve with a lower Cv is needed to prevent the chatter of the internals. Second, if the check valve is used at the discharge of a reciprocating air or gas compressor, a specialty valve with a damped design or dashpot to handle high-frequency cycling is needed. Sticking can occur when scale or dirt is trapped between the disc and body bore. Leakage can happen from damage to the seat or disc or simple trash in the line. An elastomer is needed to provide zero leakage.

Check valves are found everywhere including in the home. If you have a sump pump in the basement, a check valve is probably in the discharge line of the pump. Outside the home, they are found in industries such as desalination, water and waste, chemical, food and beverage, geothermal, mining, oil and gas, power, pulp and paper, refining and more.

How does aflow check valvework

Direct Drive Harmonic GearingHarmonic gear reducers, also called strain wave gears, provide an incredible amount of torque in an incredibly small physical footprint. This technology allows the WD-20 to carry 44 lb. of gear in a package dwarfed by any conventionally geared mount in the same payload class. This impressive feat is without a counterweight; with an M12x1.75 counterweight shaft and counterweight (both sold separately) added, this mount can lift 66 lb. of equipment! This is all done with a system virtually free of backlash thanks to the harmonic technology and WarpDrive direct drive system, making this mount truly part of the New Wave.

Included AccessoriesThe Warp Astron WarpDrive WD-20 comes with a number of essential accessories to help you build out your astrphotography rig, with a 5.5x2.1mm to 5.5.x2.1mm 12V DC power cable, USB-A to USB-C cable for connecting your PC/control system of choice, a USB-C to USB-C cable for connecting the hand controller, and Smart Hand Controller included. Preinstalled on your mount is a dual D-Style/V-Style saddle. Making storing and travelling with your mount a stress-free experience is a hard carry case!

Our knowledge is only surpassed by our passion for this wonderful hobby we all love so much. We truly believe our team is a cut above the rest and we look forward working with you!

Examples of some other problems for check valves include reverse flow and water hammer. In both situations, a fast-closing valve is desired. Reverse flow can be costly, especially if it occurs at the discharge of a pump and the pump spins backwards. The cost to repair or replace the pump, plus the plant downtime, far exceeds the cost of installing the right check valve in the first place. With water hammer, you need a faster-closing check valve to prevent pressure surges and resulting shock waves that occur when the disc slams into the seat, sending noise, vibration and hammering sounds that can rupture pipes and damage equipment and pipe supports.

Various model available with various valve available on Request - Pressure Relief Safety Valve 1-1/4 Set @ 175 psi - Air Compressor.

Boilerflow check valve

Valve internals, such as seats and closures, are often at risk of erosion, abrasion, corrosion, galling and damage from cavitation.

Repair Kit Complete Rubber Part 1-1/4 to 1-1/2 Inch 0887309 for 009 Series Reduced Pressure Zone Assemblies

Boilercheck valvelocation

Ball check valves use a ball inside the body to control the movement of flow. This style is also considered a type of silent check. The ball is free to rotate, resulting in even wear and a wiping action between the ball and seat.

Sizes shown are for fin-tubed baseboard radiation. For systems with converters and/or unit heaters, increase tank one size. For cast-iron radiation, increase.

New Wave HarmonicWith its compact and lightweight construction, yet high payload capacity, the Warp Astron WarpDrive WD-20 is well suited to an On-The-Go powerhouse, allowing you to budget more room for a large scope or build an ultra-portable setup! At the same time this can be just at home on a backyard build, able to accommodate large telescopes without a counterweight (44 lb. payload capacity) or some truly staggering telescopes with a counterweight (66 lb. payload capacity), and able to connect with all the most popular control standards in use today. This incredible versatility earns the WarpDrive WD-20 a place in our New Wave Harmonic category, which you can read more about in our Astronomy Hub article here!

Because of this, elastomers should be considered for air/gas media and low-pressure sealing. Important considerations when using elastomers for such valves are service temperature and compatibility of the elastomer with the media.

Common check valve problems include noise (water hammer), vibration/chattering, reverse flow, sticking, leakage, missing internals, component wear or damage. However, it is worth mentioning that normally the real cause is the wrong size, spring, and/or style for the check valve application. In such cases, the problem is the application, not the check valve.

Like other valves, check valves are used with a variety of media: liquids, air, other gases, steam, condensate, and in some cases liquids with particulate or slurries. Applications include pump and compressor discharge, header lines, vacuum breakers, non-code pressure relief, steam lines, condensate lines, chemical feed pumps, cooling towers, loading racks, nitrogen purge lines, boilers, HVAC systems, utilities, pressure pumps, sump pumps, wash-down stations and injection lines.

That’s why our unbiased, non-commissioned product advisors’ only incentive is to recommend a product that they truly believe is the right choice to help you meet your goals, and at a price point that also meets your budget. There’s never any pressure to buy, and you can rest assured that your recommendation is personalized for you rather than motivated by financial gain. We look forward to helping you start your astronomy journey!

With its sleek anodized aluminum exterior and premium look the WD-20 certainly looks like a premier astronomy mount option, but Warp Astron have designed this WarpDrive mount for more than just stellar looks. From a powerful motion system, to wireless control and extensive compatibility, this mount is just as striking on the inside!

Check valves face a similar situation. Pins, stems, springs or other components that are constantly cycled can fail. That is why it is important to properly select check valves for their specific applications. Line size does not necessarily equal check valve size. A check valve with a high Cv in a low flow application is doomed from the start. It is not the check valve’s fault, it is the fault of the wrong selection for the application. The selected check valve would have worked fine in proper flow conditions. Unfortunately, the installed check valve is blamed for the failure, when in reality the culprit was the application. It is always best to review the application and service conditions with the manufacturer before purchasing a check valve to make sure the correct style and options are selected.

Lastly, I like to compare check valves to doors — whether that door is to your office or home. Typically, you open your office door at the start of the day and close it at the end, which is similar to what happens when a pump is cycled on and off. However, if someone stands at your door and constantly cycles it open and closed, what could happen? In most cases, the hinge pins would fail, since they are the weak link in the operation of your door.

Too often this valve is unjustly blamed when problems occur, but the real culprit is its use in the wrong applications. #gate-globe-check #basics

Hydroniccheck valve

Series 800M4QT FNPT Bronze 3/4 in. 150 psi BFP Vacuum Breaker. Fast #; Part ... Regulator Air Gap. Part #W909AGA. Item #216821. 5 out of 5 Customer Rating.

The WarpAstron WarpDrive WD-20 firmly takes it's place in the New Wave Harmonic category with not just the revolutionary gear reduction technology but whole host of other premium features. Dual axis encoders, GPS, a wireless hand controller, and a unique motor system all combine to set this mount at the leading edge. Jump into the future now with Warp Astron!

Wide Compatibility, Simple Setup The WarpDrive WD-20 mount sports a dual D-Style/ V-Style dovetail saddle, covering the two most common telescope bars on the market today to allow you to use most all popular scopes on the market! To make polar alignment a breeze, this also features easy to adjust polar alignment hardware. The base has been designed with polar alignment in mind as well, with a low backlash design that makes adjustments smooth!

Check valves are flow sensitive and rely on the line pressure and flow to open and close. The internal disc allows flow to pass forward, which opens the valve. The disc begins closing the valve as forward flow decreases or is reversed, depending on the design. The function or purpose of a check valve is to prevent reverse flow. Construction is normally simple with only a few components such as the body, seat, disc and cover. Depending on the design, there may be other items such as a stem, hinge pin, disc arm, spring, ball, elastomers and bearings.

main when pressures, due to thermal expansion on the outlet side of the valve, exceed the pressure in the main supply. Water Pressure Reducing Valve with.

Among the many factors to consider when selecting a check valve are material compatibility with the medium, valve pressure rating (ANSI), line size, application data (flow, design/operating conditions), installation (horizontal, flow up, or flow down), end connection, envelope dimensions (especially if replacing an existing valve to avoid pipe modifications), leakage requirements, and special requirements such as oxygen cleaning, NACE, CE Mark, etc.

Piston or poppet style check valves are available as inline, inclined (Y-pattern), or conventional (90 degree T-pattern) body designs. All types are considered a silent check valve style that prevent water hammer and reverse flow. It does this by using a spring-assisted disc in line with the flow that has a short travel distance, resulting in a fast-closing valve. As forward velocity begins to slow, the spring assist starts to close the disc. By the time the forward velocity reaches zero, the valve disc is closed against the seat before reverse flow can occur, preventing pressure surges in the line and thus preventing water hammer. Most designs can be installed in any position, including flow down if the proper spring is installed. Piston/poppet check valves are available from 1/4 inch to 24 inches and larger. The body design selected will determine the pressure drop; inline designs will provide the best flow performance. Piston/poppet check valves are available with multiple different end connections including threaded, flanged, weldable, etc. Special end connections are available, but you would need to consult with the check valve manufacturer. Some of these check valves can be inspected and repaired in line. Ideally, this style of check valve should only be used for clean media service with no particulate.

The water supply connection to each carbonated beverage dispenser shall be protected against backflow by a backflow preventer conforming to ASSE 1022 or by an ...

Our team of product advisors know what it’s like to buy astronomy equipment for the first time. There are so many types of telescopes and accessories that the process can be overwhelming enough without having to worry about pushy salespeople trying to make a big commission.

This article will explore the basics of check valves, how they work, what types there are, how to select and install them, how to solve their problems, and why they are not always the cause of the problem.

Bosch gas tankless water heaters are built to last and have lower operating and energy costs to provide sustainable home comfort.

Superior Servo PowerTaking things a step further than the tried and true stepper motor used in most other harmonic and conventionally geared mount on the market, Warp Astron outfitted the WarpDrive WD-20 with brushless DC servo motors. Where stepper motors lose more and more torque the faster they spin, the servo motors used in this mount can provide their full strength across the entire speed range. Servos also can function in colder temperatures, allowing this mount to function down to -13°F. Combined with high precision encoders on both axis, these powerful motors can provide both quick and precise motion without sacrificing performance. For remote applications the mount additionally features auto-homing sensors that allow the WD-20 effortlessly find home/zero position for you! Finally, to keep all your gear protected in the event of a failure is an RA axis electromagnetic brake.

Internal sealing of the check valve disc and seat relies on “reverse” line pressure as opposed to the mechanical force used for on/off control valves. Because of this, allowable seat leakage rates are greater for check valves than with on/off control valves. MSS SP-61 “Pressure Testing of Steel Valves,” published by the Manufacturers Standardization Society, is one standard used by manufacturers to perform seat and shell closure tests for check valves (as well as other valves). Factors affecting check valve seat leakage include reverse pressure, media, and what the seat material is made of (such as metal or an elastomer). Metal and PTFE seating surfaces generally will allow some leakage while elastomers such as Buna-N and Viton provide bubble-tight shutoff (zero leakage).

Center guided check valves are another type of silent check valve. They are also designed to prevent water hammer as well as reverse flow. This style is similar to the piston/poppet. It also falls under MSS SP125 & 126 for specifications. They are available in flanged styles with sizes from 2 to 24 inches and sometimes larger. Similarly, this style is best suited for clean media with no particulate.

Check valves may be the most misunderstood valves ever invented. If you mention check valves to most plant personnel, the typical response is “they don’t work.” In fact, those personnel may well have taken out the internals or repiped the system to avoid utilizing check valves. In other words, these valves may be the least popular valve in use today.

Check valve internals are flow sensitive, unlike on/off control valves. If there is not enough flow and pressure to fully open the check valve, trim chatter occurs inside the valve. This results in premature wear, potential for failure and a higher pressure drop than calculated.

Core Connections and Then SomeWarpAstron didn't stop with solid core functionality, packing the in premium features to cement the WarpDrive WD-20 mount's place as a leading option. With a built-in GPS, gone is the hassle of setting the time and location when moving the mount. For those looking to control their mount from a distance wireless control capabilities have been added, with the WD-20 able to connect over WiFi or Bluetooth. ASCOM, INDI, LX200, and INDIGO drivers are available, allowing you to integrate the mount with most of the popular computer control programs and systems*. To hardwire a connection to the mount Warp Astron have used USB-C, helpful for connecting cables in the dark due to the lack of a "correct" orientation. A second USB-C port provides a connection for the include Smart Hand Controller or a USB-C to ST4 adapter for ST4 autoguiding (adapter not included). Finally for power the WD-20 uses the industry standard 5.5x2.1mm 12V DC power port, making powering up your mount simple! * Please Note: The WD-20 can be made to work with ZWO's ASIAIR system, however full functionality is not guaranteed. Please see the attached manual for more information if you intend to use this mount with an ASIAIR.

8615510865705

8615510865705

8615510865705

8615510865705