Smith® 1020Y04 (-C-CID) 2020 Side Roof Drain, 4 in ... - side outlet roof drain

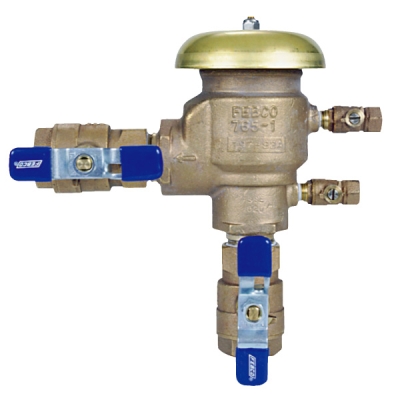

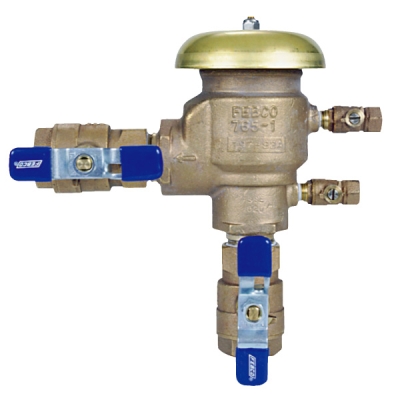

febco765-1 parts

In Australia, the water shutoff valve can be typically found right beside the water meter, as there is no danger of it freezing. In contrast, people who live in colder areas often have their water shutoff valve inside the house — a basement, usually — to prevent them from freezing. In milder climates, it is not uncommon for a water shutoff valve to be installed in an underground box or to an exterior wall.

Good for you if you do. If you don’t, then you’re one of the countless home owners all over the world who only find out the location of the water mains isolation valve when a plumbing emergency like a burst pipe takes place. It is likely that by the time you locate the water mains shut-off valve, your home will already have suffered a fair amount of water damage due to flooding.

More often than not, a water isolation valve is hidden in some dark corner of the house. While some water shutoff valves can be found on an outside wall in the utility area, most homes have their water shutoff valves located in the basement or in the garage.

Febco 765Manual

Here at Tradebusters®, our FREE and local tradesmen concierge service can help you connect with highly recommended plumbers and other trade businesses.

Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Febco 765parts diagram

Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Febco 765leaking

OperationThe Febco 765 PVB is designed to be installed to provide protection against backsiphonage of toxic or non-toxic liquids. It consists of a spring loaded check valve which closes tightly when the pressure in the assembly drops below 1 PSI or when zero flow occurs, plus, an air relief valve that opens to break a siphon when the pressure in the assembly drops to 1 PSI. Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

febco 7653/4

Whether you are renovating, buying, selling, or moving, The Sydney Top 3 Local Choice directory can help connect you with vetted and reputable local businesses with confidence.

Needless to say, it is extremely important for you to learn where turn off your home’s main water supply before anything like this ever happens. The water shut off valve is your only means of cutting off water supply to your house, especially in plumbing emergency cases. Here are some tips for finding your home’s water mains tap or shut-off valve.

Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

febco 7651 1/2 repair kit

Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

febco 765repair kit 3/4

Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Febco 765 PVBrepair Kit

It is an unfortunate fact of human nature that many among us only do something about anything when it’s already too late. Let’s take the location of our water shut off valve (or water mains valve) at home for example. As a home owner, do you even know where it is?

The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

If you don’t know the location of your mains water shutoff valve, much less turned it on and off since you moved into your current home, it is imperative that you make up for it straight away. That cliché about an ounce of prevention being better than a ton of cure certainly applies to this. Do not wait for a plumbing emergency to occur before looking for how to turn off your main water supply.

Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

8615510865705

8615510865705

8615510865705

8615510865705