Thermostatic Mixing Valves for Anti-Scald & Heating ... - 70a mixing valve

We at THERMODYNE ENGINEERING SYSTEMS provide the most energy efficient steam energy solutions which are best suited to your process. Our team of experts is always at a phone call distance to help you make your process energy efficient and reduce the steam energy loss by optimising the operation. Contact Us to increase your boiler system efficiency and reduce the operating cost.

speedtest测速

Precautions During PRV Installation: It is also important for you to know whether theinstallation of PRV is appropriate or not. Since an improper location of PRV may cause youlosses and would not have any benefits. Some of the basic factors you should take intoconsideration are as follows:

A sudden increase in load reduces the boiler pressure and increases the carry over and moisture content in the steam.The PRV eliminates this and allows constant pressure to be maintained in the boiler. Furthermore, generating steam at high pressureis relatively cheaper than using the low-pressure boiler, so it reduces fuel consumption.Now we have a brief idea of what benefits PRS serves. Any porous plug or orifice valve which reduces the cross-section area across the flow,works as a pressure reducer, but during the fluctuating loading, the outlet pressure of the valve will also fluctuate, which is not desirable,so to eliminate the above issue, we use the PRV, which provides a constant pressure during the variable loading also.

Internet speedtest

The following safety precautions should be taken when working with PRS systems:Always wear personal protective equipment (PPE) when working with PRS systems.Never operate a PRS system that is leaking.Always follow the manufacturer’s instructions when working with PRS systems.

Have you ever thought about why a technical consultant suggests buyinga high-pressure boiler? It then reduces the pressure by using thepressure reduction valve (PRV) to the required level as per the processrequirement. In general observation, it seems like a costincreasing step since you need to buy an extra device (PressureReduction System) and other extra fittings to install in the steam line.But it is not so!

The future trends for PRS systems include:Increased use of electronic PRS systems.Development of PRS systems that are more energy efficient.Development of PRS systems that are more environmentally friendly.

PRS systems can have a positive environmental impact by reducing the amount of steam that is wasted. Steam that is wasted can contribute to air pollution and greenhouse gas emissions.

Bluebook must be installed before test day. This digital testing application supports testing on Mac and Windows devices, iPads, and school-managed Chromebooks.

In preparation for taking the SAT, you'll need to familiarize yourself with the Bluebook testing application as well as the approved devices and operating system requirements. You'll also need details on borrowing a device if one isn't available to you.

A pressure reducing station (PRS) is a crucial component in industrial boiler systems, responsible for regulating and reducing steam pressure to a safe and usable level before it enters the boiler. This critical function ensures optimal boiler performance, safety, and efficiency.

test中文

Steam generation at high pressure helps you to reduce the initial investment cost since at high pressure the specific volumeof steam is lower than that at low pressure, which requires a small diameter pipe to carry the steam and reduces the cost associatedwith the pipe , which leads to a reduction in the initial investment cost. The high-pressure steam generation allowsrelatively less carryover and provides better-quality steam, as at low pressure, carryover is more likely to occur. Using a high-pressureboiler allows you to use the steam in different applications at different pressures by using the PRV. It also provides theflexibility for variable

test什么意思

A PRS system is typically installed in the steam line between the boiler and the process equipment. The PRS system should be installed in a location that is accessible for maintenance and inspection.

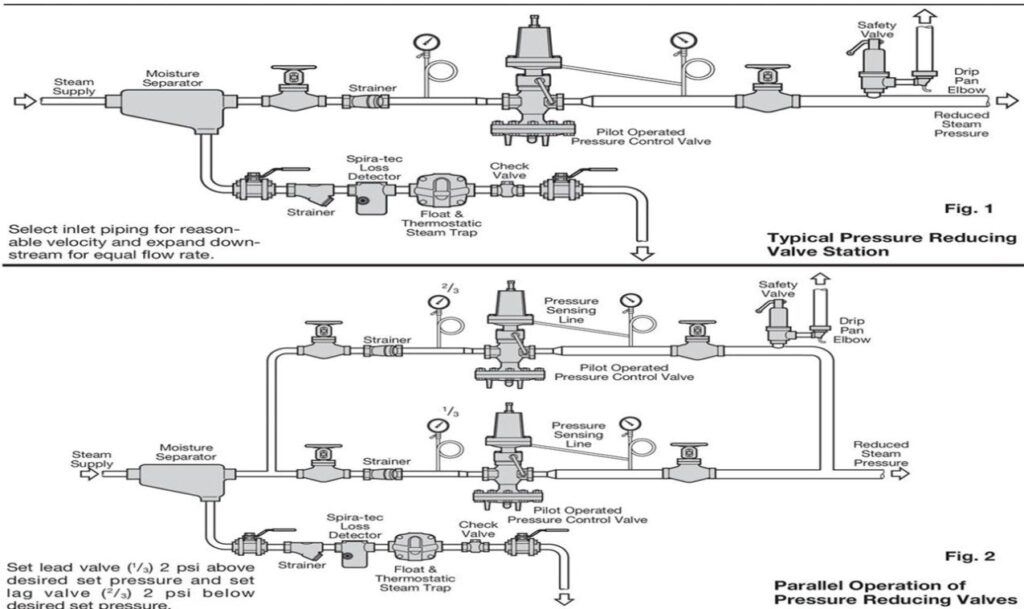

A pressure reducing system, achieved through a pressure reducing valve, helps to lower the inlet pressure to a desired and consistent outlet pressure. When the inlet pressure exceeds the desired outlet pressure, the valve opens to release the excess pressure. Conversely, when the inlet pressure drops below the desired outlet pressure, the valve closes partially or fully to restrict the flow and maintain the set pressure. This system ensures that downstream equipment or processes operate within safe and desired pressure ranges. The pressure reducing valve consists of a diaphragm or piston, a spring, and an adjustable setpoint to regulate the valve opening and pressure levels.

Find answers to frequently asked questions about the SAT in relation to student preparation, test day expectations, sending scores, and more.

The key to successful preparation for the SAT is practice. Find tips on how to study for the SAT using full-length practice tests on Bluebook, downloadable forms if you're approved to test on paper, and Official Digital SAT Prep on Khan Academy®.

test用法

There are two main types of PRS systems: mechanical and electronic. Mechanical PRS systems use a pressure regulator valve to reduce the pressure of steam. Electronic PRS systems use a controller to monitor the steam pressure and adjust the pressure regulator valve accordingly.

3. Reduced Carry Over: Low pressure boilers are more prone to carryover. The PRSreduces the boiler carry over by allowing us to generate the steam at high pressureand ensure the contaminants free steam reaches the process. Since carry overreduces the life of the valves, strainers, and pipes, so PRS also improves the life ofthe system indirectly.

A PRS system should be inspected and maintained on a regular basis. The frequency of maintenance will depend on the type of PRS system and the operating conditions.

“Thermodyne Engineering Systems, an ISO 9001:2008 certified company with enhancing Energy Efficiency, is a trusted name in Indian Boiler Industry. Thermodyne Boilers is one of the top 10 industrial steam boilers manufacturer, supplier & exporter in India.

Thermodyne Boilers is a renowned manufacturer of industrial boilers, including pressure reducing stations. They recognize the critical role of PRS systems in ensuring boiler safety, efficiency, and environmental compliance.

Fast speedtest

SpeedtestGoogle

PRS problems can be prevented by:Regularly inspecting and maintaining the PRS system.Using high-quality components.Installing the PRS system in a safe and secure location.

A pressure reducing station is an indispensable component in industrial boiler systems, ensuring safe, efficient, and environmentally responsible steam utilization. By precisely regulating steam pressure, PRS systems protect boilers, enhance process control, and contribute to overall production efficiency and sustainability.

A PRS system, or pressure reducing station, is a device that is used to reduce the pressure of steam from a boiler to a lower pressure that is required by the process equipment. PRS systems are typically made up of a pressure regulator valve, a strainer, and a pressure gauge.

A pressure reducing valve is a regulating valve that maintains the steam pressure at theoutlet at a certain fixed, prescribed level that is lower than the inlet pressure. The PRVnot only reduces the pressure but also controls the flow by load fluctuationdynamically. Therefore, using the change of state of steam caused by adiabatic steam expansion, notonly the pressure changes but the temperature, specific volume, and latent heat also change.

There are many benefits to using a PRS system, including:Increased safety: PRS systems help to reduce the risk of steam burns and other accidents by reducing the pressure of steam.Improved efficiency: PRS systems can help to improve the efficiency of steam systems by reducing the amount of energy that is wasted.Reduced maintenance costs: PRS systems can help to reduce the maintenance costs of steam systems by reducing the wear and tear on equipment.

Device specifications and installation instructions vary by device type and test. Ensure that the device you plan to use on test day meets the required specifications.

Speedtest

For example, if a steam process unit has three different operations in whichsteam is required at 5 kg/cm2 pressure, 6 kg/cm2, and 4 kg/cm2 with acapacity of 2 TPH, then in this case, instead of three different boilers, youcan choose a single boiler of 6 TPH capacity and pressure greater than 6kg/cm2.

1. Quality improved of steam: Pressure reduction is the use of adiabatic steamexpansion. Since the latent heat of steam changes as pressure changes, drynessfraction increases.For example: if the saturated steam at pressure is 10 kg/cm2 with a 95% drynessfraction is reduced to 3 kg/cm2.Enthalpy of steam at inlet of PRS = 181.2 + 0.95*481.8 = 638.91 kcal/kgAnd the dryness fraction at the outlet,= (638.91-133.4)/516.9 = 0.977= 97.7%Now we can see a 2.7% increment in the dryness fraction. which simply means lesscondensate will form inside the pipe and more steam will reach the process.

The most common problems with PRS systems are:Clogged strainers: Clogged strainers can restrict the flow of steam and reduce the efficiency of the PRS system.Leaking valves: Leaking valves can waste steam and reduce the efficiency of the PRS system.Defective controllers: Defective controllers can cause the PRS system to operate incorrectly and reduce the efficiency of the PRS system.

8615510865705

8615510865705

8615510865705

8615510865705