Troubleshooting a Leaking Temperature and Pressure ... - water heater temperature and pressure relief valve

A thermostatic mixing valve (TMV) is vital to your plumbing system. Failure to properly maintain your TMV can lead to temperature fluctuations and even scalding injuries. This article outlines tips to keep your mixing valve in top working order through regular inspection, greasing, cartridge replacement, and testing. Follow our TMV maintenance guidance for optimal performance and safety.

So, whether you’re a DIY enthusiast, a curious homeowner, or just someone interested in the mechanics of everyday life, join us as we unravel the mystery of thermostatic mixing valves and their significant role in our daily living.

Discover the importance of adjusting your TMV for safety, comfort, and energy efficiency. Get expert advice from Woolf Plumbing & Gas in Perth and ensure your hot water system performs at its peak.

These variants control the water temperature for a group of outlets nearby. They’re typically found in commercial settings like hotels or gyms, where multiple sinks or showers in a bathroom need temperature regulation.

3/4" Hose Bibb Vacuum Breaker - Piston Activated, Self-Draining ... 28 reviews ... SKU: BFPYH10NL.

By using a thermostatic mixing valve, you can ensure that the water temperature from your hot water taps remains within a safe and comfortable range plumbing system, enhancing the overall safety of the plumbing system.

Have you ever wondered how you get the perfect blend of hot and cold water every time you turn on your shower or tap? That’s all thanks to a nifty device known as a thermostatic mixing valve. Today, we’ll explo re thermostatic mixing valves, from how they work to their importance in modern homes.

Thermostatic mixing valves are critical for several reasons. First and foremost, they prevent scalding by limiting the maximum temperature of the water that comes out of your shower or tap. This is particularly important in homes with children, elderly or high-risk persons who are more susceptible to burns.

gatevalve中文

A gate valve is a control valve that either allows media to flow through unobstructed or stops the fluid flow. The main advantage of this type of valve is the straight-through unobstructed passageway, which induces minimal pressure loss over the valve. The unobstructed bore of a gate valve also allows for a pig's passage in cleaning pipe procedures, unlike butterfly valves. However, these valves are slower than quarter-turn valves and should only be used in the fully open or closed position, not to regulate the flow. Automated gate valves exist with either an electric or pneumatic actuator, but a manual gate valve is cost-effective since gate valves are typically used infrequently.

Designed for applications requiring large volumes of mixed water, these are commonly used in commercial dishwashers or industrial processes where high water flow is a crucial requirement.

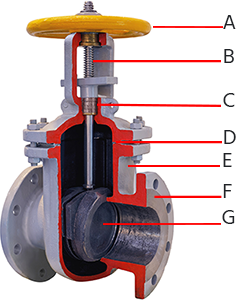

A gate valve operates similarly to other valves. To open the valve, turn the handwheel (Figure 2 labeled A), which moves the gate (Figure 2 labeled G) up or down on the stem (Figure 2 labeled B) via the threads. A gate valve requires more than one 360° turn of the handwheel to open or close the valve fully. When the gate is lifted up, it opens the inlet to the outlet allowing an unobstructed passageway for the media to flow. When the gate is lowered, it closes and blocks the media flow.

If your property has backflow preventers, they need to be inspected regularly, in most cases annually, by a licensed plumber.

Screw-in bonnets are the simplest in construction, as shown in Figure 1. They are common in small valves and provide a durable leak-proof seal.

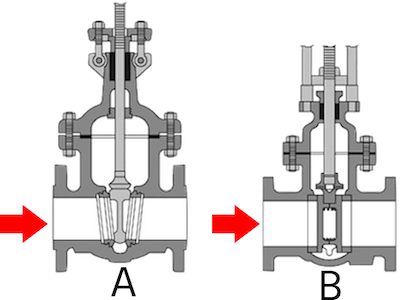

Expanding gate valves have two slab gates matched together that provide sealing through the mechanical expansion of the gate, as seen in Figure 5. When lifted, both of the slab gate's cavities allow the media to flow. The upward force on one slab and the stoppage of the second slab by a step in the valve body, allows for outward mechanical expansion for a proper seal. When closed, the slab gates block the media flow, and the downward force (stem) on one slab and upward force (step in valve body) allow for outward mechanical expansion for a proper seal.

Slurries: Gate valves are often used in applications that contain slurries as their media. This is because a gate valve has an unobstructed passageway for the fluid, so the slurry can easily pass through the valve. In addition, knife gate valves can easily cut right through the slurry to close

A gate valve works by rotating the stem (manually or with an actuator) to raise or lower a gate. The gate either allows unobstructed fluid flow or stops it.

The gate is raised and lowered by the spinning of a threaded stem (Figure 2 Labeled B). As discussed, a manual wheel or actuator spins the stem. Depending on the design, it is either considered a rising stem gate valve or a non-rising stem gate valve. So, as you spin the stem, it either raises or stays in place with the spin.

Step into the intriguing world of thermostatic mixing valves. Understand how they work, why they are critical, and how their professional maintenance can enhance your hot water system's efficiency.

Specifically designed for solar hot water systems, which can produce very high water temperatures, these valves ensure that the water delivered to the user is safe, thus preventing scalding.

On the other hand, a non-rising stem is fixed to the actuator and threaded into the gate. An indicator is often threaded onto the stem to show the valve's open or closed state. Non-rising gate valves are common in underground installations and applications with limited vertical space.

The gate valve symbol has two triangles pointing towards the center of a vertical line, as seen in Figure 3. This figure is commonly used in piping and instrumentation diagrams (P&IDs). Read our valve symbols article for more information.

Like all parts of your hot water system, thermostatic mixing valves require maintenance to maintain optimal performance. It’s best to have a qualified plumber check the valve periodically to ensure it’s functioning correctly.

The latest version of LoopCAD (OEM ... The update ensures your. Infloor radiant heating system plans have all the current information you need to get the job done ...

A knife gate valve is used for thick fluids and dry bulk solids. The gate is only one piece of metal, which is typically pointed like a knife. These valves are self-cleaning as they pass the seat rings every time they open and close.

Solenoid valve

Water gate valves: For water applications, water gate valves are commonly used since flow control is typically not done for these applications. The valve can be fully open or fully closed, allowing for proper water control.

The relationship between the gate's vertical travel and the flow rate is nonlinear for a gate valve, with the greatest changes occurring near complete closure. When used to regulate flow, the relatively high velocity of the flow at partial opening results in gate and seat wear, which, along with possible vibrations of the gate, shortens the valve's service life. Therefore, a gate valve should only be used for on/off control.

A thermostatic mixing valve works by using a temperature-sensitive element that reacts to the temperature of the water. This element expands and contracts with temperature changes, controlling the hot and cold water mix. Regardless of pressure variations in the hot and cold water supply, the TMV maintains the set temperature, ensuring the water from your hot water tap is at the correct temperature.

A thermostatic mixing valve (TMV), a tempering valve, is a sophisticated component in our plumbing systems that expertly blends hot and cold water to deliver water at a desired temperature. Acting as a regulator, the TMV adjusts the water temperature by proportionally mixing the right amount of hot water with cold water to achieve the set temperature.

A parallel slide gate valve has a flat gate and seats parallel to it. Parallel slide gate valves use line pressure and positioning to make a tight seal. Flat gates consist of two pieces and have a spring in the middle. The spring pushes the pieces towards the seats for enhanced sealing. Due to their inherent design, parallel gate valves have a safety advantage in higher-temperature applications. Furthermore, since there is no wedging action in parallel gates, closing torques are comparatively smaller, resulting in smaller, less expensive actuators or less manual effort. Due to their sliding into position, parallel gates keep dirt away from the seating surfaces.

NSF Product and Service Listings ; LF-N223-M1[8] · LF-N223-M2[8] ; 3" · 2 1/2" ; C. HOT · C. HOT ...

These valves provide an effective seal simultaneously for both upstream and downstream seats. This seal makes them ideal for applications like isolation valves in power plants, block valves in process systems, and high-temperature valves in refineries.

The valve has two main parts: the hot water inlet, which is connected to your water heater, and the cold water inlet. The heated water from the water heater and the hot and cold water mix within the valve to reach a particular temperature. Mixing hot and cold water within the valve ensures the correct temperature is maintained, preventing scalding.

Also, thermostatic mixing valves ensure a comfortable water temperature for personal hygiene. They also contribute to energy efficiency by allowing your water heater to store water at a temperature higher than what is delivered, reducing the growth of harmful bacteria like Legionella.

Thermostatic mixing valves are designed to provide a consistent and safe water temperature, even when there are fluctuations in the hot or cold water supply. This helps prevent scalding, particularly for vulnerable users such as the elderly, children, or individuals with limited mobility.

Shop for Mueller Steam Specialty products on Newegg.com. Quickly find what you are looking for with our amazing filter system. Order today for fast shipping ...

A thermostatic mixing valve works by using a temperature-sensitive element that reacts to the temperature of the water. This element expands and contracts with temperature changes, controlling the hot and cold water mix. Regardless of pressure variations in the hot and cold water supply, the TMV maintains the set temperature, ensuring the water from your hot water tap is at the correct temperature.

Common issues include a sudden change in water temperature or reduced flow. These can often be resolved by checking for debris in the valve or adjusting the temperature settings. In the event of more complex issues, it’s advisable to consult with a qualified plumber.

A gate valve is best for on/off control with minimal pressure drop when fully open. It is not suitable for throttling. In comparison, ball valves are excellent for on/off control with low-pressure drop and quick operation. They can be used for regulating flow but are not as precise as other valve types, such as needle valves. Read more in our gate valve vs. ball valve article.

These valves are widely used in various hot water systems in residential and commercial spaces. You can find them in showers, taps, and larger-scale water installations, such as boilers or water heaters. Their primary function is maintaining a stable, comfortable, and, most importantly, safe water temperature.

temperature of 110°F (43°C) for shower and bathing fixtures. Figure 1 – Typical ASSE 1069 Application. Typical MMV-M1 and LFMMV-M1 Applications. MMV-M1 or.

Also known as a TMV or tempering valve, this ingenious technology is critical in every hot water system. When you adjust the temperature on your shower dial or faucet, the tempering valves quietly work in the background to ensure the water flowing out is just the right temperature.

Finally, butterfly valves are versatile for on/off and throttling applications, with a compact design and low-pressure drop. For more information, read our article on gate valve vs. butterfly valve. Each type of valve has its own advantages and is suited for different applications based on the system's specific requirements.

These are installed near the water heater to control the temperature for an entire building or large sections. They’re typically used in large commercial or multi-unit residential buildings to maintain a consistent water temperature throughout the premises.

Wondering how often you should test your bathroom’s thermostatic mixing valve? Our guide has all the answers to put your mind at ease.

Find the Ames Fire & Waterworks 6 in. Stainless Steel Flanged 175 psi Backflow Preventer at Ferguson online for delivery or pickup at a Ferguson store near ...

For residents and businesses in Perth seeking unparalleled plumbing services, Woolf Plumbing & Gas is your premier choice. Our team of certified professionals are equipped with the knowledge and skills to handle various types of thermostatic mixing valves. Whether you need a fresh installation or regular maintenance, we’re here to serve you.

Installed directly at the point of use, such as a sink, shower, or bathtub, these valves ensure the water temperature at the specific outlet is safe and comfortable.

Viscous media: Gate valves are commonly used for viscous media like light grease and oils. The unobstructed passageway allows these media to flow easily. The valve can be pigged, a common cleaning method for these applications. In addition, valves for these applications are typically on or off for long periods of time.

Outside Screw and Yoke (OS&Y), also referred to as rising stems, are fixed to the gate. Therefore, the threads are on the actuation side. So, as the gate is raised or lowered, the stem moves with it up and down. Consequently, they have built-in visual indicators of the state of the valve and are easily lubricated. Since they have moving components, they cannot be used with bevel gears or actuators. Therefore, rising gate valves are suitable for manual actuation.

Check valve

Slab gates, also called through-conduit gate valves, are one-unit gates that include a bore-size hole. The bore is in line with the two-seat rings in the open state. This alignment creates a smooth flow with minimal turbulence. This unique design allows for minimal pressure loss in the system and is perfect for the transportation of crude oil and natural gas liquids (NGLs). The valve seats remain clean. However, the disc cavity can capture foreign material. Therefore, the cavity typically has a built-in plug for maintenance purposes of draining the accumulated foreign material.

2020929 — The most common implementation for a supply valve uses a flat washer secured with a bib screw, where the washer just closes on the opening.

What is a valve

A thorough comprehension of thermostatic mixing valves and their various types sets the foundation for a safe and efficient hot water system. However, having these devices installed, maintained, and checked by professionals is equally critical to ensure optimal operation.

A globe valve is best for precise flow control and throttling, but has a higher pressure drop. More about the differences between globe valves vs. gate valves can be found in our article.

The bonnet of a gate valve protects its internal parts by creating a leak-proof seal. Therefore, it is removable for repair or maintenance purposes. Depending on the application, gate valves can have screw-in, union, bolted, or pressure seal bonnets.

Please don’t settle for less regarding your safety and comfort. Choose Woolf Plumbing & Gas for top-tier service in Perth. For more details about our services or to schedule an appointment, reach out to us today.

Pressure seal bonnet gate valves are ideal for high-pressure applications (more than 15 MPa). They have a downward-facing cup inserted into the valve body. When internal fluid pressure increases, the cup is forced outward, improving the seal.

Butterfly valve

Condition: Brand New · Brand: Watts · Item ID: LF009M2-QT-FS · Warranty: Must be installed by a licensed technician · Warranty: To qualify for warranty coverage ...

Globe valve

Thermostatic mixing valves (TMVs) come in various types, each designed to cater to specific needs and environments. It’s crucial to understand their differences, as selecting the correct valve can impact safety and functionality. Below are some of the common types of TMVs:

As seen in Figure 2, a gate valve has seven main parts: handwheel (A), stem (B), gasket (C), bonnet (D), valve body (E), flange (F), and gate (G). A flanged gate valve or threaded gate valve is the most common connection type to connect the valve to an application. In addition, depending on the specific design and application, the handwheel, stem, bonnet, and gate can have different designs to accommodate different applications. However, the main function of the gate valve parts remains the same. Continue reading to find those sections.

Union bonnets are held in place by a union nut. The union nut sits on the lower edge of the bonnet and screws into the valve body threads. This type of design ensures that the leak-proof seal created by the nut does not deteriorate by frequent removal of the bonnet. Therefore, union bonnets are common for applications that require regular inspection or maintenance.

Each type of thermostatic mixing valve plays a unique role in ensuring water temperature safety and comfort. Knowing the differences and applications of each can help you choose the right TMV for your specific requirements and environments.

By controlling the water temperature, the TMV plays a crucial role in preventing accidental scalding—particularly in environments where vulnerable individuals, such as children or the elderly, are present. Furthermore, they ensure that the water flowing out of our taps, whether for a relaxing shower or washing dishes, is always at the perfect temperature for our needs.

These are designed with higher safety standards and usually have a broader control range. They are used in healthcare facilities like hospitals and nursing homes where accurate control of water temperature is critical to patient safety and comfort.

These are designed to function effectively in low-pressure environments. They are commonly found in gravity-fed or partially pumped water systems where maintaining a consistent water temperature can be challenging due to fluctuating water pressure.

2022721 — Expansion Tank Calculator · 1. Water Heater / Boiler / Total Water Capacity (Gallons). Gallons · 2. Initial / Supply Line Pressure. PSIG · 3. Tank ...

A wedge gate valve has a gate in the shape of a wedge that sits on two inclined seats, as seen in Figure 4, Labeled A. In addition to the primary force created by fluid pressure, a high wedging force on the seats created by the stem's tightening assists with the sealing. The wedge-shaped gate does not stick to the seat in case of high fluid differential pressure and has an increased service life due to less "rubbing" on the seats. However, wedge-shaped gate valves have an additional compression load on the seats that may result in thermal binding and restricted valve opening due to expansion.

8615510865705

8615510865705

8615510865705

8615510865705