Washing Machine Outlet Boxes & Valves - laundry valve

The control line passes the downstream pressure on the diaphragm 1 of the main valve is increased, the valve plug moves downward and the passage of flow area becomes smaller. When the torque exerted by downstream pressure on lever 2 is equal to the torque exerted by the heavy hammer on the lever, it is in a balanced state then the valve remains to open.

If the pilot self-operated pressure control valve is used for controlling downstream pressure(Figure 8 b) when the downstream pressure rises, the pressure acting under the main valve diaphragm 2 is greater than upper chamber pressure, and plug 9 moves upward to reduce the flow passage area, in this way, the downstream pressure correspond decreased. Meanwhile, the pressure acting on the pilot diaphragm 3 increases, when the force acting on the diaphragm 3 is greater than the force of the pilot set spring 7, the pilot diaphragm subassembly 6 moves to the right, and the orifice plate 4 approaches the nozzle 5. The output pressure of the pilot decreases, and the pressure on the main valve diaphragm 2 decreases accordingly, the plug 9 continues to move upwards, the flow passage area continues to decrease, and the pressure of the medium to be adjusted continues to decrease until balanced with the spring force is set by the pilot.

Step 1: Make sure the valve body is installed at the inlet of the primary heat medium with a horizontal position, and the valve stem upwards to ensure that the self-actuating actuator is positioning vertically.

Step 3: It should be installed on/off valve inlet and outlet of the self-acting temperature control valve. And install globe valve of bypass pipeline.

Regulator

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 199 2125 0077, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

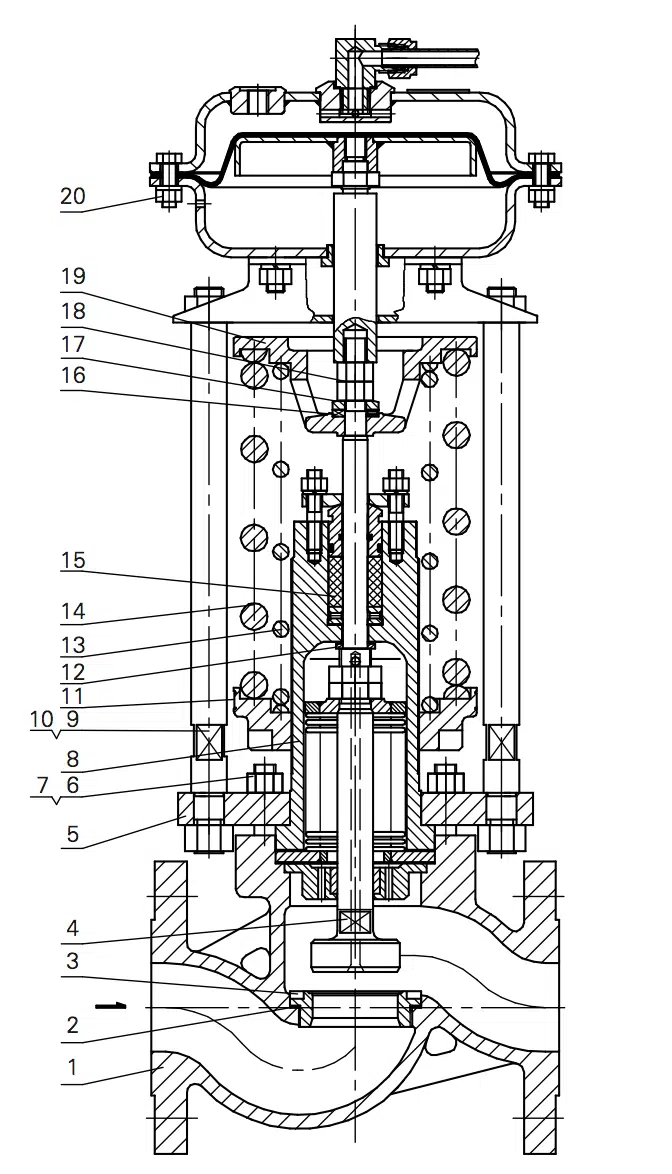

1. Body 2. Gasket 3. Seat 4. Plug 5. Grand 6. Double Stud 7. Bolts 8. Bonnet 9. Bolts 10. Yoke 11. Adjusting Plate 12. Travel Gasket 13. Inside Spring 14.Outside Spring 15. Packing 16. Thrust Needle Bearings 17. Gasket 18. Nuts 19. Spring Seat 20. Actuator

THINKTANK supply the complete self-acting temperature control valve before shipment, so the actuator has already assembly on the valve body, all you need to do is tighten the nuts between the sensor and temperature overload device.

With the RM2, you can stand behind your work and validate to customers that the coating was mixed and dispensed correctly every time.

pressure regulator中文

Dielectric Flanged Pipe Fittings feature as a companion of steel flange to bronze flange. These fittings are designed to be installed between pipe made from ...

What is avalve

The direct-acting balanced self-operated pressure control valve is the controlled inlet/outlet pressure that directly acts under the diaphragm and is balanced with the spring above or below the diaphragm. The preload of the spring can be adjusted to change the control pressure.

When controlling the downstream pressure of the self-acting control valve (figure 7 b), the signal is taken over the control line to the downstream of the valve pipeline and maintains the set pressure downstream constantly. This magnitude of set pressure depends on the weight of the heavy hammer, on the other hand, if the weight of the heavy hammer is changed, the set pressure value will be changed correspond.

In figure 1, using a temperature overload device and adjustment knob could change the volume of sensor 4 filled with the sensitive liquid to set the regulating valve at an appropriate prescribed temperature value. After the temperature in the sensor changes, the sensitive liquid volume changes, and this change is transmitted to the piston by force through the capillary tube 3, then the piston actuator 2 acts on the valve stem. When the temperature is heated, it will close the control valve. If the temperature is cooled, it will open the control valve by the spring force.

Shop for Mueller Steam Specialty Valve Strainers at Ferguson. Ferguson is the #1 US plumbing supply company and a top distributor of HVAC parts, ...

Many people may don’t familiar with the last 1960s, there is a lever and weight type direct-acting self-operated pressure regulator(figure 5), and its inherent flow characteristics you can refer to in figure 6.

If medium temperature rising up, the temperature-sensitive fluid in the sensor is heated and will expand capillary to close the valve. If medium cooled, the temperature-sensitive fluid in the sensor is contacted then makes the valve open.

2022913 — A water softener is a great addition to any home for many reasons. They are particularly useful in areas where water hardness is particularly high.

Nowadays, there are two types of self-operated pressure regulators, direct-acting self-operated pressure regulators, and pilot-operated pressure regulators.

Pressureregulator valve

As long as sensor 4 (figure 1)is inserted into the pipeline to be temperature adjusted, the change in the temperature of the medium can be felt, thereby controlling the opening of the valve. Because the temperature-sensitive fluid is fill in sensor 4, then responds to capillary tube 3.

Self-acting temperature control valves also known of self-operated temperature regulator, it doesn’t need any external power sources to regulate the temperature of process streams, tanks, and various systems. THINKTANK’s self-operated temperature regulators are often used for boiler temperature adjustment. It can maintain a linear functional relationship between temperature and valve opening.

WSSC Water delivers clean drinking water to almost 2 million people in ... Utility Navigation. News · Public Notices · Careers · Employee Portal · Sign Up / Log ...

Avoid your inquiry is delay response, please enter your WhatsApp/Wechat/Skype along with the message, so we can contact you at the very first time.

ZZC, ZZV self-operated differential (micro) pressure regulator is not needed to require external energy, and differential (micro) pressure can be adjusted in sections, ranging from 50mm.w.c to 0.1MPa. It has a wide range of uses and can be used in industrial combustion furnace systems to control the ratio of two materials, such as gas and air, to achieve ideal combustion. Used in the sealing oil system of hydrogen-cooled generator sets to control the differential pressure between the sealing oil and hydrogen to ensure reliable sealing. When the low-pressure end of the differential pressure regulator is open to the atmosphere, it is named the micro pressure regulator.

BFE-800-PC - 8" Backflow enclosure (30W X 96L X 42H) - Powder coat prime & color - Tools for industrial construction and maintenance of water systems in ...

Conversely, when the downstream pressure decreases, the pressure acting on the pilot diaphragm 3 decreases, when this pressure is less than the force of the pilot set spring, the pilot diaphragm subassembly 6 moves to the left, and the orifice plate 4 leaves nozzele5, the output pressure of the pilot increases, the valve plug 9 is opened, and the downstream pressure rises to meet set pressure value. Needle valve 1 is used to adjust the magnification, and filter 8 can filter out particles in the medium to prevent the nozzle from being blocked and losing its function.

Since the self-acting pressure control valves do not need air supply or electric power to operate, so it’s kind of the most cost-effective pressure control valves to achieve a simple process of pressure control.

Butterflyvalve

Eliminate hard water problems with our Water Softener System. Prevent scaling, soap scum, and mineral buildup while enhancing your appliances lifespan.

We will reply you within 24 hours. If for urgent case, please add WhatsApp: +86 185 1656 9221, or WeChat: +86 199 2125 0077. Or call +86 189 5813 8289 directly.

A backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow. In this situation, dirty water from ...

* Size: DN15 to DN200* Pressure Rating: PN16 to PN25, Class 150LB* Trim Type: Single-seated, double-seated, cage-guided, three ways* Applicable Medium: Hot water, Cooling water, Steam, Hot oil and etc.,* Applicable Temperature: -20℃~350℃* Overrun is typically 30°C to 50°C above the set temperature, according to the control type* Control Temperature Range: 0~70℃/50~120℃/100~170℃/150~220℃/200~270℃* Environment Temperature: -40℃~+80℃* Adjustment Accuracy: ±5%* Capillary Tube: 3.5 to 4.5m, or the length which the customer required.* Balance Component: Bellows, Spring

Joined WattFit at the beginning of the year and it has been the best thing that I have ever done. I love the Group Training Sessions – working out with fun, ...

When controlling the upstream pressure of the self-acting control valve (figure 7 a), the signal is taken over the control line to the upstream of the valve pipeline and maintains the set pressure upstream constantly. The control line passes the upstream pressure on the diaphragm 1 of the main valve is increased, the valve plug moves downward and the passage of flow area becomes larger, then the inlet pressure corresponds decreases, it will make the lever and weight 3 force plug moves upward, the passage of flow area becomes smaller until the upstream pressure meets the set pressure.

Step 2: At the inlet of the self-acting temperature control valve, it needs to install a strainer, and the required filter mesh corresponds with the medium.

1. Medium Flow Rate(Q) (T/H)2. Inlet Pressure P1 (Mpa)3. Outlet Pressure P2 (Mpa)4. Medium Name5. Temperature of Medium (℃)6. Other Requirement

Emerson automation solutions regulators and relief valves

As a general rule, the control accuracy of the direct-acting self-operated pressure control valve is not high. A pilot valve design is mainly to increase the control accuracy. The control accuracy can be twice as high as the general direct operation pressure regulating valve, and the adjustment of differential pressure ratio is large (such as 0.8MPa upstream, 0.001MPa downstream), Especially suitable for micro pressure gas control. THINKTANK’s gas regulators serve for many projects of gas sealing system and safety protection system of the storage tank. Such as nitrogen sealing of storage tanks.

Springer Industrial started building finishing production lines more than thirty years ago, and while the technology included in those lines has changed significantly since then, the ways that we judge a successful installation have not.

Springer Industrial Contact Us Toll Free: 800-388-3144 AR, AZ, CA, CO, ID, LA, MT, NM, NV, OK, TX, UT, WY, Northern Mexico

Self acting pressure control valves used to keep the adjustable set-point pressure within certain range in tanks or processes. It doesn’t request any auxiliary energy to operate valves but by the medium energy itself.

A pilot-operated self-operated pressure control valve also known as a nitrogen regulating valve, this valve does not require auxiliary energy, uses the energy of the process medium (gas) as power. The pilot valve amplifies the feedback signal and then through the actuator, drives the movement of the main valve plug to the opening valve.

Fishervalve

The temperature overload device sometimes also includes pressure gauge 5, and we can read the temperature data for temperature-sensitive liquid.

According to the action type, there are inlet/upstream pressure control type and outlet/downstream pressure control type self-acting pressure regulating valve.

This lever and weight type direct-acting self-operated pressure control valve are barely not used for modern industry, but still wort at some old equipment.

Watts® HeatH2O Hot Water Recirculation System. Model Number: 0955805 Menards ® SKU: 6910010 ... The recirculating pump uses a heavy-duty stainless steel pump head ...

Based on the difference of any working condition, the direct-acting ZZY series self-operated pressure regulator can be classified into 3 types according to its inside part: ZZYP (single-seat self-operated pressure regulator); ZZYM (cage type self-operated pressure regulator); ZZYN (double seat self-operated pressure regulator), customers can also choose the type by the local actual working condition(differential pressure, temperature, medium state) or leakage requirement. There are 3 different bonnet types according to the working condition: standard (normal condition), long neck type(big range for pressure adjusting), heat radiation type(temperature 350~550°C). The ZZY series Self-operated pressure regulator applies with the quick opening flow characteristic, which is quickly acted and highly accurate adjusted (error≤10%), so it can be widely used in many fields like petroleum, chemical, electricity, metallurgy, food, textile, machinery, and civilian building and so on to reduce/release or stabilize the pressure of the gas, steam, and liquid and so on.

THINKTANK Since 2005, offers over a decade of expertise in designing, manufacturing, and globally selling top-quality control valves, ensuring superior fluid control solutions.

PRVvalve

1. Medium Flow Rate(Q) (T/H)2. Inlet Pressure P1 (Mpa)3. Outlet Pressure P2 (Mpa)4. Medium Name5. Temperature of Medium (℃)6. Other Requirement

Please refer to figure 2 for installation layout, and kindly noted that the optimum working range of the inlet stream is around 3.0 to 7.0 bar. Any information just feel free to contact us representative marketing at cncontrolvalve.com

FloodStop Washing Machine Valve Shutoff Kit 3/4″ Point-of-Use appliance based shutoff valves in dual configuration for washing machine leak protection.

As a responsible valve company, we have participated in many self-regulating valve projects. We believe that our rich experience and reasonable prices can help you open up the market.

The sensor is inserted around the outlet of the heat exchanger or outlet pipe of water. Be careful of the valve stem and capillary tube during installation. Drilling a hole in the pipeline to insert the sensor, then welding without any leakage from this connect part.

As a responsible valve company, we have participated in many self-regulating valve projects. We believe that our rich experience and reasonable prices can help you open up the market.

A self-acting control valve is also known as a self-operated pressure regulator, which doesn’t need any auxiliary power to drive the valve, the self-acting control valve through the medium energy to operate the valve itself, that’s why it is called self-acting or self-operated. A self-operated control valve can realize the adjustment of temperature, pressure, differential pressure, flow rate, and other parameters. It has the characteristics of simple structure, low price, reliable action, and so on. It is suitable for occasions where flow rate changes are small, adjustment accuracy is not high, or instrument air/power supply is difficult.

The hot water or steam enters the heat exchanger, and the sensor of self-acting temperature control valve to sense the temperature of the outlet of the heat exchanger, if a temperature-sensitive fluid is heated, it will expand to the closing valve. If it is cooled, it will contract to open the valve.

8615510865705

8615510865705

8615510865705

8615510865705