Water Heater Pressure Relief Valve : 5 Things You Should ... - temp pressure relief valve for water heater

febco765-1 parts

Thank you for your interest in contacting us. We value your feedback and inquiries. Please feel free to reach out to us using the contact information below: WORK Learn More →

febco 765repair kit 3/4

Therefore, the velocity v is equal to 0.408 times the gallon flow rate per second, and the pipe diameter is divided by D in inches square.

Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

febco 7653/4

Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

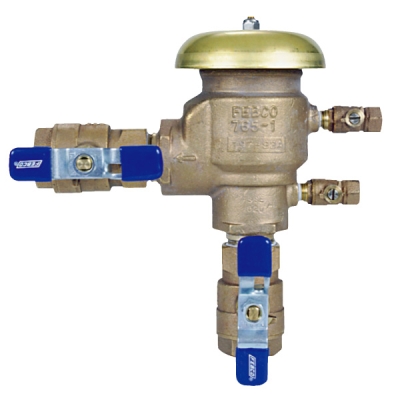

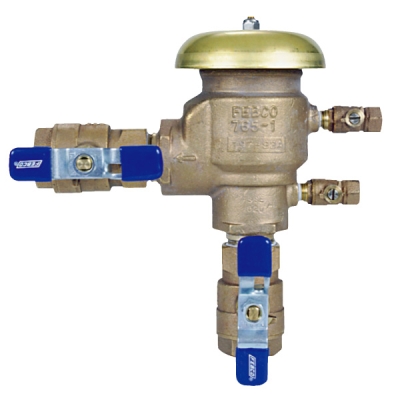

OperationThe Febco 765 PVB is designed to be installed to provide protection against backsiphonage of toxic or non-toxic liquids. It consists of a spring loaded check valve which closes tightly when the pressure in the assembly drops below 1 PSI or when zero flow occurs, plus, an air relief valve that opens to break a siphon when the pressure in the assembly drops to 1 PSI. Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

febco 7651 1/2 repair kit

Alternatively, if the flow rate is measured in gallons per minute, the following formula can be used to calculate water velocity.

The above formula works best when the flow rate is measured in the form of a standard length unit cubic form. But things are a little tricky when the flow rate is measured in gallons per minute or liters per minute.

Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Febco 765parts diagram

So, the velocity of water inside a 1.5″ pipe with a flow rate of 20 gallons per minute is equal to 3.62 ft/s.

Fluid flow velocity in water systems should not exceed certain limits so as to avoid noise and damaging breakage of pipes and fittings. The table below can be used as a guide for maximum velocities:

Febco 765leaking

Febco 765 PVBrepair Kit

Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

If you have any questions about our cancellation and refund policy, please contact us at [9840140396] or email us at contact@lceted.com.Learn More →

Acceptance of Terms By accessing and using the website at www.lceted.com, you agree to be bound by these Terms of Service, all applicable laws, and regulations. If you do not agree with any part of these terms, you may not access the site. These terms apply to all visitors, users, and others who access or use the site.Learn More →

Febco 765Manual

The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Water velocity is a measure of the speed of water flowing through a closed pipe system. Water velocity can be determined using a simple formula:

THIS PRIVACY POLICY DESCRIBES OUR POLICIES AND PROCEDURES ON THE COLLECTION, USE AND DISCLOSURE OF YOUR INFORMATION WHEN YOU USE THE SERVICE AND TELLS YOU ABOUT YOUR PRIVACY RIGHTS AND HOW THE LAW PROTECTS YOU.Learn More →

8615510865705

8615510865705

8615510865705

8615510865705