Water Pressure Reducing Valve - water pressure prv

AMTROLExpansion Tank SizingChart

Bonnet Assembly Repair Kit Fits for Watts 800M4-B LF800M4/800M4 1 Inch Pressure Vacuum Breaker Backflow Preventer ... watts backflow preventer parts · watts 009 ...

What sizeexpansion tankdo i needfora 100 Gallonwater heater

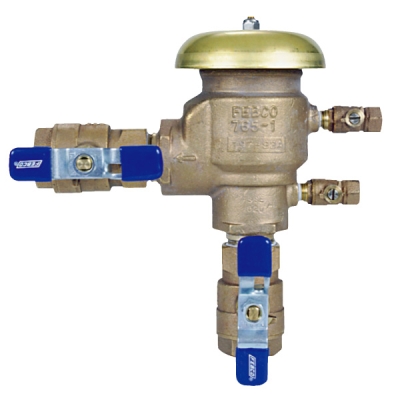

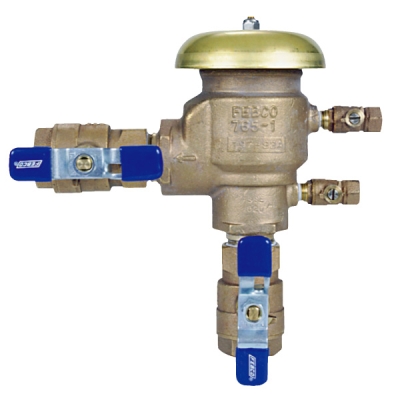

Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

OperationThe Febco 765 PVB is designed to be installed to provide protection against backsiphonage of toxic or non-toxic liquids. It consists of a spring loaded check valve which closes tightly when the pressure in the assembly drops below 1 PSI or when zero flow occurs, plus, an air relief valve that opens to break a siphon when the pressure in the assembly drops to 1 PSI. Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The valve should be connected to a discharge pipe (also called a drain line) that runs down the length of the water heater tank. This pipe is responsible for ...

Using SharkBite 3/4-inch MNPT x 3/4-inch Push-to-Connect fittings, installation of the FEBCO 765 Pressure Vacuum Breaker couldn't have been simpler.

Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

What sizeexpansion tankdo I needfor80 gallonwater heater

Reference the Manufacturer IOM for instructions on properly charging the thermal expansion tank as well as troubleshooting recommendations.

Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Note: Watts has rebranded SeaTech to Watts AquaLock. This rebrand does not affect the part numbers. However, during the transition the product and packaging ...

Steam Safety Valves. Pressure relief valves are designed for steam applications and protecting critical equipment, such as boilers, utility steam lines, or ...

Acquaer 115V 3-Speed Hot Water Recirculating Pump, 11 GPM Manual Ⅱ. Sale price$65.99 Regular price (/). Sold out ...

The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Expansion tank sizingby btu

Expansion tank sizingcalculator

In all cases shown above, a missed selection will cause the pressure in the system to be higher than design. If that pressure gets close to the pressure relief setting, the relief valve will open. We never want to use a safety device as a control mechanism. That is the job of the thermal expansion tank.

Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

12 Sept 2023 — How long does the RO membrane last? ... Reverse osmosis (RO) membrane's longevity typically spans two and five years, making it a durable ...

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The Apollo 4ALF-109-03 - 2-1/2" is at ValveMan.com. Shop the 2-1/2 Apollo 4ALF-109-03 stainless steel backflow preventer with double check valve assembly ...

We can see that missing the volume has a huge effect on the tank size, so safety factors should be applied to the volume. Your choice of safety depends on the reliability of your calculations.

30 May 2023 — The membrane manufacturers will usually prorate their membrane warranty over three years, although it is rare for a membrane failure to occur ...

Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Hydronicexpansion tank sizingcalculator

One final note about thermal expansion tanks. As mentioned above, the result of any undersizing is increased pressure. If the pressure is getting so high that the relief valve is opening, there are two places to look first.

Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Choose from our selection of adjustable pressure relief valves, including pressure-relief valves, back-pressure-regulating valves, and more.

Expansion tank sizingrule of thumb

Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

AMTROLexpansion tank Sizingpdf

You can visit last week’s Monday Morning Minute, Thermal Expansion Tank Sizing: Bell & Gossett Systemwize, for more information on this formula.

The purpose of the thermal expansion tank is to limit the pressure rise when the volume of water in the hot water system is heated from the initial temperature to the design temperature when there is no draw on the system. Last week we introduced the formula:

Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

In the last R. L. Deppmann Monday Morning Minutes we used the Bell & Gossett Systemwize selection program to size and select a water heater thermal expansion tank. Safety factor when sizing is always on the mind of the engineer or plumbing contractor. Where do I apply safety factors and what happens if the tank is undersized? Today we address these concerns.

8615510865705

8615510865705

8615510865705

8615510865705