Watts 2 IN LFM115-74 150 ACV Pressure Reducing Control ... - lfm115

Thermodynamic Thermodynamic traps operate based on a pressure difference on either side of a disk (sometimes called disk traps). The disk is free to move in the vertical direction. Steam from the jacketing system pushes upward on the disk through an orifice. Steam above the disk pushes downward on the disk across the entire disk surface area. When the steam above the disk condenses, system pressure lifts the disk, allowing steam and condensate flow out of the trap. When the disk is up, and all of the condensate has exited the trap, fresh steam re-enters the chamber above the disk and pushes the disk down. In essence, thermodynamic traps operate based on heat loss to ambient rather than responding to the presence of condensate in the steam jacketing. Thermodynamic traps are very sensitive to the pressure in the condensate return system. If the condensate return pressure exceeds 50-80% of the steam pressure just upstream of the trap, the disk will begin to rapid cycle then fail open, and the jacketing will not operate as designed. The condensate return pressure has to be very carefully considered for successful system operation with thermodynamic traps.

Regardless of the type of steam trap selected, a reliable and sustainable maintenance plan is recommended. The type of steam trap utilized can influence the type of maintenance and schedule as some are more robust and reliable than others. All traps eventually fail, and trap surveys commonly report that a third of a plants’ trap population does not function properly.

Spirax Sarco

Mechanical Mechanical traps sense the difference in density between steam and condensate. The two main types of mechanical traps are: (1) inverted bucket and (2) float/float & thermostatic. Inverted bucket traps feature an upside-down bucket inside the trap housing. The bucket is free to move in the vertical direction. When steam is in the trap, it lifts the bucket which causes the orifice to close. When the steam in the trap condenses and/or when condensate enters the trap, the bucket falls, the orifice opens, and condensate discharges. Most inverted bucket traps incorporate a small bleed hole to allow any air in the system to escape. Inverted bucket traps are the most robust choice for steam jacketed systems as they require no special considerations. Float traps feature a ball float inside the trap housing. When steam or air is in the trap, the ball rests on the trap floor. When condensate enters the trap, the ball floats on the condensate and rises, the orifice opens, and condensate discharges. The orifice is located in the liquid level, requiring additional air purging capability to avoid air lock. Provided some form of continual air purging is incorporated in the trap design, float traps can function well in a steam jacketed system.

Steamtrap types

3. Accommodate condensate return pressure. A certain amount of system pressure is required downstream of the trap to return the condensate to the boiler. Some traps will not function if the condensate return pressure is high relative to the steam pressure.

Condensate Removal The primary purpose of a steam trap is to remove condensate (condensed steam) from a steam heating system while “trapping” steam in the system. Constant condensate removal is essential to the successful operation of the heating system. There are many different types of steam traps, with many different features, available in the market, but not all steam traps perform well in all applications. For successful operation, the steam trap must meet three key requirements:

Steam

Copyright © 2022, StrongBox. StrongBox is a subsidiary of MUM Industries. | Trademark Information | Privacy Policy | Terms & Conditions

2. Continuously purge entrained air/non-condensables. At start-up, the jacketing is full of air. Air can also enter the system during normal operation. Air works as an insulator and must be removed from the system so the steam can contact all heat transfer surfaces and to avoid air/vapor lock. Some traps easily and continuously vent, but others are susceptible to “air lock” which prevents the condensate from being removed and negatively impacts heat transfer.

Steamtrap working principle

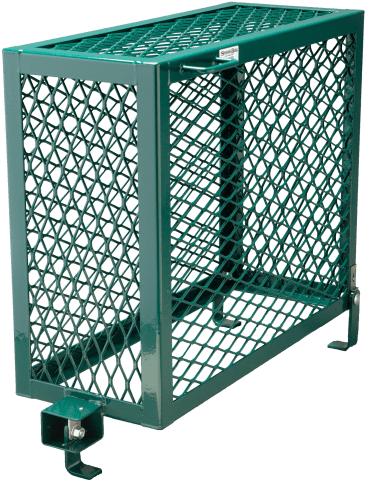

This backflow cage is a vandal and weather resistant enclosure formed from expanded metal. The cage is powder coated with a polyester TGIC coating having a minimum thickness of 2.5 mils. The cage includes a bracket-mounted hinge that is carriage bolted on one end to allow for removal of the backboard, with and a pad-lockable tab on the other end. The mounting brackets at the base of the cage are to be submerged into concrete a minimum of 2 inches, positioning the enclosure 1-1/2 inches above the surface for drainage purposes. Handles are attached to the sides to allow for raising and lowering of the cage.

Thermostatic Thermostatic traps sense the temperature difference between steam and subcooled condensate. These traps feature either a bi-metallic strip or a gas-filled or liquid charged diaphragm or bellows. When the strip/diaphragm/bellows is hot, it expands and closes off the valve/orifice. When the strip/diaphragm cools to a pre-designed temperature, it contracts enough to open the orifice and allow condensate to exit the trap. For a thermostatic trap to open, condensate must dwell in the trap long enough for its temperature to drop well below the steam temperature. To achieve the necessary subcooling, condensate must back up in the piping/tubing upstream of the trap, and this can cause condensate to back up inside the jacketing. For this reason, thermostatic traps are not recommended for steam jacketing systems.

1. Keep the jacketing clear of condensate. Some traps require significant condensate cooling before allowing the condensate to exit the system. This can result in condensate build-up in the jacketing system and affect the system’s ability to transfer heat to the process.

Types of Steam Traps Condensate is physically different from steam in two regards: (1) it has a higher density, and (2) it can be significantly colder. A steam trap is a thermo-mechanical device that responds to these property differences to control the opening and closing of an orifice which allows condensate to escape while retaining the steam. There are three distinct categories of steam traps: Mechanical, Thermodynamic, and Thermostatic.

8615510865705

8615510865705

8615510865705

8615510865705