Watts 8-1/2" x 5-1/4" Boiler Feed Valve w/Backflow ... - b911s-m3

How often to change reverse osmosis membraneaquarium

Romembranefilter

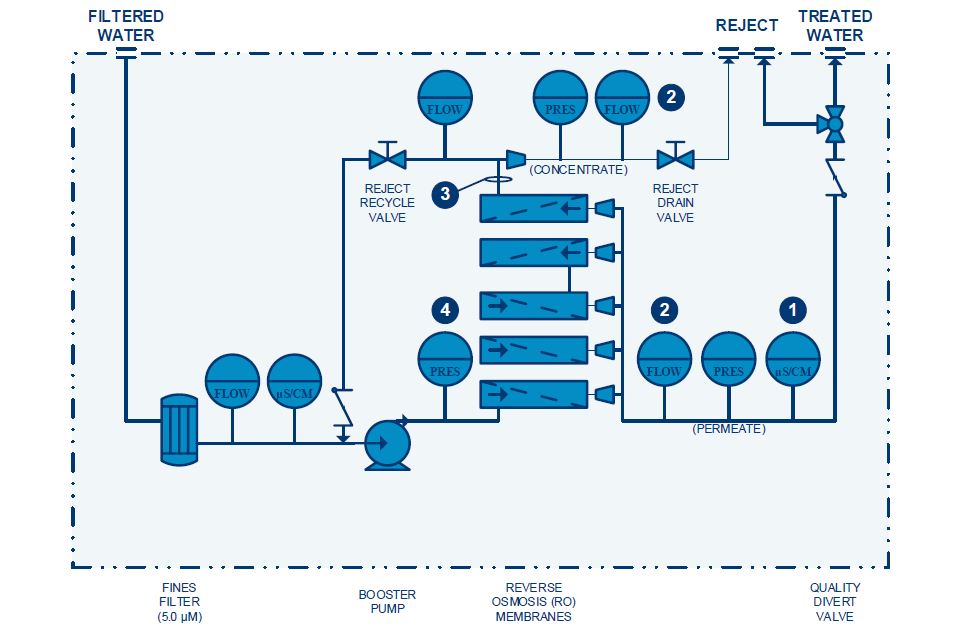

1) RO Permeate Quality: Typically 1-3% of the feedwater TDS or Conductivity but is normally affected by temperature and presence of dissolved gasses. An increase in salt passage (inversely, decrease in salt rejection) may indicate membrane or o-ring damage. 2) RO Permeate Recovery Rate: Typically 75% for commercial/industrial ROs and is dictated by the pressure vessel array, membrane type, and feedwater quality. Recovery is set by adjusting the pump driving pressure and balancing the reject valves. Adjustments are normally required due to temperature changes but can be affected by fouling or scale formation on the membranes. Too much recovery accelerates membrane fouling and scale formation. 3) RO Reject Flow Rate: Typically 25 GPM per final stage 8” Pressure Vessel. Too little flow accelerates membrane fouling. System recovery can be increased by diverting a portion of this flow back to the front of the unit with a tradeoff in product quality and increased scale formation risk (due to salt concentration cycling within the RO). 4) RO Normalized Driving Pressure: Used to determine when to clean or replace RO membrane elements. Normalization calculations are used to offset the effects of temperature and osmotic back pressure when evaluating RO performance data. Baseline readings are taken with new or freshly cleaned elements and a 10-15% increase in driving pressure from fouling, biofilm, or scale formation is often used to trigger a cleaning procedure.

Like everything else associated with your water heater, this valve is subjected to the long-term spread of corrosion. This can cause the valve to no longer emit water or steam, or to spring a leak. If youâre noticing dripping water coming from the T&P valve, you have a problem that goes far beyond the small pool of water on the floor. A leaking valve indicates a pressure problem, which means your water heater is going to struggle to keep its water at the right temperature.

As weâll explore in the sections below, T&P valve problems can pose a risk to both your water heater and your home. If you think you might need T&P valve replacement, you need to call our plumbers right away. You donât want to procrastinate on water heater problems. At best, your water heater could stop working, leaving you and your family without hot water. At worst, your water heater tank could fail, potentially flooding your home. The stakes here are real.

How often to change reverse osmosis membranein water

Your relief valve should last as long as your water heater does. However, T&P valves are known to encounter issues that cause them to malfunction. A safely functioning valve relies on its ability to both open (when it detects high pressure) and close (when it detects that the pressure issue has been resolved). If your valve is stuck and canât do one or both of these things, it needs to be replaced as soon as possible.

There are a variety of environments and variables that can affect the rate that your membranes degrade. Membranes that need to be cleaned or replaced will let you know in the form of performance data when you see that your energy consumption has increased or if you notice higher pressures are required to make the same amount of water. Some changes, like decreased salt rejection, are symptoms of permanent damage like chemical attack and cannot be recovered with cleaning. While RO systems can be lower energy consumers than other purification methods like distillation, you can still see increased costs by running membranes that aren’t performing as they should. Keep in mind that if you decide not to change your membranes for an extended amount of time, you risk the service life of every other component and downstream equipment in your system.

ROMembraneReplacement cost

Most homeowners arenât all that familiar with the detailed inner workings of their home appliances. For the most part, your oven, dishwasher, dryer and other appliances all just work. The same thing goes for your water heater. Often tucked away in a garage, closet, or basement, itâs easy to forget about the water heaterâdespite how important it is to your familyâs daily routine.

Well, it depends… Sorry, but the recovery percentage, feedwater quality, pretreatment effectiveness, maintenance regularity, applications requirement, and a whole host of other factors play into determining the cleaning or replacement interval for RO membranes. You need to be very in tune with your system and understand how it performs overall and how seasonal fluctuations in feedwater like temperature and quality can impact performance. In general, systems with higher recovery or systems that treat dirtier water see the most frequent cleanings or replacements. Certain industries follow rough guidelines with most pharmaceutical applications cleaning membranes at least every year and replacing on a set interval every 3-5 years, beverage manufacturers cleaning quarterly and running to fail within 3-7 years, and municipal and seawater replacing annually. These numbers can vary, but they guide when you need to analyze your system performance to see if replacement makes sense.

How often to change reverse osmosisfilters reddit

Luckily, testing your valve doesnât require increasing the temperature and pressure to unsafe levels. Instead, youâll need to position a bucket under the discharge pipe. Carefully pull the valve open. If water comes out of the discharge tube and into your bucket, thatâs a good thing. Release hold of the valve. Its lever should âsnapâ back into place and water should stop coming from the tube. This, too, is an indication that your relief valve is working as it should.

This continues until enough pressure is released for the valve to close. Plumbers refer to this as âblowdown.â While youâll have some water on your garage or closet floor that youâll need to clean up, itâs far better than the alternative. Without a functioning valve, the pressure in the water heater can climb to dangerous levels. Eventually, the tank may âburst,â causing water to flood out of the appliance and into your home.

How totell if ROmembraneis bad

Itâs a good idea to routinely test your pressure-relief valve. As weâll explain in a section below, T&P valves can malfunction or become âstuckâ after years of no usage. You should ensure yours is working so that it can continue to protect your water heater and your home. Most homeowners pair this with an annual water heater flushâthis makes it easier to remember this important task.

If your pressure-relief valve is either stuck or leaking, you need to call the plumbers here at Wagner. T&P valves were not designed to be replaced by homeowners. In fact, most manufacturers designed these valves to be hard to remove, so that this critical safety feature couldnât be intentionally disabled. Youâll need our plumbers, with their tools and expertise, to handle the job.

If thereâs one piece of your water heater that you should know, however, itâs the pressure-relief valve. This water heater safety valve is crucial to the safe operation of your water heater. In this article, weâll go through what this valve is, how exactly it works, and what you need to do when something goes wrong with it.

Your water heater pressure-relief valveâalso known as a T&P valveâis a critically important safety feature of your water heater. In short, this valve helps alleviate excess pressure from within your water heater, helping prevent potential tank bursts and leaks. A T&P valve can be found on every standard water heater and on some tankless water heaters.

Changing RO membrane elements is a simple task that is labor-intensive, includes repetitive steps that can be overlooked, and sometimes requires unusual handling when using specialized membranes. Therefore, Aqua-Chem recommends a professional field service technician performs or leads the task to ensure no mistakes are made, especially if membrane replacement is an infrequent activity for the system owner. Aqua-Chem field technicians are trained on all makes and models of reverse osmosis equipment and have many years of experience to ensure proper installation and peak performance.

ROMembraneprice

ROmembranelife calculation

This is where the water heater pressure-relief valve comes into play. When the pressure reaches a certain point, it forces the valve open. Your relief valve is connected to a long discharge tube. When the valve opens up, both steam and hot water are forced out of this tube and onto the ground around your water heater.

Watch this video to see what a T&P valve looks like, how it opens to release pressure from the water heater, and what our plumbers need to do in order to replace a faulty valve.

Your water heater warms and then stores heated water inside of its metal tank. Most water heaters store water at between 120 and 140 degreesâthis is typically warmer than whatâs needed at the tap, but not cool enough to become cold by the time it reaches your shower heads and faucets. At this temperature, the PSI (pounds per square inch) pressure inside your water heater is well within the parameters your water heater was designed to handle.

Homeowners here in Albuquerque know and trust our plumbers to do the job right. Weâre proud to be your homeâs best friend. Generations of homeowners have turned to our team to help them with their plumbing and water heater problems.

Problems typically arise when things heat up. Whether due to a change in the temperature setting or due to a malfunction, higher water temperatures mean more pressure inside the tank shell. At about 200 degrees, the water heater is starting to feel the stress of a higher PSI.

There are a variety of environments and variables that can affect the rate that your membranes degrade. Membranes that need to be cleaned or replaced will let you know in the form of performance data when you see that your energy consumption has increased or if you notice higher pressures are required to make the same amount of water. Some changes, like decreased salt rejection, are symptoms of permanent damage like chemical attack and cannot be recovered with cleaning. While RO systems can be lower energy consumers than other purification methods like distillation, you can still see increased costs by running membranes that aren’t performing as they should. Keep in mind that if you decide not to change your membranes for an extended amount of time, you risk the service life of every other component and downstream equipment in your system.

Cleaning your membranes is a great way to extend their service life. Membranes that are cleaned and well maintained will save you money in reduced energy costs, less waste, and better product quality. If you don’t have a membrane cleaning program in place, contact your service provider to get a longer service life out of your membranes. Different cleaning procedures are used to remove different types of contamination, and elements can be cleaned in place (CIP) with the right equipment or removed and cleaned off-site. For example, acids are often used to dissolve hardness scaling, bases (caustic) are often used to remove organic fouling, surfactants and chelating agents are used to remove fouling or heavy metals. In addition, there are many suppliers of proprietary cleaning solutions that address multiple contaminants simultaneously. Keep in mind that it’s not always possible to gain back all the baseline performance of the element, and aggressive cleaning can damage the membrane surface. Therefore, the best strategy for scale and fouling is to prevent it from forming in the first place.

Spiral wound membrane elements are the heart of your Reverse Osmosis (RO) filtration system. RO membranes feature a semi-permeable surface that allows water to pass through while selectively rejecting most contaminants from the feed water source. The elements can filter virtually all suspended and dissolved contaminants and quickly plug when used for “direct filtration.” Hence, a “cross-flow” configuration is typical where a portion of water is sent to drain to limit fouling or scale buildup. Residential household, wastewater, and seawater RO systems will typically purify 25-50% of their feed water supply. Commercial and industrial RO systems average 75% recovery but operate anywhere between 65-95% depending on feedwater quality, selected pretreatment equipment, and the number of membranes used. The waste water stream often referred to as “brine” or “reject,” consists of concentrated salts and organics and is usually discharged directly to the sewer. RO membrane performance is sensitive to temperature and feedwater quality changes and fouling or chemical attacks will gradually impact the quality and quantity of water produced. So, what do you need to know to ensure your RO system is running effectively and efficiently? First, let’s explore some of the common questions you might have about Reverse Osmosis Membranes.

8615510865705

8615510865705

8615510865705

8615510865705