Watts 8142406 - hy-420 lf repair kit

FEBCO

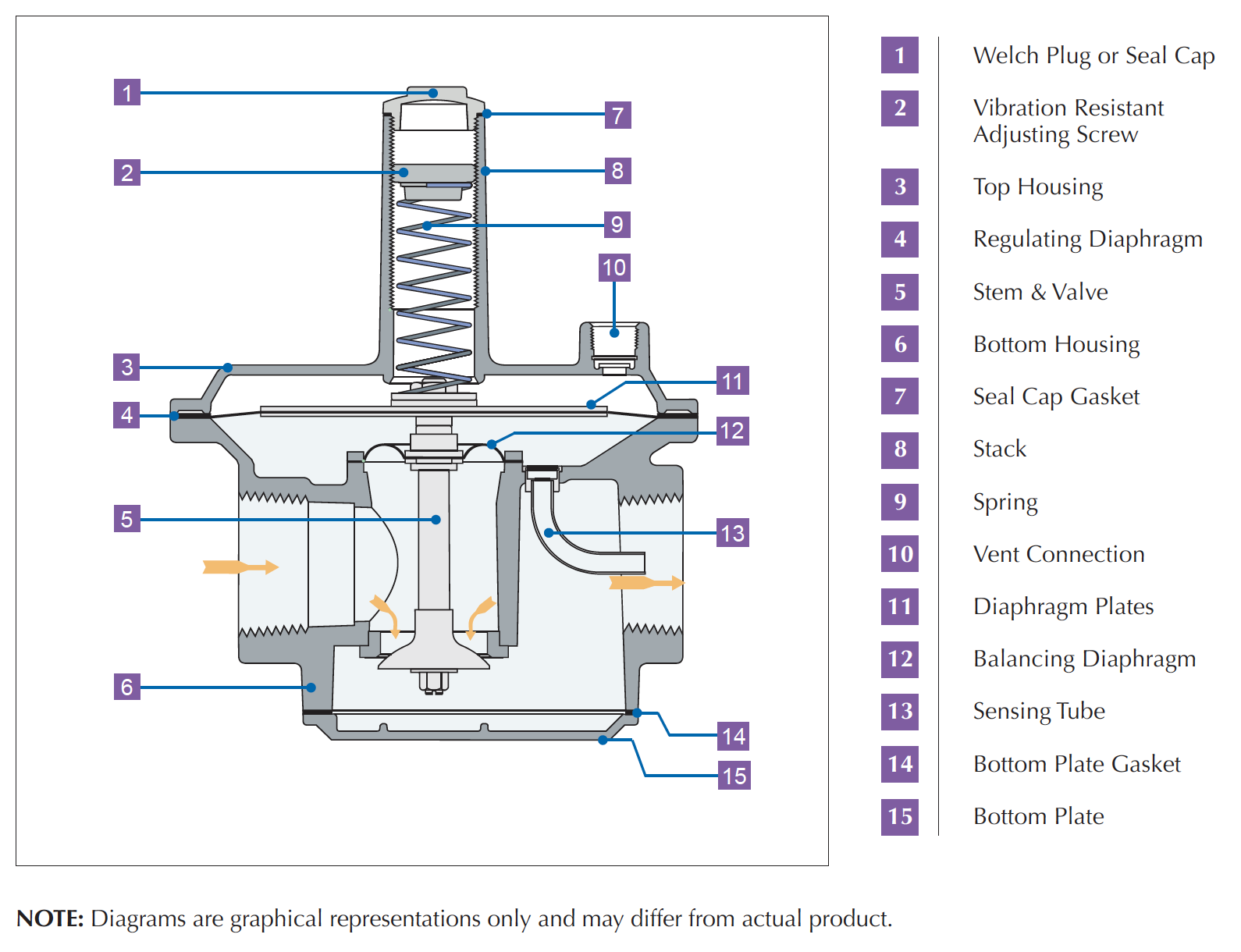

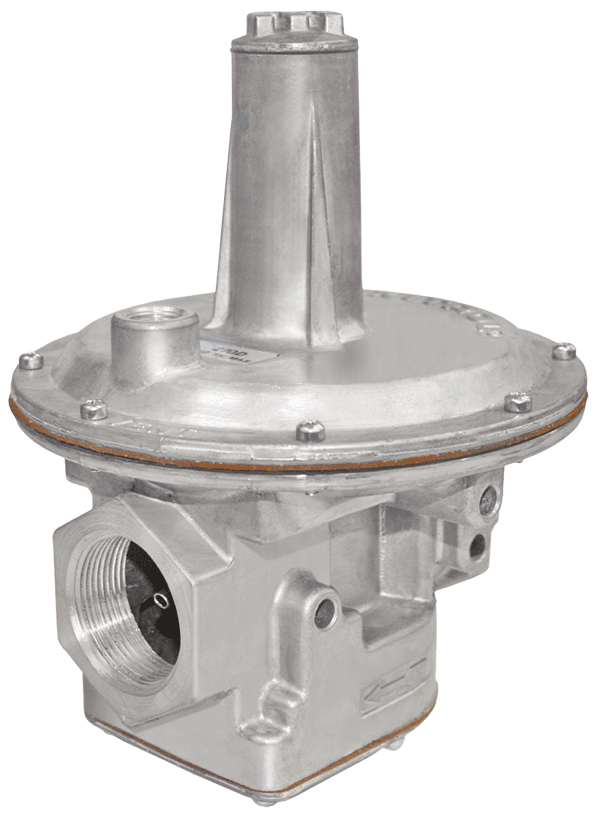

210 Series balanced valve design is a lockup-type regulator. The balanced valve design makes it possible to maintain steady outlet pressure control with widely varying inlet pressures. The 210 series provides precise regulation over a wide range of pressures and flow rates. Applications include gas-fired boilers, steam generators, industrial furnaces and ovens. Remote sensing option is available on 210D, E, and G models.

Backwater valve

Suitable for natural, manufactured, mixed gases, liquefied petroleum gases, LP gas-air mixtures, and gases of DIN EN 437 gas family 1, 2, and 3

backflowpreventer中文

TitleDescriptionVersionDownload R Balanced Valve Design (NA) Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt)🇺🇸 North America, Imperial Units; GPR_MS_EN_09.2024 (R) DownloadPreview 210 Balanced Valve Design (NA) Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt)🇺🇸 North America, Imperial Units; GPR_MS_EN_09.2024 (210) DownloadPreview R/210 Balanced Valve Design (EU/UK) Catalog; Lockup type regulator. Maintains steady outlet pressure control with widely varying pressures. (excerpt)🇬🇧 EU/UK, Metric Units; GDR.GF-LT-EN_09.2022 (R/210) DownloadPreview Gas Pressure Regulator and Modulator Catalog (NA) Catalog; Gas Pressure Regulators and Modulators (full catalog)🇺🇸 North America, Imperial Units; GPR_MS_EN_09.2024 DownloadPreview Gas Pressure Regulators and Filters Catalog (EU/UK) Catalog; Gas Pressure Regulators and Filters (full catalog)🇬🇧 EU/UK, Metric Units; GDR.GF-LT-EN_09.2022 DownloadPreview

The term "Cross-Connection Control" is essentially is referring to backflow prevention. The definition of a Cross Connection is "A cross connection is the actual or potential connection between a non-potable substance or source." Local authorities will dictate what types of backflow preventers may not be used depending on the backflow risk and health hazard. Sewer, irrigation, wastewater and residential are the main areas. There are two types of backflow, the first is back pressure where the pressure in the downstream piping is greater than the supply pressure, this is caused by a pump or elevation of water in a high rise building, the other type of backflow is back siphonage which is caused by sub-atmospheric pressure in the water system piping.

Various types of backflow preventers exist for different applications and health hazard conditions, check state and other local administrative codes or other regulation on the correct backflow to use. The following backflow preventer types are available in all sizes:

WattsBackflow preventer

Suitable for natural, manufactured, mixed gases, liquefied petroleum gases, LP gas-air mixtures, and gases of DIN EN 437 gas family 1, 2, and 3

Backflow is the undesirable reversal in the flow of water from a real or potential source of contamination back to the potable (or clean) water supply. Consider having a garden hose in a bucket of soapy water at your home, and having backflow event occur causing that soapy water to "backflow" into the drinking water portion of your home. Various types of backflow preventers exist for different applications and health hazard conditions, check state and other local administrative codes or other regulation on the correct backflow to use. The most common are reduced pressure backflow preventer and double check backflow preventer valves. Backflow preventers are primarily used in sewer, wastewater, residential backflow preventer, sprinkler and irrigation backflow applications.

Check valve

Dual Check Valve - Model GF8080, GF8080E - The Dual Check Valve or double backflow prevention valve is basically a stripped down Double Check Valve without shut off valves and test cocks. They are non-testable and are typically used by water companies and installed after a water meter to prevent the meter from running backwards and low protection against backflow. This piece of equipment is the center of controversy with many backflow authorities and should never be confused with Double Check Valves. Check with local authorities for required installation, as most do not recognize these as backflow prevention devices.

Atmospheric Vacuum Breaker - Model GFAVB - The atmospheric vacuum breaker is one of the least expensive backflow prevention assembly. The GFAVB is a non-testable unit and are good for back siphonage only for non-health hazard or health hazard conditions. They must be installed downstream from any shut off valves and cannot be under pressure for more than 12 hours. If an GFAVB is used backflow prevention on a irrigation system you must install one GFAVB after every valve for each zone in the system. It must also be installed at least 6 inches (150 mm) higher than the highest outlet in the system (some GFAVB manufacturers, and some local officials, require that they be installed 12 inches (300 mm) higher than the highest outlet). Some municipalities do not allow the use of GFAVB’s. These units will NOT prevent backflow pressure and can only protect against back siphonage.

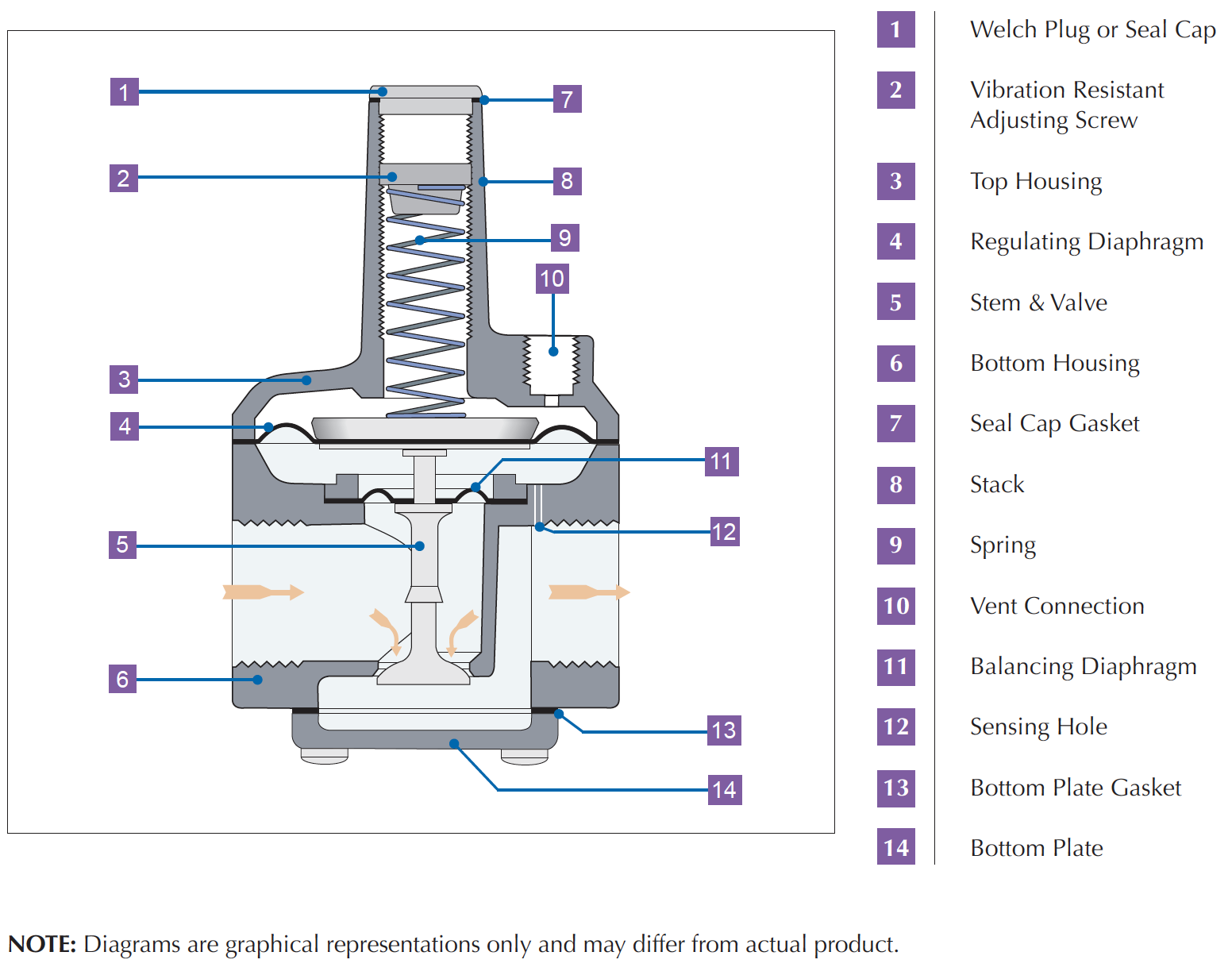

R Series regulators have a double diaphragm balanced valve design that makes is possible to maintain steady outlet pressure control with widely varying inlet pressures. R Series regulators are intended for use with both main burner and pilot load applications. Applications include infrared heaters and pilot lines on large industrial heaters and boilers. They may also be used in residential applications as appliance regulators.

8615510865705

8615510865705

8615510865705

8615510865705