Watts Regulator Co - Company Profile and News - regulator co.

Reduced Pressure backflow preventerinstallation

T-10 General Info Region Warsaw Pact Country USSR Ammo Available AP - APDS - HE - HEAT Elevation Arc 15° / -4° Previous Tank IS-7 Purchase Requirements Level Required (Gold) Cost (Gold) 170 Level Required (Silver) Cost (Silver) 1400 Base Stats Level 16 Health 310 Armor 105 Damage 103 Speed 24 kph Reloading 5.8 sec Turret Rot. 10 deg/sec Max Stats Level 24 Health 310 Armor 144 Damage 124 Speed 50 kph Reloading 4.8 sec Turret Rot. 18 deg/sec

PERFORMANCE RATING• Maximum Working Pressure of RP Backflow Preventer: 175 psi• Temperature Range: 33 ° F – 140 ° F• Hydrostatic Test Pressure: 350 psi

Reduced pressure backflow preventervs Double check valve

The biggest differences from its direct ancestor, the IS-3, were a longer hull, seven pairs of road wheels instead of six, a larger turret mounting a new gun with fume extractor, an improved diesel engine, and increased armour. The general performance was similar, although the T-10 could carry more ammunition. The T-10 (like the IS tanks they replaced) was deployed in independent tank regiments belonging to armies, and independent tank battalions belonging to divisions. These independent tank units could be attached to mechanized units, to support infantry operations and perform breakthroughs.

REDUCED PRESSURE BACKFLOW PREVENTER FEATURES• Domestic Stainless Steel Body: 2-1/2” – 8”• FDA Epoxy Coated Ductile Iron Body: 10” & 12”• Easy Maintenance – No Special Tools Required• Snap-In Check Retainers: 2-1/2” – 6”• Bolted-In Checks: 8” – 12”• Low Pressure loss as Documented by an Independent Laboratory• Center-Stem Guided TriForce™ Check Valves• Approved for Horizontal Flow• US Patents: 6,443,184; 7,025,085; 7,533,699; 8,240,333• Made in the USA – ARRA Compliant

Reduced Pressure Backflow preventerTest Procedure

The T-10 (also known as Object 730, IS-8, IS-9, and IS-10) was a Soviet heavy tank of the Cold War, and was the final development of the KV and IS tank series. During development, it was called IS-8 and IS-9. It was accepted into production in 1952 as the IS-10 (Losif Stalin, Russian form of Joseph Stalin), but due to the political climate in the wake of Stalin's death in 1953, it was renamed T-10.

Reduced pressure backflow preventerleaking

After grinding past the IS-7 the T-10 is a way more useful tank on the battlefield, the T-10 has ammunition compatibility with all types of ammo rounds except for ATMs (and rockets, obviously). It is an excellent all-round tank, and is arguably more of a "super medium" tank rather than a heavy tank as it was originally designed to be. For its level, the T-10 has more health and armor than almost all tanks that are around its person level range. Since the gun can deal some great damage, it only takes a couple or so shots to take out almost any other tank, except for other heavy tanks that also have thick armor and a big health pool. The excellent angle of the upper frontal armor will repel some shots, but mostly just from HEAT shells (as they are ineffective against angled armor) and enemies that don't have enough penetration to go through this glacis. The speed is medium, as it is a heavy tank, but actually pretty good for a heavy tank. The T-10 is excellent for going in the hull-down position, since its frontal turret armor is excellently sloped. When going on the offensive, it is best to get up close to the enemy so they have nothing to shoot at but the front of the turret.

APPROVALS• Sizes 2-1/2” – 8”: AWWA C511• Sizes 2-1/2” – 12”: ASSE 1013-2011, CSA B64.4, FM, IAPMO, UL*, cUL*• *UL and cUL installations Must Include Indicating-Type Shut-Off Valves• NSF/ANSI 61 Water Quality (2-1/2” - 12”)• NSF/ANSI 372 Lead Free (2-1/2” – 12”)• Approved by the Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California (2-1/2” - 8”)

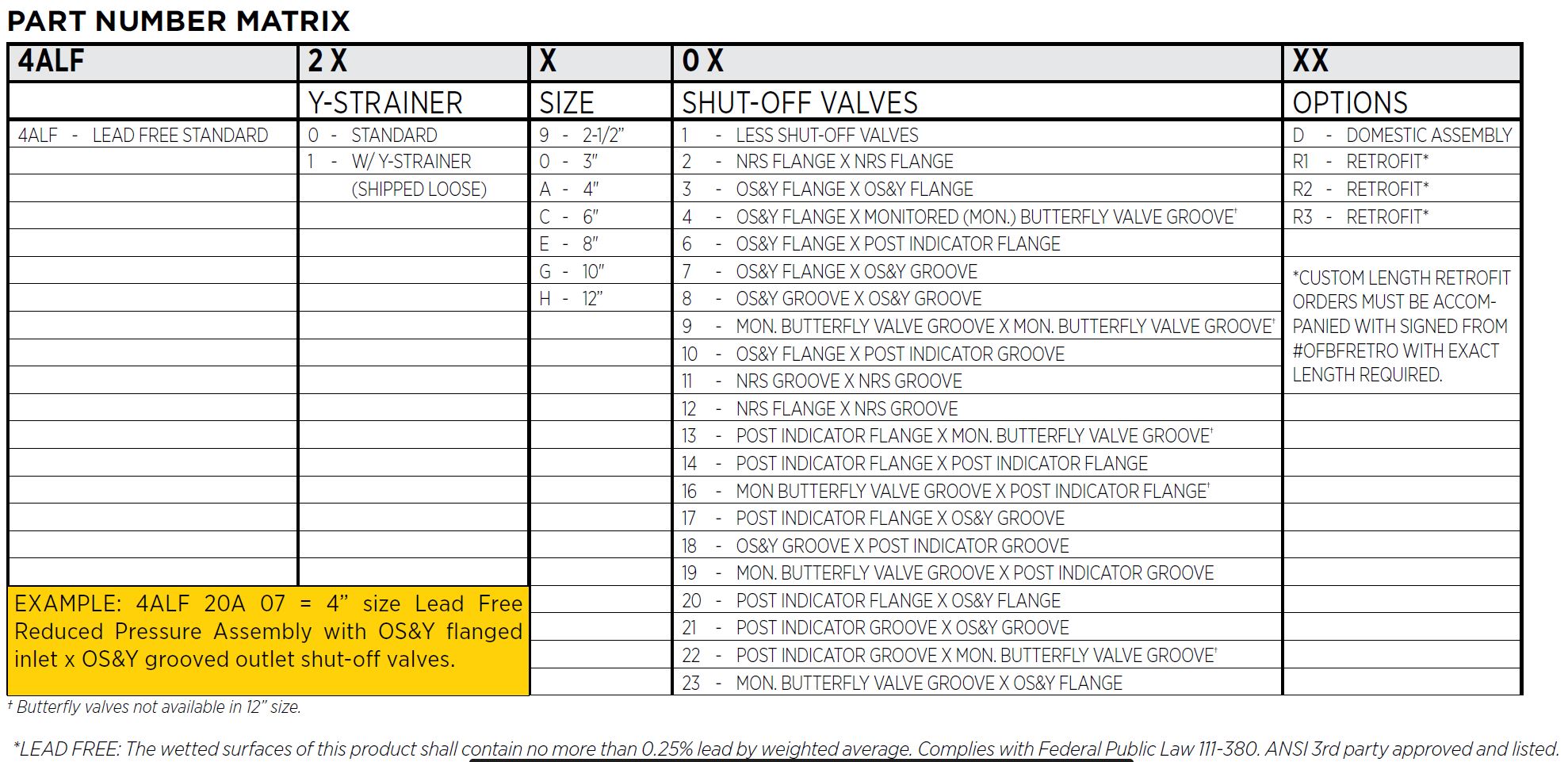

DESCRIPTIONThe Apollo® Model RPLF 4A Reduced Pressure Principle Backflow Preventers consist of two independently acting, TriForce™ center stem guided check valves with a differential pressure relief valve located between the check valves. This reduced pressure backflow assembly is designed to give maximum protection against backflow of health or non-health hazard fluids by either back-pressure or back-siphonage. The durable domestic stainless steel units (2-1/2”-8”) and the FDA epoxy coated ductile iron units (10” and 12”) are easily maintained in the line without any special tools. The TriForce™ check valves operate with a spring assist in the flowing condition to provide excellent flow rates which are documented by an independent laboratory.

8615510865705

8615510865705

8615510865705

8615510865705