Watts Regulator Co. 0112082 3 757DCDA-BFGxPIV-CFM - 757dcda

Pressure reducing valveworking principle pdf

Some common problems with pressure reducing valves include leaks, clogs, and incorrect pressure settings. Leaks can occur due to worn out seals or damaged components, while clogs can be caused by debris in the fluid. Incorrect pressure settings can lead to inadequate pressure regulation or excessive pressure drops. Regular maintenance and proper installation can help prevent these issues.

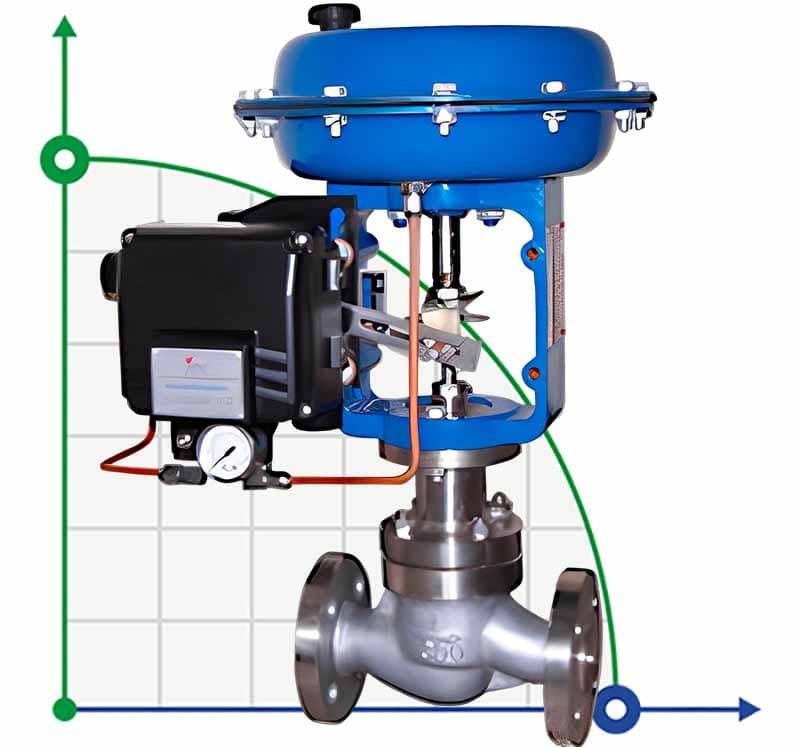

Download instructions, catalog for DN50 Slurry valve for boiler purge 10T11Y-16, WCB+304+STL trim, positioner YT-1000 10P1, input 4-20mA

Whatis the use ofa pressure reducing valvehydraulic

The purpose of a pressure reducing valve is to maintain a consistent and safe pressure level in a piping system. This is important for preventing damage to equipment and ensuring proper functioning of the system.

The performance of a pressure reducing valve is determined by several factors, including the type and quality of the valve, the fluid properties, and the flow rate. It is important to select the right valve for the specific application to ensure proper performance.

Pressure reducing valveworking principle

The pressure on a pressure reducing valve can be adjusted by turning the adjusting screw or knob on the valve. This changes the tension on the spring, which in turn affects the pressure of the outgoing fluid. It is important to follow the manufacturer's instructions when adjusting the pressure to avoid damaging the valve.

A pressure reducing valve works by using a spring-loaded diaphragm to regulate the flow of fluid in a piping system. The valve is designed to reduce the high pressure of the incoming fluid to a lower, more manageable pressure as it exits the valve.

8615510865705

8615510865705

8615510865705

8615510865705