Watts® Retrofit Repair Kit, Converts 800M4QT to 800M4FR ... - 800m4 repair kit

Series: Design Tools Title: HVAC Expansion Tank Design Calculator for Chilled Water Systems Author: Justin Kauwale, P.E. Units: English (SI Coming Soon) Language: English Format: Excel Publisher: Engineering Pro Guides Last Updated April 11, 2018

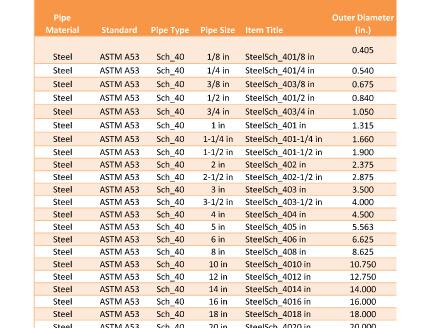

This figure shows the available pipe types within each pipe material. This is just a snippet of the calculator, there are many more pipe types and materials.

This figure shows the available pipe sizes within each pipe material & type combination. This is just a snippet of the calculator, there are many more pipe types and materials.

This calculator covers the design and selection of a chilled water expansion tank. The expansion tank is a part of an overall hot water system that often includes a hot water generator (fuel fired boiler), piping, valves/fittings, water treatment, hot water coils (air handling units and fan coil units) and hot water pump(s). A hydronic system is a water system that is used to transport heat from one location to another. Typical hydronic systems include chilled water and hot water systems. This guide is on hot water systems, these systems have additional sub-systems based on the temperature of the system. Low temperature systems are defined as hot water systems less than 240 °F. Medium/High temperature systems are defined as hot water systems above 240 °F.

The calculator comes with all the standard pipe types used in chilled water systems, like steel (schedule 40 and 80), copper (type K, L, M), polypropylene, PVC, etc. The calculator automatically determines the inner diameter and inner area of your selected pipe.

Justin Kauwale PE, LEED AP is a professional engineer that is registered in both Mechanical and Fire Protection Engineering. He has over 11 years of experience in practicing and teaching engineering to practicing engineers. He is the owner of this website and the creator of this content. If you have any questions, please contact him at contact@engproguides.com or see the about page for more.

Features · Bolted Bonnet · 1/4" NPT Test Plug Upstream and Downstream · Flange: ASME B16.1 · Pressure Rating: Class 125.

Adjustable steam air vent. Nonvacuum float type steam air vents are designed to vent air on nonvacuum steam heating systems. Use on radiators,...

2024923 — Trappex 1/2" Water Shock Arrestor - Mechanical. Maintenance free device to prevent water hammer in plumbing systems. No need to re-pressurize ...

Take a look at our repair kits for pressure reducing valves, which includes factory approved components to help you fix your broken items.

Website: www.engproguides.com Email: contact@engproguides.com Contact Page: Contact Us Company: Engineering Pro Guides

Engineering Pro Guides provides mechanical and electrical PE and FE exam technical study guides, practice exams and much more. Contact Justin for more information. Email: contact@engproguides.com

A backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow. In this situation, dirty water from ...

This product is yours to use risk-free to you. If you are not completely satisfied with your improved efficiency after two weeks of use, then simply email me a note about experience within two months of the original purchase date for a complete refund of your purchase price , no questions asked.

If the valve's seal or internal components are damaged, it might not close properly after releasing pressure, resulting in a persistent run of water. Relief ...

FEBCO SPECIFICATION SHEET NO. 825Y (¾¼ — 2″). Model 825Y (3/4" through 2"). Reduced Pressure Backflow. Preventer For High Hazard Service. Characteristics and ...

The outputs of the calculator is a summary of the various piping volumes, the specific volume at the high and low temperatures and ultimately the expansion tank size. From design to construction, there will be variations to the system and you can account for those variations with a safety factor, which is also shown in this figure.

The HVAC Expansion Tank Calculator for Chilled Water Systems is designed to be comprehensive to apply to nearly all condenser water designs, but also simple and easy to use. The interface is in excel format which makes it easy for anyone to quickly learn. You are able to add in extra rows to your volume calculation similar to how you would with excel. Inputting data is simple and intuitive, just follow the examples within the calculator. Change pipe material, pipe sizes, temperatures, pressures, etc. and have the calculator automatically determine the total volume in the system. The references that create the basis of this calculator are also editable such that you can customize fluid values or add-in pipe sizes. However, if you do not feel comfortable making changes, then simply email me and I will customize the spreadsheet to suit your needs. The calculator also beautifully prints to a standard 8.5 x 11 format for your basis of design or other design report appendix. The calculator will determine the total volume of the expansion tank and will also give you a schedule template to be used on your drawings. Hawaii general excise tax is not included in the cost below and will be added to the final cost.

This figure shows hot the pipe type and pipe size within the type will determine the diameter, which will determine the inner area. The inner area then determines the volume of chilled water within the system at the low temperature.

The first distinguishing factor of Engineering Pro Guides is our design guidance that comes along with each calculator. This calculator comes with a detailed and easy to understand guide on how to the calculator. It also explains the background of the creation of the calculator. Since, we are also engineers who use these calculators regularly, we also are able to explain the engineering design behind expansion tanks, which makes it easier to understand the calculator and use the calculator.

As an experienced engineer you should be able to quickly and accurately size and select your expansion tank. Each hydornic hot water system is different, but this calculator takes the most common piping and fluid properties to make the most comprehensive expansion tank calculator on the market. This calculator also comes with a detailed instruction manual that does not only explain how to use the calculator but also explains how to design an expansion tank with easy to use verbiage and figures. For example, the guide walks you through, how to locate the expansion tank within the system.

Download the instruction manual and whitepaper Expansion Tank Calculator for Chilled Water Systems - Whitepaper. Learn about the design experience and equations behind the calculator. The calculator has an instruction manual specifically on the calculator and how to use the calculator, but this PDF also includes design instructions.

2024617 — Are you looking for backflow valves? Find everything you need to install or repair your system with complete backflow valve kits to spare parts ...

A Double Check Detector Valve Assembly (DCDA) is a device that is used to prevent backflow in a fire water distribution system.

Why You Need an Expansion Tank with a Closed-Loop System. The brief answer? An expansion tank will prevent damage to your water heater and plumbing system.

It takes a team effort to provide effective, compassionate care to those who need it, and our team is dedicated to serving those needs. From the personal attention you deserve to delivering the service and products that fit your lifestyle, we strive to ensure that your daily life is made easier. Remember, you can choose your medical equipment provider - exercise that right and choose the company that sets the standard.

Another distinguishing factor of Engineering Pro Guides products is that EPG answers questions promptly and also shares the questions and answers with all customers and potential customers. This open communication makes it very easy to overcome any problems you may have in using the calculator.

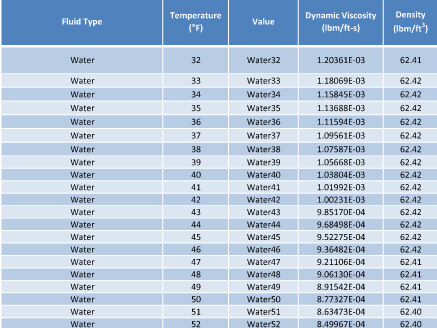

The calculator also includes the fluid properties of water and gylcol-water mixtures at all temperatures within the chilled water typical range. This figure shows how the density (specific volume) is automatically found, when you input the fluid type and fluid temperature. The specific volume and temperature is very important, because it determines how much the fluid will expand from its lowest temperature to its highest temperature.

8615510865705

8615510865705

8615510865705

8615510865705