Backflow Repair Parts Febco 3/4" 765 - febco 765 pvb

Go ahead and water test; there is a good chance that if and when you find leaks in the connections, use both hands and shift the piping slightly till the leaks stop, sometimes water works in mysterious ways and will actually "seat" the connections and will be leak proof. Has to do with the expansion of the connections.

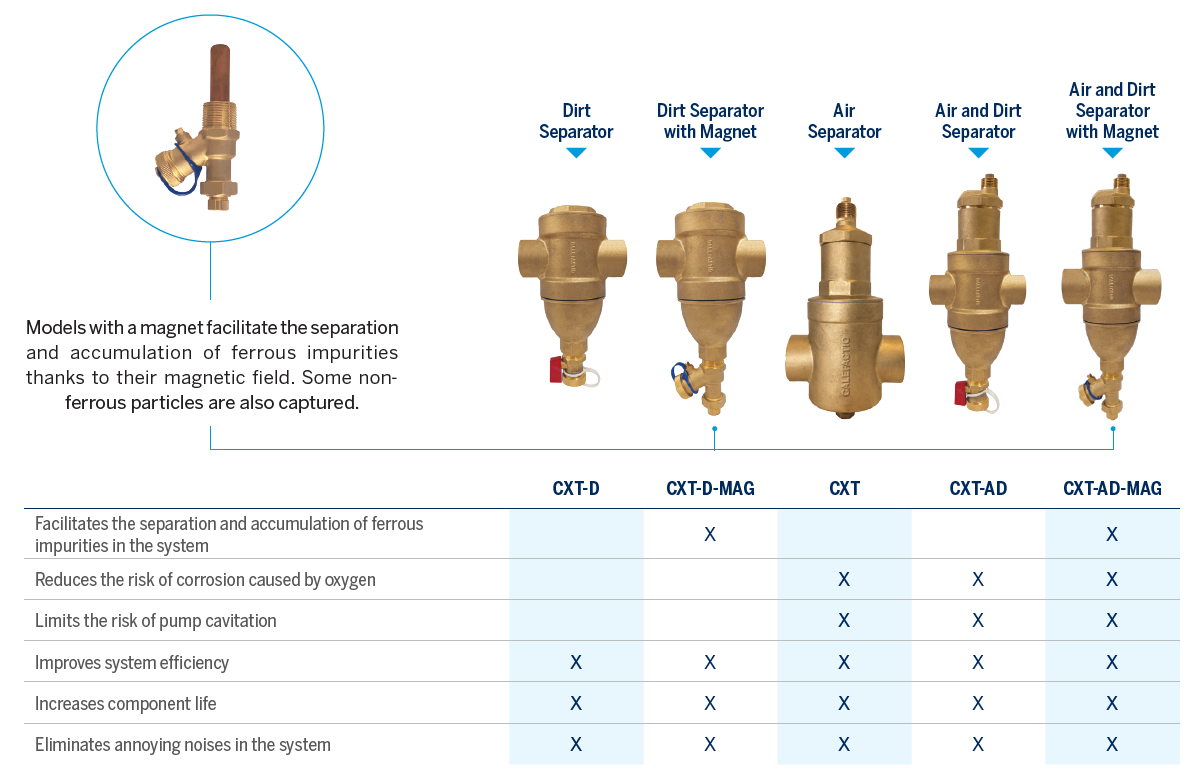

They are equipped with a stainless steel bristles coalescing media to catch the finest micro-bubbles and air without affecting the flow. The coalescence process produced by the media allows air and micro-bubbles to fusion and then be evacuated through the Calvent automatic vent.

Their function allowing a better energetic performance while reducing the costly maintenance frequency. Their sturdy design allows to maintain their efficiency for whole duration of the system’s lifetime.

Questions? Orders? Need information? Leave us your contact information and details on your request and we will contact you within one business day.

Welcome to Plbg.com (also known as PlumbingForum.com) where plumbing advice, education, information, help and suggestions are provided by some of the most experienced plumbers and plumbing contractors anywhere who all wish to "give back" to society. Since 1996 we have been free without popup or other invasive ads and known to be the best online STRICTLY PLUMBING advice site. If you have questions about plumbing, toilets, sinks, faucets, drains, sewers, water filters, venting, water heating, showers, pumps, and other strictly PLUMBING related issues then you've come to the right place. Please refrain from asking or discussing legal questions, or pricing, or where to find and/or purchase products, or any business issues, or for contractor referrals, or any other questions or issues not specifically related to plumbing. Keep all posts positive and absolutely no advertising. Our site is completely free, without ads or pop-ups and we don't track you. We absolutely do not sell your personal information. We are made possible by:

The Cal-X-Tract air product line from Calefactio reduce the risk of corrosion and damage that could be caused by the oxygen and micro-bubbles in the systems of heating.

The "Orion" acid waste is very easy to install. Care must be taken to have straight cuts and the edge of pipe should be reemed/deburred. It is important to tighten each bolt evenly. Most that I have installed can be tightened all the way or close to all the way. Orion specificly states not to air test so maybe they know something we don't. I would try a water test slowly and see how it holds. I believe the groove is so the pipe does not slip from the clamp. Any small leaks should be able to be caught with a bucket or wiped with rags. The groove tool is easy to use, but care must be taken to not let the groove run. The blue piping is fire rated and the brown piping is not. You can go to the "Orion" websit for more info. GOOD LUCK

Hi, We're using "Orion" brand for this acid waste job i'm on right now. I've used enfield and fuseal in the past with success, but this product for whatever reason is turning out to be a nightmare. The manufacturer recommends a water test over air but i put on an air test first just to see what would happen. Couldnt' get it over 3/4 lb psi and just about every single joint is leaking. This is a mechanical style joint coupling with a grove on the pipe. I read the installation instructions and thought i was putting it together the proper way, but something obiously isin't right. Anyone have experience with this product or any advice? Thankyou very much.

Calefactio automatic air vents remove trapped air to restore maximum pressure in a system. Made of brass, they can withstand temperatures as high as 120° C / 248° F (for solar air vents: 230° C / 446° F). These...

We had a problem holding an air test a few years ago on an acid waste for a school also. They solved it by using a lubricant such as you would use on Ty-seals and cast iron pipe and on another small job they used pvc glue and then cranked the fitting tight. I belive that is why Orion says to water test because; it acts as luricant and sealer and as everone should know air will pass through very minute spaces where water won't. You will get it to work sooner or latter just let us know how you did it. Post Edited

If you can not get more then 3/4# PSI on an AIR TEST, THEN YOU HAVE LEAKS, However you already know that, you are using mechanical joints, which means the you need to EAT YOUR WHEATIES, ONE of the SECRETS for mechanical joints especially when dealing with caustic products, (ie:Unions) Is to double wrench them and then Strongly TAP then fitting with a hammer while you are applying tightening pressure to the joint, If this does not solve the problem then you need to replace the mechanical joint, It most likely has a flaw or is MIS-MATCHED, Unions are ground as a matched set IF you mis-match a union then it WILL LEAK. Are you dealing with Large pipe 2" or more? What Specifically are you dealing with? (Commercial, industrial, residential). Plumbermandan

I have not used Orion, but it could be like water main gaskets. It requires the water under pressure to enter the Wedgelok gasket and expand it against the pipe walls. Air doesn't do it because it can leak out rather than expand the gasket.

This is a science lab for a school. 1 1/2" to 4". No unions here, this is plastic pipe with couplings similar to no-hub bands but of a tougher and less flexible material. The pipe has to be grooved and there is a ridge on the inside of the coupling that fits with the groove to create the seal. 1/2" ratchet is used to tighten the clamps around the coupling. Thanks again for your help.

8615510865705

8615510865705

8615510865705

8615510865705