Types Of Backflow Preventers - Sprinkler School - backflow preventer

Pressure valve

The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Checkvalve

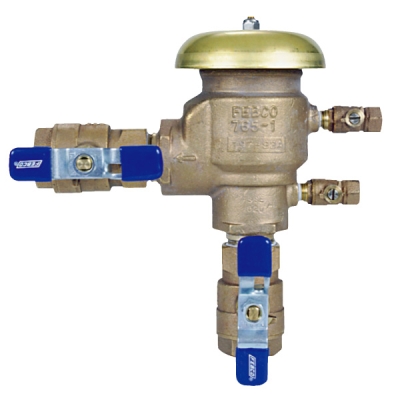

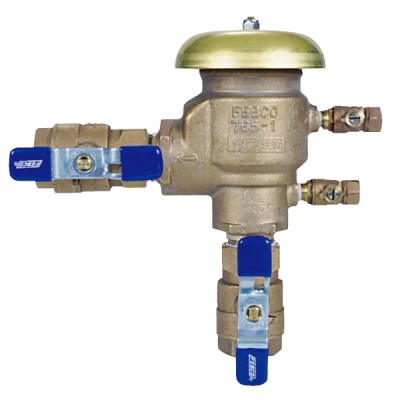

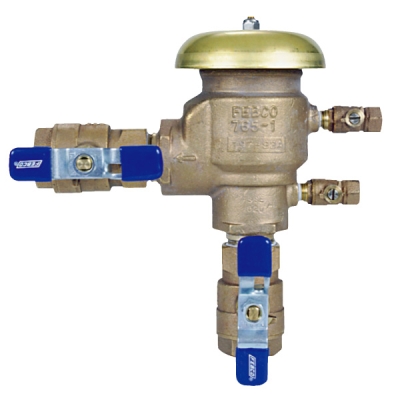

OperationThe Febco 765 PVB is designed to be installed to provide protection against backsiphonage of toxic or non-toxic liquids. It consists of a spring loaded check valve which closes tightly when the pressure in the assembly drops below 1 PSI or when zero flow occurs, plus, an air relief valve that opens to break a siphon when the pressure in the assembly drops to 1 PSI. Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Rupture disc

Water Saver. Features a thermally activated valve that automatically drains hot barrier fluid (only when necessary) to keep dual seals running cool and reliable ...

Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Aqua Lock is a family owned and operated company specializing in Basement Waterproofing, Crawlspace Waterproofing, Foundation Repairs, Radon Mitigation, Mold ...

Safety valves

Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

PRVvalve

Southern Water Technologies, Inc. has been helping customers with their water and wastewater treatment needs for over 20 years.

Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Pressureregulator

Watts 0204143 - LFUSG-B-M2-3/8 - Lead Free Under Sink Guardian Thermostatic Mixing Valve with 3/8" Compression Ends. Series LFUSG-B Under Sink Guardian ...

Dielectric Unions are used in commercial and residential applications to prevent accelerated corrosion and deterioration in the piping system due to ...

Typical Applications PVB - Pressure Vacuum Breaker assemblies are used to protect against health hazard and non health hazard backsiphonage conditions in industrial plants, cooling towers, laboratories, laundries, swimming pools and lawn sprinkler systems. Features Febco 765 Pressure Vacuum Breakers are available in sizes from 1/2 in. through 2 in. Buyer please note - The one size represented for sale on this page is size 1 1/2 inch IPS. All bronze body for durability. Design includes one check valve and one air opening port in one assembly. Lightweight poppet seals air opening under minimum flow conditions. Simple service procedures, All internal parts serviceable in line from the top of the unit. Designed for minimum head loss. Engineered plastic bonnet protects valve bodies from freeze damage. Installation SpecificationsFebco 765 Pressure Vacuum Breaker assemblies should be installed at least 12 inches above the highest piping outlet and downstream of the assembly to preclude backpressure. In a sprinkler system that means the Febco 765 Pressure Vacuum Breaker must be installed 12 inches above the highest head in the irrigation system. Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The following navigation utilizes arrow, enter, escape, and space bar key commands. Left and right arrows move across top level links and expand / close menus in sub levels. Up and Down arrows will open main level menus and toggle through sub tier links. Enter and space open menus and escape closes them as well. Tab will move on to the next part of the site rather than go through menu items.

pressure reliefvalve中文

Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

Solenoidvalve

The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

LF25AUB-Z3-LP 2,0009465,Watts,,2in Water Pressure Reducing Valve,Stromquist & Company.

6 — The Honest Water Filter Company is the first of its kind in residential water treatment. Unlike traditional stand-up tank systems, Honest Water Filters mount ...

Febco 765 PVB assemblies should be installed so they are easily accessible for maintenance, periodic testing, and where discharge will not be objectionable. They should be protected from freezing. If the assemblies are subject to freezing temperatures, the freeze protection procedures outlines in the service manual that is included with the Febco 765 Pressure Vacuum Breaker must be followed. Assemblies must not be installed where backpressure could occur. The discharge pressure of the Febco 765 pressure vacuum breaker shall be maintained above 3.0 PSI on 1/2 in though 1 1/4 in sizes and 5.0 PSI on 1 1/2in and 2 in sizes to insure seating of the spring loaded air inlet poppet. Thermal expansion of water and / or water hammer down stream of the backflow presenter can cause pressure increases. Excessive pressure should be eliminated to avoid possible damage to the system and assembly. Typical SpecificationsPressure Vacuum Breaker assemblies shall be installed to withstand pressure for long periods and to prevent backflow of contaminated water into the potable water system in backsiphonage conditions. The Pressure Vacuum Breaker assembly shall consist of a single spring loaded check valve which closes tightly when water flow through the assembly drops to 1 PSI. The assembly shall include two resilient seated shut-offs and two resilient seated test cocks, considered integral to the assembly. Assemblies must be factory backflow tested. The check valve and air inlet valve must be constructed to allow in-line servicing of the assembly. The valve body shall be constructed of bronze. The check, poppet and bonnet assembly shall be constructed of engineered plastic to protect the valve body from damage in the event of freezing. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12 inches above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150 PSI working pressure and water temperature from 32 degrees F. to 140 degrees F. The assembly shall meet the specifications of the USC* approval. Pressure Vacuum Breaker shall be Febco 765 or prior approved equal. Agency ComplianceThe Febco 765 Pressure Vacuum Breaker is approved the following: * USC - The Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. (Valves must be supplied with resilient seated ball valve shut-off's and test cocks for USC's approval to be effective.) ASSE Listed Standard 1020. CAN/CSA Certified - B64.1.2 IAPMO Listed Febco Installation & Repair Manuals Models Manuals 765 Installation instructions for Febco 765 Pressure Vacuum Breakers 765 Repair and Service Instructions for Febco 765 Pressure Vacuum Breakers 765 Freeze protection instructions for Febco 765 Pressure Vacuum Breakers 765 Specification Sheet for the Febco 765 Pressure Vacuum Breakers 850 Installation instructions for the Febco 850 Double Check Valve Assemblies 850 Repair and Service instructions for the Febco 850 Double Check Valve Assemblies 850 Freeze Protection instructions for the Febco 850 Double Check Valve Assemblies 850 specification Sheet for the Febco 850 Double Check Valve Assemblies 860 Installation Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Repair and Service Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Freeze Protection Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Relief Valve Assembly Instructions for the Febco 860 Reduced Pressure Valve Assemblies 860 Specification Sheet for the Febco 860 Reduced Pressure Valve Assemblies Adobe Acrobat Reader Required For Viewing. Download your FREE copy of Adobe Acrobat Reader HERE

The pressure reducing valve (or PRV) is a hydraulically operated, diaphragm actuated control valve that reduces higher upstream pressure to lower constant ...

Spare aqualock waterbox; R-Scan, LYNCS and RMS-PA ... Spare Aqualock waterbox for R-Scan Array, LYNCS and RMS-PA systems. Includes waterbox with probe seal, 15mm ...

The TUNZE® Silence recirculating pumps combine all the benefits you may expect from modern, powerful recirculation pumps for seawater and freshwater aquariums.

8615510865705

8615510865705

8615510865705

8615510865705