Air Gap Backflow Prevention - (619) 527-2525 - backflow preventer air gap

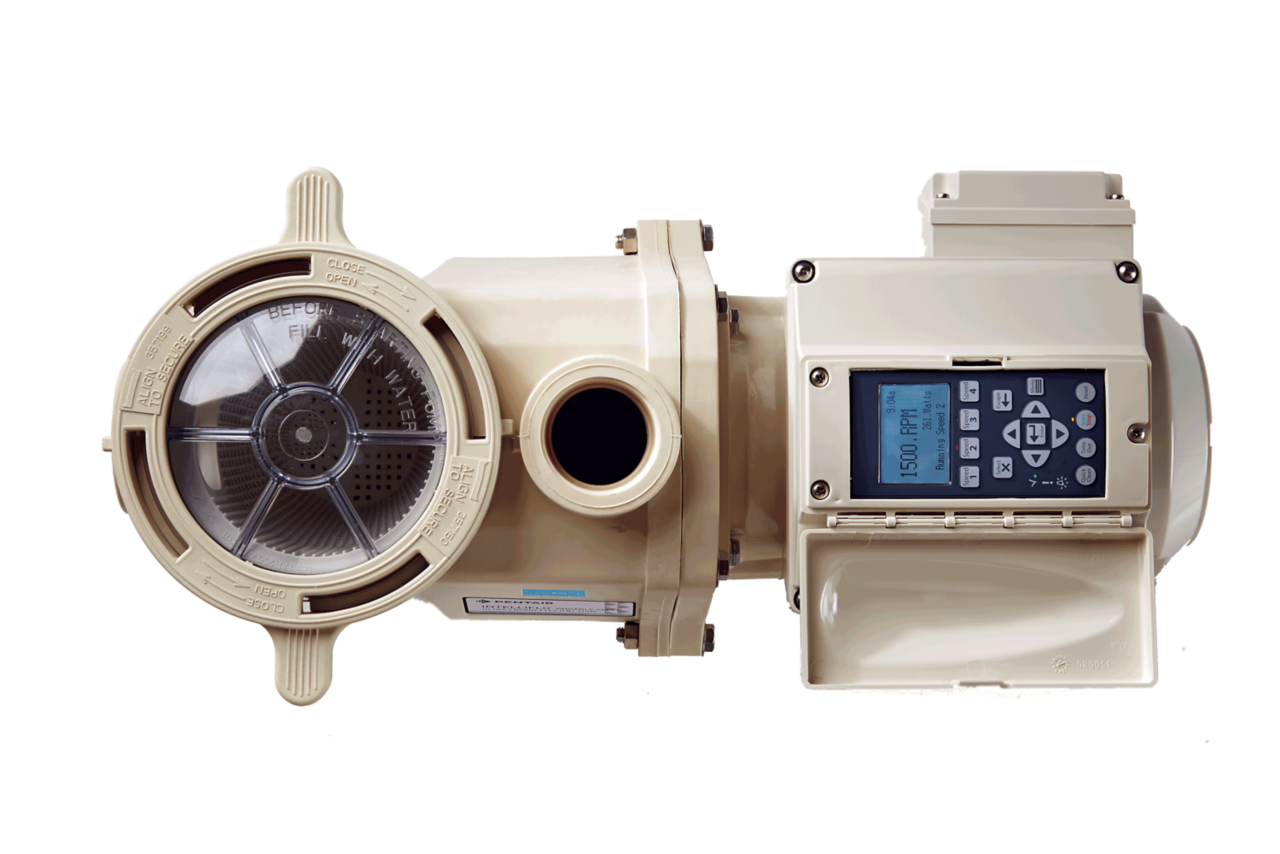

IntelliFlo VS Variable Speed pump is the next generation of Pentair's variable-speed pump technology. With energy savings up to 90%* versus conventional pumps, near-silent operation and advanced programming capabilities, this pump continues to deliver everything a pool owner wants and reliability no other competitor can match.

Products beginning with EC- are exclusive to e-commerce sales. For warranty information please visit www.pentair.com/warranty.

The IntelliFlo high-performance variable speed pool pump features the smartest pump technology available. This results in increased energy savings over conventional single- or two-speed pumps, up to 90%.*

Manufacturers will be able to provide you the relevant graph to determine how much water you can expect to discharge so that you can size the drain accordingly.

CASE STUDIES Greengate, UK "I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software. The ability to output the design straight into Revit assisted clash detection and coordination." Read the full case study

As an example, if you were connecting a potable water supply to the HVAC system, this would require backflow prevention because of the chemicals used in the HVAC system.

CASE STUDIES Salon Republic, USA "The quality of the designs saw significant improvement with the adoption of h2x." "The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop." Read the full case study

CASE STUDIES Award-Winning Heating Design "Using h2x was pivotal, allowing for precise heat loss calculations, pipe sizing and flow rates for each room. This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort. The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance." Read the full case study

An honest mistake that is commonly made is connecting fixtures that are used for personal hygiene downstream of the RPZ because it is in the same room. This results in a design that is not fit for purpose and it is also non-compliant.

Backflow is the reversal of the intended direction of water flow. This occurs when there is a significant drop in pressure in the upstream water supply which is commonly caused from water main failures.

From our residential and commercial water solutions, to industrial water management and everything in between, Pentair is focused on smart, sustainable water solutions that help our planet and people thrive.

The sink requires the RPZ to prevent the chemicals entering the potable water supply. However, if you connect the basin downstream of the RPZ too, the design will allow chemicals to come out of the basin where someone expects it to be potable and could therefore potentially consume.

As you can see in the example below, if you have a flow rate of 0.6 l/sec (25mm pipe at a 1.5 m/sec maximum velocity), you can use either a 20mm or 25mm RPZ valve and experience a similar amount of pressure loss.

As an example, if you were connecting a potable water supply to the HVAC system, this would require backflow prevention because of the chemicals used in the HVAC system. If the chemicals that are used in the HVAC system were able to enter the potable water supply, consumption of that water would pose a significant risk to public health.

They discharge more than you expect and you need to have a sufficient drain below the RPZ valve to cater for it. In the example below, a 20mm RPZ with an incoming pressure of 483 kPa will discharge 2.4 l/sec.

Are there any other important design items that you would like to see included in this article? Let us know in the comments.

The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance."

A medical centre in Midwest U.S. saw the deaths of two patients who had unfortunately consumed water that was supposed to be potable (safe to drink). As there was no RPZ on the potable water supply to the HVAC holding tank where chemicals were mixed, when backflow occurred in the system, the chemicals made their way to the outlets of the basins and sinks throughout the medical centre.

"I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software.

Regular maintenance is required for RPZ valves to ensure they operate correctly on an ongoing basis. With this in mind, it is important to design with the following considerations:

3 'APSP' Pump has been evaluated to ANSI/APSP/ICC-15 and California Title 20 and is certified to use on Residential Swimming Pool Filtration Systems.

The image below shows how backflow can occur as a water main fails and also highlights the consequences when backflow prevention is not installed correctly. As shown, the water main fails and there is no backflow prevention installed to stop the toxic chemicals entering the ‘potable’ water supply to other buildings.

2 ‘NSF’ indicates that pump bears a mark signifying evaluation to NSF Standard 50 For Self-Priming Centrifugal Pumps For Swimming Pools Only.

This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort.

In the example below, there is a cleaners room that has a sink (used for mixing chemicals) and a basin (used for personal hygiene).

4 Product may have been evaluated to other state and local regulatory standards. Listing status may change. Always confirm status with appropriate agency if in doubt.

"The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop."

1 ‘UL’ indicates that pump bears a UL mark signifying evaluation to U.S. Standards UL1081 for Permanently Connected Swimming Pool and Spa Pumps and to Canadian Standards CAN/CSA C22.2 No. 108-01 Liquid Pumps For Swimming Pools Only (Enclosure 3).

Manufacturer’s usually have an easy to read graph that will enable you to quickly determine the correct RPZ valve size and the corresponding pressure loss. Note the RPZ does not always need to match the pipe size on the inlet to the RPZ.

*Savings based on variable speed pump compared to a single-speed pump running 12 hours per day at an average of $0.16 per kWh in a 20,000 gallon pool. Actual savings may vary based on local utility rates, pool size, pump run time, pump horsepower, pump rpm, plumbing size and length, pump model, service factor and other hydraulic factors.

8615510865705

8615510865705

8615510865705

8615510865705