Appliance Parts, Accessories & Water Filters - water filter replacement parts

MuellerSteamspecialtycheck valve

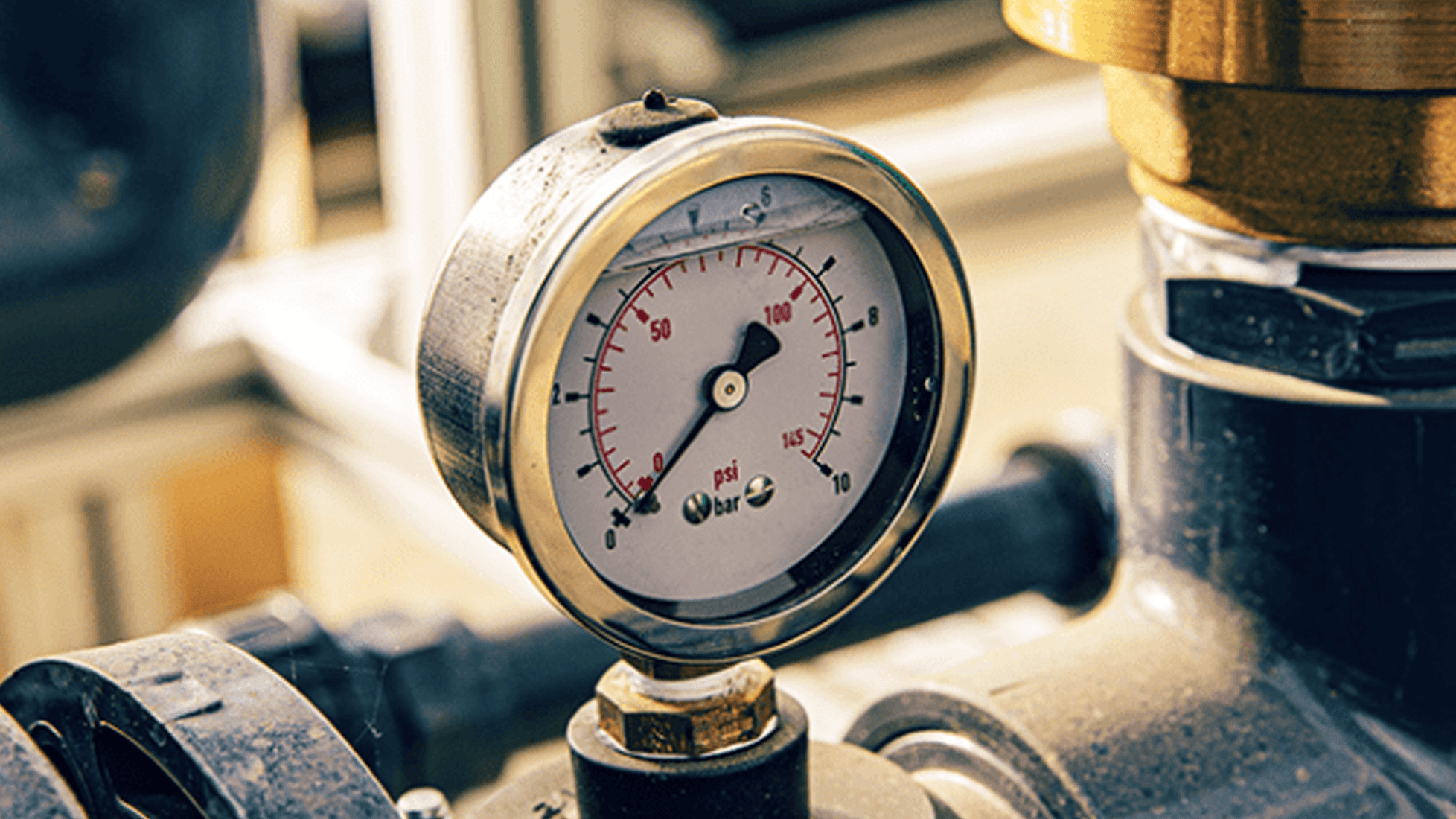

In general, the pressure drop is determined by multiplying the fluid velocity, the fluid density, and the head loss, which is the equivalent of the pressure drop in terms of the height of the fluid.

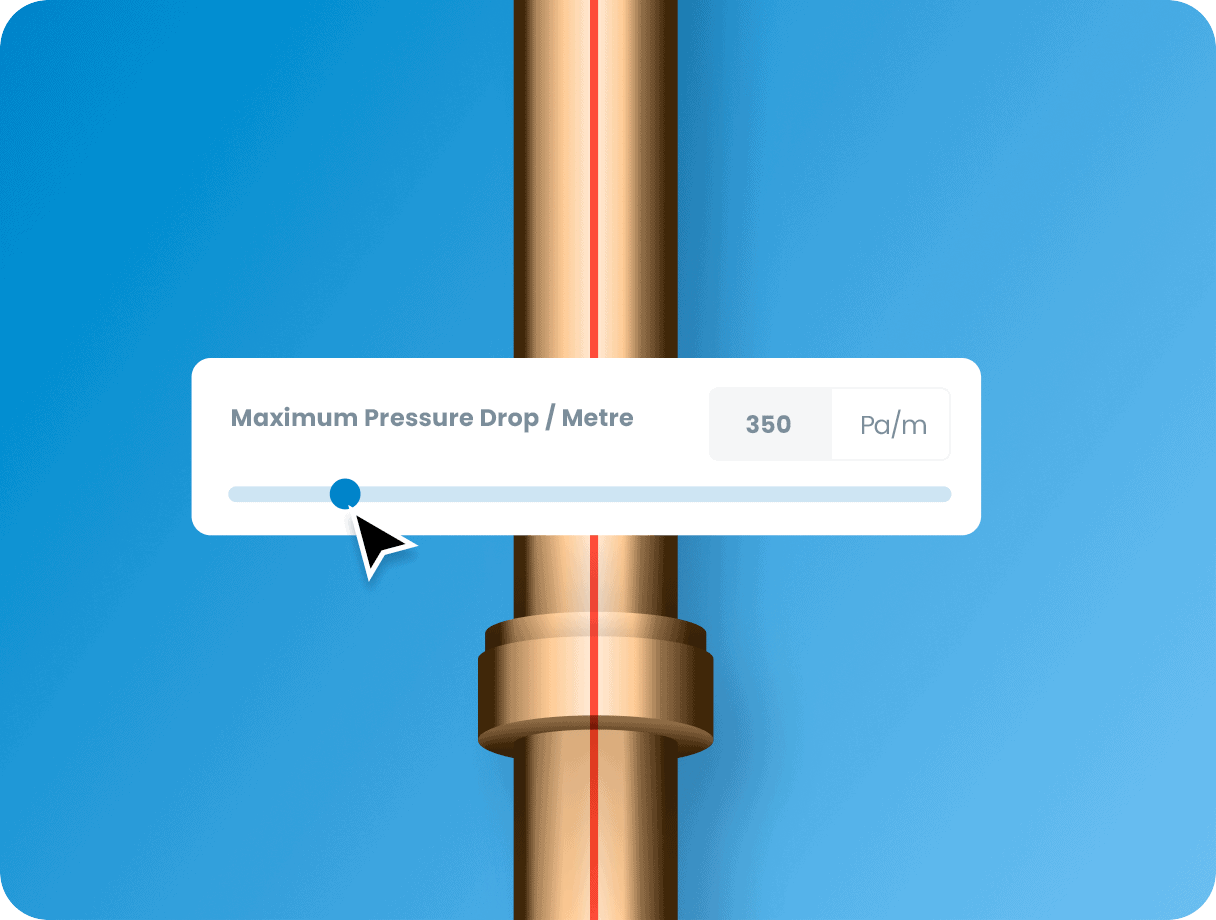

With advancements in technology, pressure drop calculations have become much easier with a pressure drop online calculator.

MuellerCo

As the Reynolds number (Re) exceeds 2000, the transition from laminar to turbulent flow occurs, marking a point where pressure drop calculations become more complex.

The amount of pressure (in psi) lost per foot of pipe depends on several factors, including the pipe diameter (pipe d), the pipe roughness interior surface, the velocity of the fluid flowing through the pipe, the flow rate, and the density of the fluid.

The friction factor (f) can be determined using several methods, such as the Moody diagram or the Colebrook equation, depending on the pipe roughness interior surface and the Reynolds number of the fluid flowing through the pipe.

Whether you're a seasoned professional or just starting, this guide will give you a comprehensive understanding of pressure drop, its calculations, and how our online calculator can help.

MuellerIndustries

It can be calculated using fluid dynamics principles, and the specific equation used will depend on the conditions of the piping system.

MuellerY strainer catalog pdf

There's a reason we are rated 4.9/5 for customer support on Capterra. Our integrated help button means that a real engineer will assist with any design query, no matter how big or small.

Several factors, including friction between the fluid and the interior surface of the pipe, the presence of fittings and valves, and other losses, cause this decrease in pressure.

JavaScript seems to be disabled in your browser. You must have JavaScript enabled in your browser to utilize the functionality of this website.

The pipe roughness and pipe length (pipe l) will result in a higher pressure drop, while the opposite will result in a lower pressure drop.

In contrast to laminar flow, where fluid particles move in parallel layers, turbulent flow rate involves eddies, vortices, and mixing of fluid particles.

MuellerStrainer 758

These parameters are used in calculating pressure drop, and the specific values will depend on the specific conditions of each piping system.

Saves time by providing quick and easy calculations, eliminating the need to perform complex mathematical calculations manually.

To accurately determine the pressure loss in a specific piping system, a calculation using fluid dynamics principles is required.

Calculate velocity through a pipe quickly and easily, eliminating the need to perform complex mathematical calculations manually.

Pressure drop calculations are crucial for ensuring efficient operation and preventing damage to equipment. Whether you're dealing with laminar or turbulent flow, our online calculator provides accurate results.

MuellerStrainer

Find out how much water volume is in your pipe by simply inputting the pipe diameter (pipe d) and the pipe length (pipe l).

The head loss is calculated using the friction factor, which accounts for the resistance to flow caused by the pipe roughness of the interior surface.

Commercial Industrial Supply offers Mueller Steam Specialty products and can get you the best deals on strainers and specialty products. Our staff is knowledgeable and can help you find the perfect filtration solution! For more information on products and pricing, submit our online quote request form or give us a call at 866-777-8001.

MuellerStreamline

The irregular motion and increased mixing of fluid particles in turbulent flow lead to higher energy dissipation and pressure losses.

There is no set value for pressure loss per foot of pipe, as it varies based on the specific conditions of each piping system.

Commercial Industrial Supply is an Official Authorized Distributor for Mueller Steam Specialty, the world’s largest supplier of strainers and the number one provider of specialty products serving the valve industry.

The pressure drop in a pipe depends on several variables, including fluid density, fluid velocity, flow rate, pipe diameter (pipe d), pipe length (pipe l), pipe roughness, fluid viscosity, and acceleration due to gravity.

MuellerSteamSpecialty

As the calculation can be measured in terms of ft/second and m/second, there are two different calculation methods to establish pressure drop:

User-friendly and requires no special training or technical knowledge. Just provide the input and receive detailed results.

Mueller Steam Specialty is a brand of Watts that was founded by Joseph Watts in 1874 on the belief that water boilers in textile mills shouldn’t explode. What started with a pressure relief valve in a tiny New England machine shop, has paved the way for today’s high-quality, worldwide water solution technologies. From melting ice on entire city blocks from the ground up, to filtering safe drinking water in isolated, weather disaster zones, you need water and water needs Watts.

It's important to note that the above formula is a simplified version of the pressure drop equation, and there may be other losses (such as fittings, valves, etc.) that need to be considered when calculating the total in a piping system.

A more viscous and higher-velocity (flow rate) fluid will result in a higher pressure drop, while the opposite will result in a lower pressure drop.

8615510865705

8615510865705

8615510865705

8615510865705