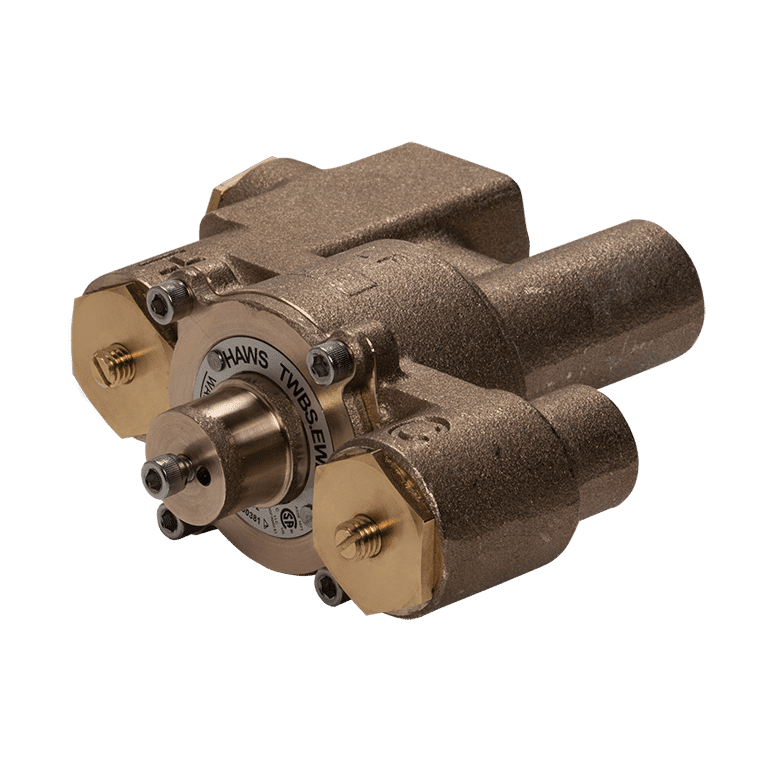

Backflow Preventer Valve, 3/4" FPT, With Strainer - 3 4 backflow preventer

We offer traditional phys chem systems such as clarifiers, dissolved air flotation, coagulation and separation to provide a complete solution.

Envirogen Technologies is part of the Envirogen Group, based in the United Kingdom. For more information on Envirogen Group, visit http://envirogengroup.com.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Full time or part time operations and maintenance of water treatment systems, both Envirogen installed or installed by others.

Model 9201EFE Emergency Thermostatic Mixing Valve (patent pending) thermostatically mixes hot and cold water to provide a safe fluid supply for emergency eyewash equipment. Additionally, to ensure a fail-safe water supply for emergency eyewash stations, a series of cold water by-pass valves open in the event of hot water pressure loss. (No gauges supplied - ASSE 1071 standard recommends gauges be placed 5 to 8 feet (1.52 to 2.44 m) downstream for the most accurate temperature measurement.) A flow rate of 1 to 12 gpm (3.8 to 45.4 L) for better temperature control across the operating range AXION's superior design and technology provide a complete safety solution for increased victim comfort. Lowest internal pressure drop for this class of valve (advantage where supply pressure is low) Wax based thermostat technology for fast response time with proven highly reliable temperature control Highest Cold Water Bypass flow rate in the industry (83% of rated tepid flow rate) Brass valve design with internal check stops Over-sized valve seats resist failures caused by foreign matter A new and efficient shuttle design eliminates Thermostatic Mixing Valve sticking A custom funnel design improves temperature control at low flow rates Outlet temperature is factory set to 85° F (29° C). Tempered water: High temperature limit is factory set to 90° F (32° C). Cold water by-pass valves are closed during normal operation, regardless of flow rate. For important installation information, please read Scald Warning. CSA Listings: CSA certified per ASSE 1071, ANSI/ISEA Z358.1 and applicable sections of CSA B125.3.

VeoliaWater Technologies& solutions

Prop 65 Warning. For California Residents Warning: This product contains a chemical known to the State of California to cause cancer and/or birth defects or other reproductive harm. Please click here for more information.

More than just hydration, RIVIVE is a statement of intentional engineering design for the convenience of end-users, facility managers, specifiers, and installers.

Remove even the toughest dissolved chemical such as metals and organics with an array of adsorptive technologies including activated carbon, ZVI, and greensand.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Using natural bacteria to break down the most difficult contaminants, our FBR's have effectively solved problems for mines, superfund sites, and a wide range of industrial clients.

SUEZ

Our next generation SimPACK regenerable ion exchange (IX) treatment system is a multi-bed design operated in a staggered mode process. Find out more and watch a video demonstration.

May we use cookies to track your activities? We take your privacy very seriously. Please see our privacy policy for details and any questions.

We pride ourselves in delivering superior ‘lifecycle performance’ by offering long-term, guaranteed, pay-for-performance contracts that produce the lowest total cost over the lifetime of an installation.

The ultimate in emergency response! A Free-Standing Stainless Steel Emergency Shower Certified by CSA to meet the ANSI Z358.1 standards.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Water system operations and maintenance services offered on an “as needed”, regularly scheduled, or continuous basis to keep your equipment running at peak efficiency

Sievers

Register to receive the Haws E-Newsletter, featuring Haws plumbing and safety product news, helpful articles and upcoming events.

Envirogen Technologies, Inc. is a leading international provider of environmental technology and process solutions that combine over 30 years experience in water and air treatment with process development and O&M expertise.

Veolia north america

High surface area granular activated carbon systems address a wide range of contaminants such as organics, chlorine, color, taste and odor.

Envirogen has provided effective, reliable solutions to a broad range of customers through all water stages in F&B plants.

Over 100 groundwater treatment systems in North America – handling a very broad range of contaminants and multi-contaminant sites.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Industrial customers benefit from Envirogen's technologies to improve product quality, reduce costs and meet environmental targets.

We help chemical manufacturing facilities reach processing, product recovery, cost reduction and environmental goals using our broad portfolio of solutions.

Envirogen's solutions address process and potable water, mining run-off waters, wastewater and groundwater treatment for a variety of mines.

Model 9201EFE AXION® Emergency Tempering Valve thermostatically mixes hot and cold water to provide a safe fluid supply for a single emergency eye/face wash, with a flow rate of 12 gpm (38.8 L).

Model 9201EFE (patent pending) is a thermostatic mixing valve that mixes hot and cold water to supply tempered water of up to 12 gpm (45.4 L) for emergency eyewash fixtures. Unit employs a paraffin filled thermostatic mixing element. Lowest internal pressure drop where supply pressure is low, and a high Cold Water Bypass flow rate of 10 gpm (37.8 L). The improved brass design with a one piece casting uses internal check stops, over-sized valve seats, a shuttle design that eliminates valve binding, and a funnel design to improve temperature control with better mixing at low flow rates. Lime and calcium resistant components are used throughout. The outlet temperature factory setting is 85° F (29° C). Maximum operating pressure: 125 psi (8.62 Bar). Temperature adjustment range 60 - 90° F (16 - 35° C). Min/max inlet hot water temperature: 120°/180° F (49°/82° C), with recommended inlet temperature: 140° F (60° C). Min/max inlet cold water temperature: 40°/70° (4.4°/21.1° C). Inlet 1/2" NPT(F). Outlet 3/4" NPT(F).

8615510865705

8615510865705

8615510865705

8615510865705