Backflow Preventers - Valves - reduced pressure backflow preventer

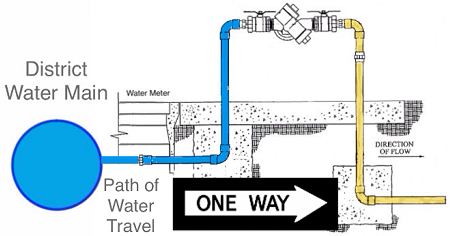

Backflow preventers are designed to stop the reverse flow of water in a plumbing system. Water suppliers often require their customers to install and maintain backflow prevention assemblies at each water meter to protect the supplier's distribution system from contamination and polution.The style most commonly required for this purpose is called a "Reduced Pressure Principal" (RPP) backflow preventer. Also known as "Reduced Pressure Zone" (RPZ), this type is preferred because it employs 3 elements of protection: the two spring loaded check valves prevent reversal of flow; the relief valve operates to discharge water prior to reversal of flow. Designed in this way, it can protect the distribution system from health hazards as well as mere polution, whether the flow reversal is due to backpressure or backsiphonage.

3/4 rpzbackflow preventer

A double check valve or double check assembly (DCA) is a backflow prevention device designed to protect water supplies from contamination.[1] It is different from the two-way check valves (sometimes erroneously referred to as double check valves) used in air brake systems on heavy trucks which select from the highest pressure source.

It consists of two check valves assembled in series.[2] This employs two operating principles: firstly one check valve will still act, even if the other is jammed wide open. Secondly the closure of one valve reduces the pressure differential across the other, allowing a more reliable seal and avoiding even minor leakage.

Reduced Pressure Backflow preventerTest Procedure

A dual check backflow preventer is similar to a double check valve in operation. It has two independent spring-loaded check valves. However, dual check valves usually do not include shutoff valves, may or may not be equipped with test cocks or ports, and is generally less reliable than a double check valve.[4]

RPZ meaning

The double check valve assembly is suitable for prevention of back pressure and back siphonage, but is not suitable for high hazard applications. It is commonly used on lawn irrigation, fire sprinkler[2] and combi-boiler systems.[3] If the hazard is higher, even a relatively low hazard such as using antifreeze in the fire sprinkler system, then a more reliable check valve such as a reduced pressure zone device may be mandated.

The Relief Valve is operating properly, but the #1 Check Valve is not, due to the debris or damage preventing the full closure of the Check. Depending on the amount of debris or damage, the Relief Valve can discharge just a slight drip or can open fully, flowing water until the shut-off valves are closed.

Debris has become lodged between the #2 check seat and sealing disc or the components are damaged. Some source of pressure increase in the water user's system (pump, elevation, heat, etc.) is overcoming the pressure delivered by the water supplier. Because of the debris or damage fouling the #2 check, the pressure in the Zone falls to the Relief Valve Opening Point. The Relief Valve will discharge until the supply pressure again exceeds the Zone pressure or the shut-off valves are closed.

When the end user opens a valve (faucet, sprinkler, etc), water flows in the normal direction from the supplier, downstream to fill the user's need. The flow of water pushes the spring-loaded check valves open. The tension of the #1 check spring maintainins the pressure difference in the Zone of Reduced Pressure. This difference in pressure keeps the relief valve in the closed position while water flows in the normal direction.

Difference between RPZ andbackflow preventer

Dark Blue = Supply-side pressure (for example, 100 psi) pushes against the #1 check and also fills the area on the "high pressure" side of the Relief Valve diaphram, pressing it closed.Light Blue = Reduced Pressure Zone - supply pressure pushes open the #1 check and is reduced by the #1 Check spring (for example, to 90 psi). This pressure difference across the #1 check valve maintains the relief valve in the closed position. If pressure in the Zone rises toward the supply pressure (within 2 to 3 psi), the Relief Valve discharges, preventing backflow (reverse movement of fluid).Grey = End-User Pressure - water pushes past the #2 check valve into the system of the end user. The #2 Check prevents backflow caused by pressure increases in the down stream plumbing.

RPZBackflow preventerdiagram

#1 = Number One Check Valve, spring-loaded up to 10 psi.#2 = Number Two Check Valve is loaded to less than 2 psi. RV = The Relief Valve operates by sensing the pressure difference across the #1 Check Valve. The Relief Valve must begin to open before the pressure difference falls below 2.0 psi.

The following diagrams are artist's renderings of a Wilkins Model 975XL2. It is shown in various conditions of operation to illustrate how the RPP backflow assembly offers protection against health hazards.

Small valves may be so compact as to be barely noticeable particularly when they are integrated into the bodies of existing taps (faucets). Larger check valves may be installed with ball valves at the ends, for isolation and testing. Often, test cocks (very small ball valves) are in place to attach test equipment for evaluating whether the double check assembly is still functional.

A reduction in supply side pressure caused by an incident such as a water main break, or a heavy water demand from activities such as fire fighting, causes the supply pressure to drop below the customer side pressure. A fouled #2 Check Valve allows the excess customer side pressure to act on the Relief Valve Diaphram, opening the Relief Valve discharge. Water will discharge until the supply side pressure again exceeds the customer side pressure and closes the Relief Valve or until the shut-off valves are closed.

The system has returned to a zero demand condition (no valves open downstream). However, debris between the #1 Check Valve seat and sealing disc, or damage in the components, is preventing the #1 Check from closing all the way. This allows pressure to equalize between the Supply Side and the Zone of Reduced Pressure. When this happens, the Relief Valve Spring pushes back against the Relief Valve Diaphram, opening the RV Discharge.

8615510865705

8615510865705

8615510865705

8615510865705