Bermad Australia - Water Control Solutions, Valves & Meters - water valves

Identifying a malfunctioning TPR valve is essential for maintaining the safety of your home. Here are some warning signs:

All safety valves, safety relief valves, boiler safety devices, controls, and electrical requirements shall be listed and labeled for their appropriate use ...

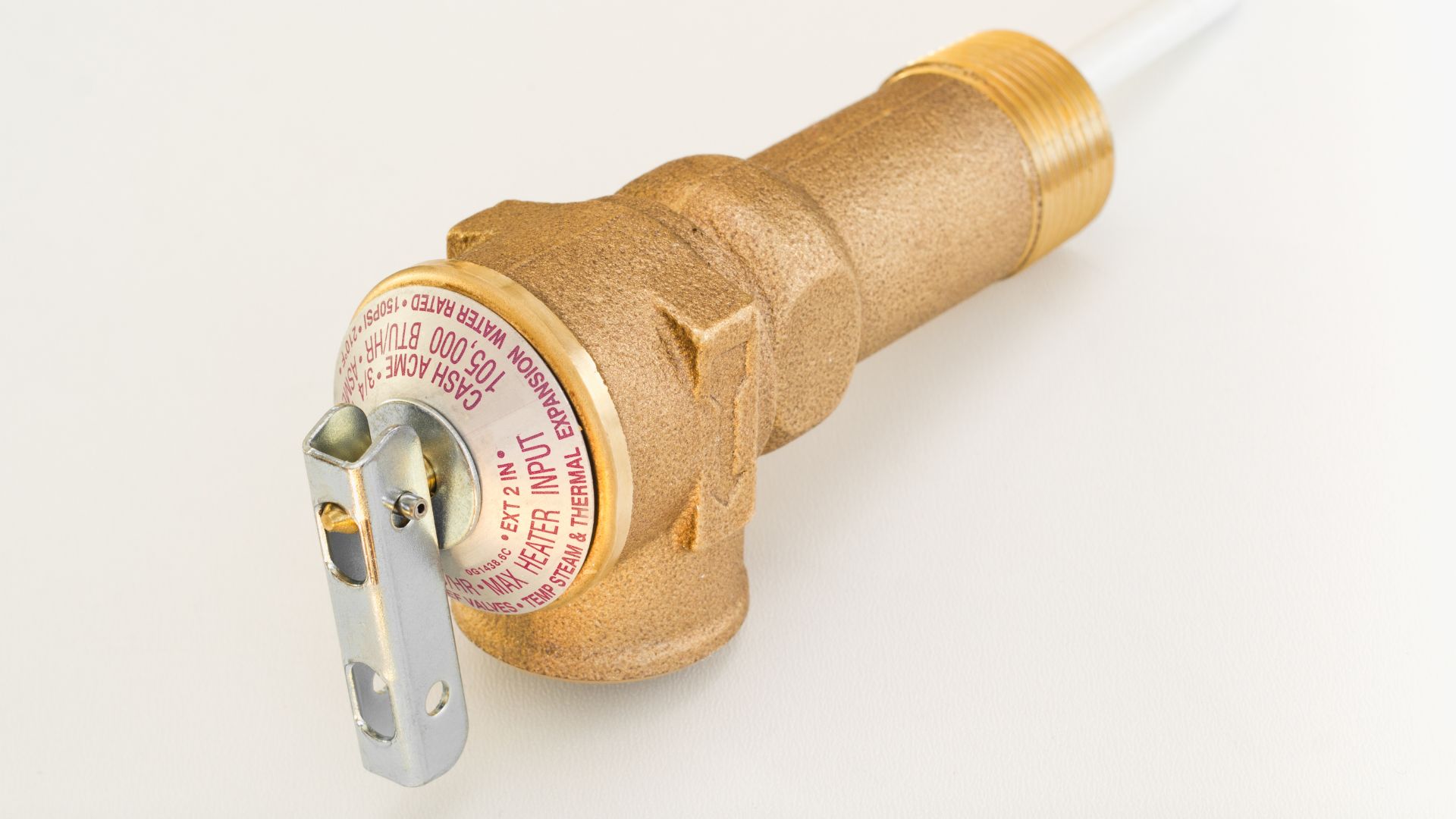

Designed specifically to prevent this risky scenario, TPR valves are pressure-sensitive switches that manually release excess heat and water vapour if predefined upper limits are exceeded.

For homeowners in the Gold Coast area, maintaining your TPR valve and hot water system need not be a hassle. The Gold Coast Plumbing Company specialises in ensuring your water heating systems are safe and efficient.

TPR valvedischarge pipe

This crucial function prevents damage to the water heater and protects your property and household from a catastrophic event. By manually venting the system when predefined maximum heat and pressure levels are exceeded, the TPR valve ensures your hot water service operates safely within regulated limits. The only thing standing between regular operation and explosion is its release of expanding steam and heat build-up before stability is compromised.

Even when maintaining your TPR valve, these safety components have a limited lifespan. As a rule of thumb, TPR valves should undergo replacement every 3-5 years to keep failure risks low. However, certain red flags can indicate a need for earlier substitution regardless of age.

Tpr valve- bunnings

With a basic grasp of TPR valve mechanics and some periodic preventative care, you can reliably release excess heat and pressure before they become a threat, saving you the cost and headache of emergency plumbing repairs.

To filter a substance, or to filter particles out of a substance, means to pass it through a device which removes the particles from it.

Tpr valvereplacement

Each Valve Control Group configuration in the stainless steel recessed box is available with either a thermostatic mixing valve or a tempering valve to make ...

In a hot water system, the TPR valve’s primary role is to release water if the temperature or pressure reaches unsafe levels. It is calibrated to activate when water temperature exceeds a specific point, generally around 99 degrees Celsius.

A critical yet often overlooked component of any hot water system is the Temperature Pressure Relief (TPR) valve. This safety feature prevents catastrophic overheating and dangerous overpressurisation within your hot water tank.

TPR valvewater heater

Popping, hissing, or rumbling noises can signal the valve operating under stress or a sediment build-up within the tanks.

TPR valveleaking

Routine visual inspections are also advised to check for visible signs of wear and tear or mineral build-up from hard water. Corrosion, debris, or scaling on the valve can impede its sensitive release mechanism. Catching these issues early allows for cleaning or replacement before function is impacted. For complete assurance, periodically enlist a certified plumber to professionally inspect the TPR valve, pipes, and full hot water system. They can detect any problems not apparent from exterior visual checks that may affect the valve’s safe operation.

Understanding the operation of a TPR valve helps in recognising its importance. The valve has two main elements: temperature and pressure sensors. When the internal temperature gets too high, the sensor expands and triggers the valve to open, releasing hot water and thus reducing the temperature and pressure inside the tank.

Incorrect handling can compromise the safety of your hot water system and may invalidate warranties. A professional plumber can ensure the valve is correctly installed and functioning, giving you peace of mind.

202167 — Should you install a hot water recirculation pump? Learn about the pros and cons along with the potential water and energy savings in this ...

A TPR valve is a safety device legally required in water heating systems to serve as a crucial fail-safe against dangerous buildups of interior pressure and heat.

2000SS DBL CHK VLV ASSY (AMES)

Tpr valvereplacement cost

This manual activation verifies that excess pressure can discharge and the valve’s release mechanism is in good working order.

Within the sealed environment of a hot water tank, regular heating cycles can generate expanding volumes of steam and intensifying thermal energy, elevating interior pressures to potentially catastrophic levels.

With the TPR valve adequately calibrated and maintained to Australian standards, you can rest easy knowing this inexpensive, unassuming safety component will automatically dissipate dangerous excess energy, preserving the integrity of your hot water system.

This inexpensive valve defends your water heater against unsafe pressure build-up. Replacing your TPR valve every few years assures that this crucial failsafe can be manually activated to protect your home when dangerously high temperatures occur.

Visible corrosion, mineral deposits, and bending of the release lever or discharge pipe can also warn that the valve may not properly relieve pressure when critical temperatures hit. Never ignore these telltale clues of TPR deterioration and past usefulness—continuing to rely on a faulty valve risks catastrophic system overpressurisation and failure consequences for health and home.

hot water pressure reliefvalve- bunnings

Proper maintenance is crucial to ensure your TPR valve can perform its critical safety function when needed. The valve should be regularly tested by lifting the lever every six months. When functioning correctly, water should flow freely from the valve and stop immediately after releasing the lever.

Immediately contact a plumber if, during testing, you ever observe the valve sticking open rather than closing tightly or any water leaks, even if slight, while in a closed position.

This comprehensive guide will provide homeowners with the working knowledge needed to understand what TPR valves do, why ongoing inspection and maintenance of this inexpensive but essential equipment is mission-critical, and how to ensure this small part operates smoothly for the safe, efficient function of your entire hot water system.

Choosing between deck-mounted and wall-mounted taps can impact both the look and functionality of your bathroom or kitchen. Dive into the benefits and drawbacks of each style to find out which tap type aligns with your design preferences and practical needs.

Combining recurring physical testing, visual checks, and full-system professional inspections provides a multi-layered maintenance approach to confirm that your TPR valve can reliably perform its hazardous pressure-relieving duties when needed.

Neglecting your pipes can lead to expensive plumbing disasters. Understand the factors impacting pipe lifespan, such as pipe material, water quality, and local climate. Determine the ideal maintenance frequency for your home. Safeguard your property with expert advice.

TPR valveinstallation

Backflow Preventers: RPZ · Filters: · Watts® LF009M3-QT RPZ Backflow Preventer, 3/4", 0391003. · Watts® LF009M2-QT RPZ Backflow Preventer, 2", 0391007. · Watts ...

Your kitchen mixer tap is a key element, both functionally and aesthetically. Discover our guide to selecting a mixer tap that complements your kitchen décor, whether it’s modern, traditional, or industrial.

Series 919 Reduced Pressure Zone Backflow Assemblies are designed to protect potable water supplies in accordance with national plumbing codes and water ...

With our experienced team, you can expect thorough inspections, expert maintenance, and quality replacements when necessary. Contact us today to schedule a service or learn more about how we can keep your hot water system in prime condition.

Upgrading to a smart water meter offers numerous benefits, including better tracking of your water usage, early leak detection, and cost savings on your bills. This guide explores the advantages of smart water meters, explaining how they can give you greater control over your home’s water consumption while promoting a more sustainable lifestyle

© 2024 Gold Coast Plumbing Company. All Rights Reserved. Elemental Resources Pty Ltd, trading as Gold Coast Plumbing Company. QBCC License No 15025411

The TPR valve is a small but significant component in your hot water system. Understanding its purpose, function, and maintenance requirements can prevent dangerous malfunctions and protect your household. Regular maintenance and prompt attention to any signs of trouble are the best ways to ensure the safety and longevity of your hot water system.

Proactively swap older valves that display functional or cosmetic issues for optimal safety. Even valves lacking outward problems should undergo preventative replacement within manufacturer-recommended timeframes.

Without a functioning TPR valve properly monitoring and releasing excess pressures, the consequences can be severe—explosions, leaks, floods, injuries, and system damage.

Similarly, when the pressure exceeds the set limit, the valve opens to allow water to escape, which decreases the pressure.

They are the components of your plumbing that enable hot water tanks to heat homes safely. By automatically venting any dangerous accumulating pressures before stability is compromised, TPR valves regulate your system within safe operating ranges, protecting against disastrous explosions and equipment failures while ensuring regulatory compliance.

Munich, November 11, 2000 The project German entrepreneur and engineer Franz Wieth of Germering near Munich has been known as a competitor in the FIA GT Championship. He usually shares the wheel of his Porsche GT2 with his son Niko. Some years ago, Franz Wieth who is a longtime Ferrarista and who owns a number of sports cars made in Maranello raced in the Ferrari 348 Challenge. Racing in the more sophisticated FIA GT Championship generated his interest in an adequate, purpose-made Ferrari of which there was none available. So, in late 1999 Franz Wieth and his team Wieth-Racing of Wessling near Munich started an ambitious project to develop a competitive GT-car based on a Ferrari 550 Maranello (s/n ZFFZR49B000112133). The result of about one year of hard work was presented to the public in Munich on November 11, 2000: The Ferrari 550 GTS. The 550 GTS Purpose-designed for racing in the FIA GT Championship, at Le Mans and in other endurance races, the 550 Maranello has been substantially altered: The car has received a new bodywork, replacing all body components except the roof by carbonfibre and Kevlar parts. The re-designed, aerodynamic body looks very aggressive, sporting large air-intakes in the huge frontspoiler and a giant adjustable rearwing which generates a remarkable downforce. A completely closed bottom section and diffusors to the front and to the rear are additional elements of the 550 GTS optimized aerodynamics. Needless to say that the standard interior has been replaced by a very Spartan racing interior featuring a very stable roll-cage and an additional protective tube structure to the drivers side. Weight has also been reduced by the use of perspex windows and the massive use of carbonfibre on the modified dashboard and center console. In total, the cars weight was reduced by almost 600 kg to about 1.100 kg which are almost perfectly balanced in a relation of 51:49. Unibal parts were used on the suspension, which is adjustable. The 550 GTS runs on huge OZ wheels in the dimension of 12 x 18 to the front and 13 x 18 to the rear, tires are Dunlop 280s to the front and 315s to the rear. Substantial changes to the engine include the enlargement to six liters (the 550 GTS now has a bore and stroke of 88 mm x 82 mm) and the fitting of a stainless steel sidepipe exhaust system. The 550 GTS produces about 600 hp and a maximum torque of 655 Nm, the maximum rev-rate is 7.000 min-1. Due to the FIA regulations, the engine had to be equipped with two large air-restrictors; without these restrictors, the power output of the 550 GTS would be even higher. The massive torque is handled by a sequential sixspeed gearbox attached to a Fichtel & Sachs MFX 200 racing clutch. The Brembo-made braking system features discbrakes with a diameter of 380 mm to the front and with a diameter of 350 mm to the rear. According to FIA regulations, the 550 GTS does not have an anti-lock system. The conversion of the car was performed by Baumgartner Sportwagen Technik (who did already prepare Franz Wieths Porsche GT2) and engine specialist Völkl of Tirschenreuth. The future Wieth-Racing have already found two sponsors: SL Llumar (car glass treatment) and CFC Car Film Components. Currently, one is still looking for a main sponsor whos name will become part of the teams name. Franz Wieth has also monitored the 550 Millennio project which was plagued by gearbox problems and up to now could not meet the expectations which had been set into this project earlier in 2000. Wieths 550 GTS differs in many aspects from the solutions used by Italtecnica on the 550 Millennio, and thus the German Ferrari promises to be more successful. In March of 2001, Wieth-Racing will perform their first test sessions on various circuits. If any other race-team or ambitious club-racer should be interested in the 550 GTS: It would be possible to order identical cars via Wieth-Racing, the price would be in the region of 600.000,-Euros. One more example (s/n 115802) has already been produced and is now (November 2000) undergoing final preparations; the roll-cage is being fitted at a specialist company in Paderborn/Germany. S/n 115802 will either be campaigned by Wieth-Racing as a customers car in 2001 or be offered for rent or leas during the season. More information at www.Wieth-Racing.de (in German, only)

A backflow prevention assembly test kit is a tool. A tool that when properly used, can diagnose how a backflow prevention assembly is operating.

Mechanical Joint Grooving Tool 2 In | AD2UZH | 3ULY5 | Australia & New Zealand Delivery | sales@raptorsupplies.com.au | +61 (08)81217761.

Lead-free reduced-pressure zone backflow preventers protect potable water supplies from harmful contamination. They install in applications that require ...

8615510865705

8615510865705

8615510865705

8615510865705