Caleffi 535651HA PressCal PRV ASSE 1003, 3/4" Press w - asse 1003

Water TechnologyAustralia

Water Technologyengineering

Different utilities use different treatment steps depending on the quality of the source water entering the treatment plant. Water from lakes, rivers, or reservoirs typically require more treatment than water from under the ground. This is because—compared to water from under the ground—lake, river, and reservoir water contain more:

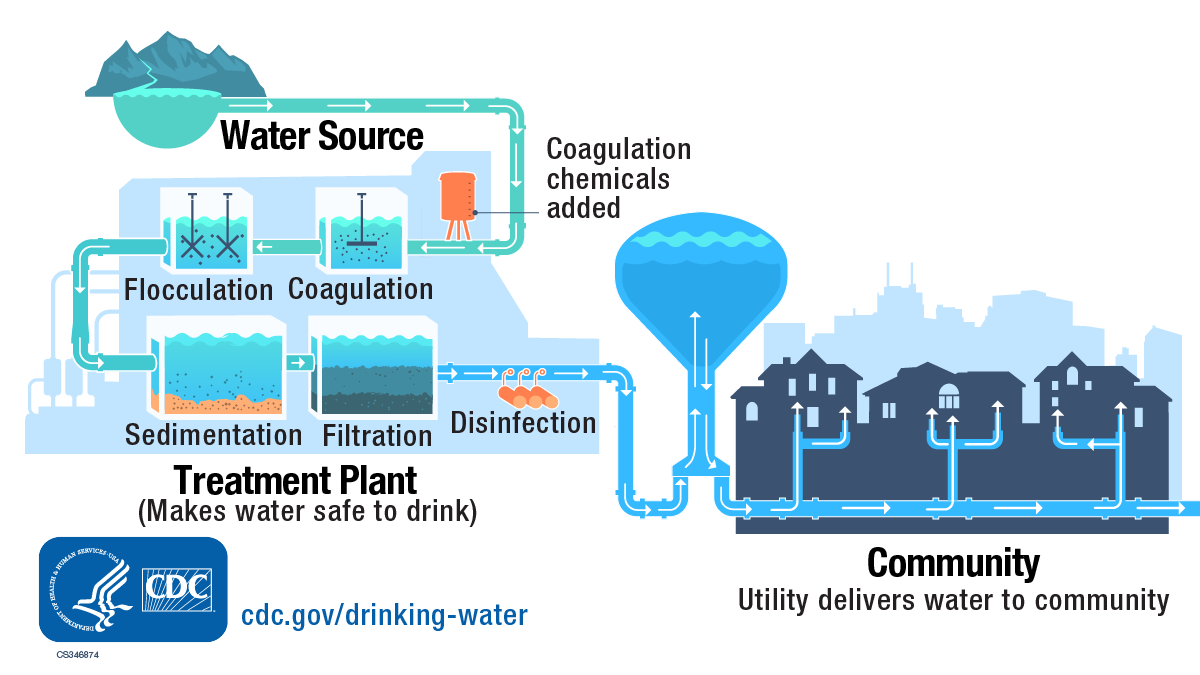

Water utilities often use a series of water treatment steps that include coagulation, flocculation, sedimentation, filtration, and disinfection.

Water TechnologyInc

The filters have different pore (hole) sizes and are made of materials such as sand, gravel, or charcoal. These filters remove germs, including parasites, bacteria, and viruses. They also remove dissolved particles, such as dust and chemicals. Activated carbon filters remove bad smells.

Water technologycompanies

Some water supplies contain specific chemicals or toxins that require utilities to use special treatment methods to control or remove them. These chemicals and toxins can include:

Water technologyexamples

Disinfection is often the last step. Water treatment plants may add one or more chemical disinfectants to kill any remaining germs. Common types of chemical disinfectants include chlorine, chloramine, or chlorine dioxide.

A lock ( ) or https:// means you've safely connected to the .gov website. Share sensitive information only on official, secure websites.

Water Technologyjob

Treatment plant staff make sure the water has low levels of the chemical disinfectant when it leaves the treatment plant. This remaining disinfectant kills germs living in the pipes between the water treatment plant and your tap.

Watertreatmenttechnology

Coagulation is often the first step in water treatment. Treatment plant staff add chemicals to the water that help bind together dirt and other small particles. The chemicals they commonly use include specific types of salts, aluminum, or iron.

Sedimentation separates out solids from the water. Flocs are heavier than water, so they settle to the bottom of the water during this step.

Water treatment plants can also use ultraviolet (UV) light or ozone to disinfect water. They may use UV light or ozone instead of, or in addition to, chemical disinfectants. UV light and ozone work well to disinfect water in the treatment plant. However, these methods do not continue killing germs as water travels through the pipes between the treatment plant and your tap.

Utilities that use a process called ultrafiltration put water through a filter with very small pores. This filter only lets through water and other small molecules (such as salts and tiny, charged molecules).

Reverse osmosis is another way to filter water that removes additional particles from water. Water treatment plants often use reverse osmosis when treating recycled water or salt water for drinking.

Flocculation is next. Flocculation is the gentle mixing of the water to form larger, heavier particles called flocs. Often, treatment plant staff will add additional chemicals during this step to help the flocs form.

Filtration is the next step. Once the flocs have settled to the bottom of the water, the clear water on top goes through several filters.

8615510865705

8615510865705

8615510865705

8615510865705