Careers at Evoqua Water Technologies - water technologies careers

Yeah, I think there’s value with every type of trap and every application. There’s value to every one of them being monitored because even the low pressure heating ones that are at 15 psi, they still have large orifice diameters. So when it does fail, it is letting a lot of steam through there.

Flush valves are another gray area when it pertains to water hammer arrestors, however again, you would be silly not to define them. Flush valves do not utilize solenoid valves to control the water flow, it is controlled by either a diaphragm or a piston, depending on the type of flush valve. Do these valves close quickly? The answer is “somewhat.” They do not close as rapidly as an electronic solenoid, but the relative circulation speed is much greater than for a lavatory faucet, and a significant water hammer can take place depending on the valve operation and the pressure. I have actually heard flush valves– particularly older designs– literally rattle the walls.

Some of them say up to three to five years, but we’ve heard and seen that it’s sooner than that. You might have to replace a battery once every year. Now you have a yearly maintenance task to take care of.

It can start to leak, the seat inside of the trap will start to fail and just discharge a little bit of steam through there. After a while that little bit of steam eats away the seat, and there’s more and more steam that’s lost. Sometimes it eventually goes into a blow through state where the trap is hardly reducing any of the steam pressure at all. That’s obviously very wasteful. Another way in which a steam trap can fail, and some people would say it’s more of a serious situation, is when the trap itself becomes plugged because the condensate builds inside the pipe instead of being released by the steam trap and creates a really dangerous situation called pipe hammer in worst case scenario, that can lead to a pipe explosion and people’s lives can be put in jeopardy.

I did over 20 years as a steamfitter, did a 5 years steamfitter apprenticeship and worked another 16 years as a journeyman. During that time, I worked on all sorts of Steam Systems, installing, demoing and servicing them. Working in all sorts of different environments, a lot of heavy industry. Also, I was a steamfitter apprenticeship instructor. My current position is within Everactive. I first started out as a Field Service Tech and then I went to Field Service Manager, having technicians underneath me. Now, I’m into education and training, and then also the subject matter expert for the steam straps and steam systems.

Water hammer arrestorfor washing machine

Some steam system operators haven’t done anything with steam traps in awhile, because they don’t realize there’s a problem. They think that maybe somebody did something 10 years ago, and they assume everything’s fine and dandy. Some steam operators do a steam trap audit on an every other year basis. They’ll send a person out into the field to take temperatures or ultrasound readings at each trap and take a note of that, but that’s only one to two minutes spent at each trap by a person over one or two years. Some steam operators are really more proactive with it, and they’re doing a steam trap audit, maybe on a quarterly or monthly basis, but if they do it monthly, one day a month, for a minute, they’re still missing quite a bit of time where the steep trap might be malfunctioning. There have been some other actual steam trap monitor companies, similar to us, and they use ultrasound or other methods to try to determine a failure. However, usually they read less often than Everactive’s solution because they’re working off of a battery, and they’re trying to maintain their battery health.

The ones with batteries take a lower frequency of samples because they’re trying to maintain their battery life. They might take a reading only every 15 minutes, or every hour, or possibly even longer than that. So, that could very well be missing a lot of intermittent blow through scenarios.

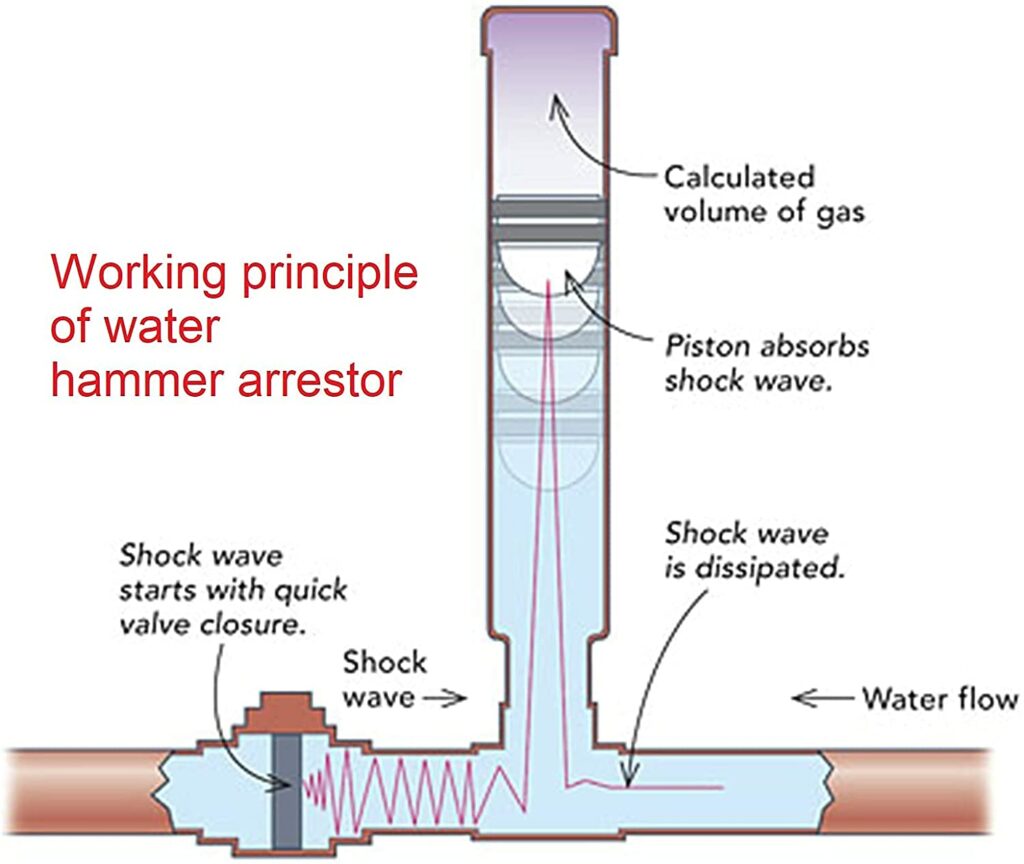

In this world of entropy, where whatever continuously gets more complex instead of less, water hammer arrestors are no exception. For the new engineers and designers who might be reading this post, water hammer arrestors are devices that soak up the pressure wave, or water hammer, that happens when a quick closing valve shuts and rapidly stops the circulation of water. The industry tests pressure transducers of the effect of water hammer, and it can easily spike for a little while to 500 psi just from the rapid closure of a kitchen or bathroom faucet with an average shut off. Paradoxically, a lever style area faucet is not a place where you would offer a water hammer arrestor due to the fact that it is not considered a quick closing valve, however that of course depends on how fast you close it.

Bestwater hammer arrestor

It probably always comes down to money. Do they have manpower or time, so if they’re doing it themselves with a person going out into the field, they have to make time for that person to do it. A lot of times, steam operators are just running on a skeleton crew or they just physically don’t have time for it. Another problem is money. If you need to come up with $100,000 to monitor steam traps, then you have to have a good justification to do that. Which, that’s what Everactive solution offers with the savings in fuel cost from replacing a steam trap as soon as it fails instead of every year or every month.

South End Plumbing specializes in all plumbing services, so remember, we are just a click away. We also specialize in video sewer line inspection – give us a call! South End Plumbing is one of the only companies that will give you a free estimate. Call us at 704-919-1722 or fill out the form online to schedule a visit.

The design of these do not require access to because they are upkeep complimentary unlike the air chambers of old ones. Recently some of the local plumbing inspectors are needing access. The UPC is a little gray on this subject considering that it referrals installation per the manufacturer’s recommendations, and the manufacturers normally state that they are upkeep free so gain access to is not needed.

Water hammer arrestortoilet

Yes. That’s what a lot of the audit companies offer, they’ll come in to audit it, then they’ll flag 10% of your traps as failed. Then, they’ll come back throughout the year, to replace the steam traps and they’ll schedule that with the steam operator to coordinate with shoutdowns.

Because you’re wasting energy, you’re heating up and creating excess steam and just discharging it into the atmosphere or into a return system, which is very wasteful.

Right, a big nice thing about the Everactive solution is that you’re removing the need for a person to go to the field and get into this awkward, hard to reach spot, 30 feet up in the air or down in a pit where it might create a need for a confined space entry permit. There are a lot of good reasons to monitor a steam trap, because we’re going to save a lot of time.

You’re going to lower all your costs, like the amount of make up water that you’re putting into your boiler system, the chemicals you’re putting in a boiler system. The dollar amount lost in gas that you’re using to heat up steam that’s getting wasted and reduced CO2 emissions as a result of that. There’s all sorts of different things that are bad if you’re not managing steam traps and constantly monitoring them.

Water hammer arrestordiagram

Industrialwater hammer Arrestor

The sizing and positioning of the devices are dictated quite particularly by the various manufacturers, so you have to refer to their literature to perform this task. The requirement (or lack thereof) for the devices is far less particular and often a subject of hot dispute.

2Water Hammer Arrestor

All steam traps are important! I guess you could say that steam traps for comfort heating, which is seasonal, aren’t as important because they’re only on for five or six months a year. It’s still wasting money, if it’s failing for five or six months of the year, and if you are not monitoring them you’re not going to know that. What if you’re doing your steam trap audit during the summer, when that portion of the piping is off? You’re never going to catch that.

We don’t normally see water hammer arrestors on coffee machines and fridge ice makers due to the fact that the circulation rate is small, the velocity is low, and traditionally they are never ever a problem. A washing maker has a much greater flow speed so the possibility of their necessity is much greater-or is it?. Washing machines are fed by rubber hose pipe connections between the unit and the wall supply. If these hoses are fairly versatile, chances are they will take in the potential water hammer prior to it goes back to the piping system. But since as the engineer you have no control over the kind of pipes utilized as the washer supply, you would be absurd not to set up water hammer arrestors. For the exact same factor, a garden hose does not produce water hammer even if it is closed rapidly with a spring release trigger.

How to installwater hammer arrestor

A steam trap is something that does exactly what the name suggests, it traps steam. There’s three main things that a steam trap is trying to do.

Because of the failures that we talked about, open failure is wasting steam, a closed failure is creating potential hazards. It’s not just necessarily a hazard to a person or equipment, it’s a hazard to the whole process overall. It might shut down a process where a customer could potentially lose a million dollars in a day if it’s shut down.

It can back up and flash within the system and it can create a violent reaction within the system. It’s like a miniature explosion within the system. Sometimes if it’s a large enough pipe and backed up enough, it can create a really violent explosion where it can cause damage to a facility or even worse, it could hurt a person.

Basically, like I said before, if you’re running on a maintenance crew that’s a skeleton crew. They don’t have time to do that, then it might make sense for them to hire it out.

There are disk traps or thermodynamic traps. A lot of times the wear in a disk trap happens at the little disc itself internally, where sometimes that’ll get a little groove in there because the steam itself will actually eat into the disk. There are float traps that have a ball float in it, kind of like a toilet tank.The float that senses the level of the condensate and it opens a valve up once it gets to a certain level. Then, it also has a thermostatic trap, which reacts to the temperature itself. So, once it senses that it’s at 212 degrees Fahrenheit or above, it’ll close and below that it’ll open up to remove condensate and air. And there are inverted bucket traps, which are probably one of the best types of all around traps. Inverted bucket traps work by opening and closing a valve connected to a cylinder that resembles an upside-down bucket. As steam collects in the bucket, it causes the bucket to float higher and higher on the condensate collecting below it. When the bucket rises high enough, it opens the valve and the condensate drains away. Float and thermostatic and inverted buckets are the most popular traps out there.

It should be put into the maintenance program, a work order should be created by the steam operator. It should be taken care of as soon as possible. Sometimes production won’t allow that to happen, they have to wait until production comes down. It could be a week or a month before they can get to it, but getting to it within a month is a lot better than waiting till the next year.

Years ago water hammer arrestors were consisted of air chambers that were a capped piece of pipe installed vertically and filled with air. The air offers the cushion to take in that water hammer. Because air is soluble in water, with time these air chambers would end up being flooded since all the air would be absorbed into the water. Once flooded, the air chamber is no longer an air chamber however a water chamber and will no longer absorb the pressure from water hammer. (Remember, water is incompressible.).

To me, it’s a no brainer to have everything constantly monitored. I’m not just saying that because I work for Everactive, it just makes sense. If you’re going to only look at something once a year for one minute, versus every minute, all year long, it just makes total sense. Then you’ll know how your facilities are operating, and make sure you are not wasting money, production time or generating more CO2 emissions than you need.

The general guideline in NC is that water hammer arrestors are required on all fast closing valves. Solenoid valves, the electronic snap-action valves that manage water flow to sensing unit faucets, dishwashers, washing makers, ice makers and coffee machines, are all fast closing valves requiring water hammer arrestors– or do they? The code states water hammer arrestor shall not be required on any valves where plastic pipe is used for water distribution piping, indicates that they are not required for PVC and PEX.

Water hammer arrestorLowe's

We connected this month with Todd Klanderud to bring into the spotlight an often forgotten but critical part in a steam system. In this Q&A Todd shares his knowledge on critical questions for steam operators interested in operating their system at peak efficiency to eliminate wasted energy and reduce CO2 emissions.

Due to this anomaly, old fashioned air chambers required a drain and gain access to such that they could be drained pipes of water and filled with air regularly in order to operate as meant. This of course was upkeep intensive.

In the mid 70s water hammer arrestors started manufacture as a stainless-steel bellows inside a steel outer housing. This gadget, produced by Zurn, Smith, Mifab and others, functioned as a shock arrester that was maintenance totally free, because it utilized the expansion and contraction of the bellows to absorb the shock and did not rely on an air/water user interface. Some years later on, another gadget was developed by PPP, Sioux Chief and others that used a piston inside a copper pipe chamber that moves up and down in response to pressure variations, and like the bellows, is upkeep totally free.

There are main distribution lines in a steam system after the boiler, and they’ll have drip legs to remove condensate that might have built up in the steam line every so many feet. In some distribution lines the steam traps are placed every 300 feet as well as at changes in elevations, in other distribution lines they are placed every 500 feet, in some cases they are placed as often as every 100 feet throughout the whole distribution lines. From there the steam goes to a pressure reducing station and it might drop down from 150 psi to 60 psi and drip lines will also be installed there to remove more condensate as it goes through the pressure reducing station and as it comes out of the pressure reducing station as well. Then, finally the steam goes to whatever application it’s intended for. It might be a tank where we’re trying to heat up some product, and there’ll be a trap at each end of the heating coil or whatever process it’s going to. So, all throughout the system, there are steam traps.

Sometimes it’s the older people out in the field that are used to doing it manually. They’ve always done something a certain way for 30 years and it’s something new, so they’re really going to be skeptical of it.

Well, just along the same vein, they’re a game changer because you can get so much data compared to manually doing it and you do not need to replace the batteries. If you are replacing the batteries you are just replacing one maintenance task with another and it is not sustainable over time. It’s kind of stone age technology, the old way of doing it versus Everactive’s way.

It can either be a lot of them, you can replace the internals of them so you don’t have to physically remove the trap itself, you just open up the trap and change out the internal guts of it. You can also just physically remove the trap itself and replace it with a brand new one. If you replace the trap you then have the option to rebuilt it and reuse it next time there is a similar trap that fails. Rebuilt will save you maintenance dollars and also reduce the replacement time and downtime of the operations.

8615510865705

8615510865705

8615510865705

8615510865705