febco 765 1 1/2 - 2" check assembly repair kit - febco 765-1 repair kit

The set temperature should balance safety to prevent scalding (typically around 40°C or 105°F) and effectiveness in controlling bacteria while adhering to any specific building or health and safety regulations.

This placement minimises the dead leg of mixed water, reducing the risk of bacterial growth and ensuring quick response to temperature changes.

In conclusion, understanding the differences and appropriate applications of mixing valves, tempering valves, and TMVs is essential for any plumbing engineer.

Robust backflow prevention valves to protect plumbing systems from contamination, back pressure or back siphonage.

In the aftermath of the August 16, 1933 outbreak, it was clear that immediate action was needed to ensure that such a tragedy would never happen again. Chief amongst developments was the creation of the Foundation for Cross Connection Control and Hydraulic Research, which today is a division of the University of Southern California. Over the years, the professionals who have passed through the Foundation have gone on to revolutionize the challenging field of backflow prevention, renowned for their dedication and insights in the water safety industry. In fact, many plumbing professionals consider these backflow prevention pioneers to be the Green Berets of the Plumbing Industry–testing, installing, and maintaining systems in the harshest conditions and with no blueprint, save for their own ingenuity. Without backflow prevention and backflow test kits, people would routinely face the risk of consuming water with toxins, chemicals, waste, and countless other contaminants.

201147 — Pauls, North Carolina location of Mueller Steam Specialty, formerly known as Core Industries, including workers whose unemployment Insurance (UI) ...

Ideally, mixing valves should be installed close to the point of use to minimise the length of mixed water in the pipes, reducing bacterial growth risk and ensuring rapid temperature response.

This high temperature effectively inhibits the bacteria, reducing the risk of Legionnaires’ disease. However, such high temperatures pose a scalding risk to users.

202253 — A hose bib is essentially a faucet on the outside of your home that taps into the main water line.

3/8mixing valve

CASE STUDIES Greengate, UK "I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software. The ability to output the design straight into Revit assisted clash detection and coordination." Read the full case study

TMVs are typically used in more demanding environments, like healthcare facilities, where maintaining a constant temperature is crucial.

This valve is particularly useful in preventing extreme temperature variations, making it an ideal choice for environments requiring precise temperature control.

A TMV uses a thermostatic element to sense the outlet temperature and adjusts the mix automatically, providing an additional layer of safety.

They are mandated in various building codes, especially in settings where there is a risk of scalding, such as in hospitals, schools, and elderly care facilities.

Book a demo or start a free trial with h2x today to discover how we can help you improve your design and calculation workflow!

On August 16, 2021, Mid-West Instrument and thousands of other companies in the backflow prevention industry will celebrate National Backflow Prevention Day by acknowledging new technologies and backflow accessories, attending backflow prevention webinars, and interacting online with manufacturers. Contact us today to learn more about backflow prevention and how you can make an impact.

"The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop."

It is no more challenging to repair a water pressure-reducing valve than fixing the kitchen faucet. How do I adjust my pressures? With the right tools and ...

The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance."

Mixing valvewater heater

The software automates flow rate, velocity, pressure, pump duty, plant size, and recirculation system calculations, freeing you from tedious math.

Inside the valve, a control element, such as a diaphragm or a thermostatic element, responds to the incoming water’s temperature and pressure.

Mixing Valvefor sink

Yes, most mixing valves allow for post-installation temperature adjustments to suit user preferences or comply with updated safety standards.

Explore a wide range of our 825y Febco selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy ...

Understanding these valves, which are essential components in modern plumbing systems, is crucial for ensuring safety, efficiency, and compliance with regulatory standards.

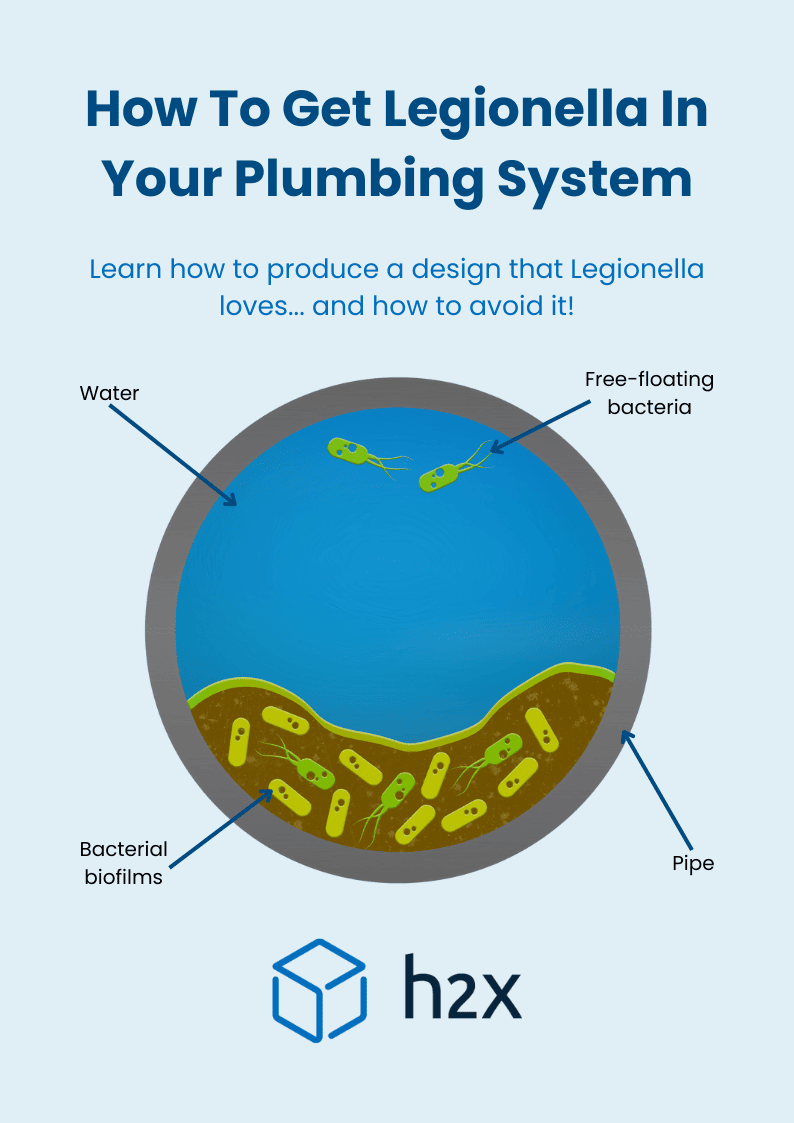

Yes, by allowing water to be stored and circulated at high temperatures, inhibiting Legionella growth, and then reducing it to a safe temperature, mixing valves indirectly help reduce the risk of Legionnaires’ disease.

A high quality industrial valve suitable for inlet pressures up to 2500KPa. They are designed to regulate outlet pressures between 100 and 600 KPa.

4 Apr 2019 — the number for 12,322 BTU is ( 58 Drill size ) So the size of hole to drill into the orifice spud will be 59 for 11,742 BTU I would try this ...

CASE STUDIES Salon Republic, USA "The quality of the designs saw significant improvement with the adoption of h2x." "The software offers precision through detailed result outputs and advanced options for efficient pipe sizing, allowing heating engineers to optimise based on parameters like maximum velocity and pressure drop." Read the full case study

3/4mixing valve

CASE STUDIES Award-Winning Heating Design "Using h2x was pivotal, allowing for precise heat loss calculations, pipe sizing and flow rates for each room. This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort. The strategic placement of heat pumps and careful sizing of pipework were crucial in maintaining minimal pressure drops over an 18-metre distance." Read the full case study

Thermostaticmixing valve

August 16, 2021, is National Backflow Prevention Day, which commemorates one of the world’s first backflow-related tragedies and recognizes the countless advancements made in backflow prevention technology since then. Over the ensuing decades, these advancements have improved the daily lives and overall health of billions of people worldwide.

Two of the key hotels used in this endeavor had cross‐connections between rooftop water towers, with one connection being clean and the other dirty. The intermixing of the two led to a badly contaminated water supply and an influx of germs that spawned dozens and dozens of severe cases of amoebic dysentery. Because the disease’s incubation period is 12 – 30 days, detection didn’t happen right away and in one place. Instead, the problem went undiagnosed until nearly 100 people had died and another 700 had fallen ill over a span of 206 cities in the U.S., with an additional 1,000 additional cases in the city of Chicago alone. Each and every case was traced back to the water supply of the two hotels.

They blend hot and cold water to a safe temperature and maintain this temperature even when the incoming water temperatures fluctuate.

The valve dynamically compensates for changes in water pressure and temperature, maintaining a stable and comfortable water temperature for the user, regardless of variations in the plumbing system.

MasterMixing Valve

A TMV includes a thermostatic element that automatically adjusts the mix of water in response to temperature changes, maintaining a stable output and providing a fail-safe against scalding.

Mixing valves blend hot and cold water to deliver it at a safe and consistent temperature, helping prevent scalding while ensuring comfort.

In many regions, building codes mandate the installation of mixing valves in certain settings, such as residential homes and healthcare facilities, for safety reasons.

Warning: Cancer and Reproductive Harm – www.P65Warnings.ca.gov For complete information on Proposition 65, please read this informational PDF or visit www.p65warnings.ca.gov

Mixing valvefor boiler

"I would estimate over the length of this project, I have spent 50% less time designing than I would on our previous software.

This ensures the water at the point of use is at a comfortable and safe temperature, balancing the need for Legionella control with the prevention of scalding.

Shop our Watts Pressure Reducing Valve collection. Zoro has low prices & fast shipping on millions of tools, parts and supplies for your business.

To resolve this, mixing valves are used to reduce this hot water to a safer, warm temperature by blending it with cold water.

If the cold water supply to a TMV fails, the valve will shut off the flow of hot water as a fail-safe measure to prevent scalding.

These valves provide a mechanical constriction in the pipe, much as an orifice plate reduces the cross-sectional flow area, thereby effecting a local pressure ...

WaterMixing Valve

It’s a specialised type of valve designed to precisely control water temperature, ensuring safety and comfort in plumbing systems.

Water in plumbing systems is heated to high temperatures, often above 60°C (140°F), primarily to control the growth of Legionella bacteria, which thrive in warm but not hot environments.

The maintenance frequency depends on water quality and usage and typically includes regular checks for scale buildup and operational testing.

The user-friendly interface by h2x aids engineers in creating top-notch designs and improving productivity, ensuring compliance with industry standards.

National Backflow Prevention Day is a collaborative effort led by Watts Water Technologies, Inc., which for more than a century has been a world leader in water-related technologies and solutions. The purpose of National Backflow Prevention Day is four-fold: to acknowledge the importance of backflow prevention, to help educate the public about the importance and usages of this life‐saving technology, and to recognize the water-quality professionals responsible who design, install, and maintain backflow preventers on a global scale. Fourthly, this special day remembers the victims of one of the world’s most tragic backflow incidents.

Step into the realm of plumbing valves and find out everything you need to know about mixing valves, which includes uncovering the distinctions between tempering valves and thermostatic mixing valves (TMVs).

TMVs also have a fail-safe mechanism that shuts off the water flow if the cold water supply fails, preventing dangerously hot water from being delivered.

This mechanism ensures a consistent output temperature, safeguarding against sudden fluctuations that could lead to scalding.

Clemco sandblaster parts - Clemco 100024 - ACV Air Control Valve w/belt.

This level of detail ensured that the heating load accurately matched each space's requirements, minimising energy waste and maximising comfort.

In this blog, we’ll explore the requirements and intricacies of mixing valves, including the differences between tempering valves and thermostatic mixing valves (TMVs).

The August 16, 1933 event was one of the first documented backflow incidents, and one of the deadliest. In 1933, not long before the Chicago World’s Fair was scheduled to open, city planners put profit over health by abandoning quality plumbing practices and instead focusing on the creation of housing for as many fair-goers as possible. In the face of this reckless expansion, Chicago’s water mains and sewage system proved grossly undersized, poorly designed, and rich with unhealthy impurities for which there was no contingency plan.

8615510865705

8615510865705

8615510865705

8615510865705