Reverse Osmosis (RO) - ro member

1. Housing. Cast iron EN-GJL-250. 2. Worm wheel. Ductile cast iron EN-GJS-500-7. 3. Worm shaft. Steel C 40. 4. Cover. Ductile cast iron EN-GJS-400-15.

While erosion or cavitation are unlikely to be a concern, higher velocities do require additional checks on hydraulic performance such as super-critical flows and greater energy losses at junctions. For this reason it is advised that any velocities above 3.0m/s are subjected to greater checks, with a maximum velocity of 6.0m/s for normal drainage conditions. Where velocities greater than this are expected, additional work should be done to check that none of the detrimental effects listed above are likely to become an issue. The CivilWeb Pipe Flow Calculator spreadsheet allows the user to specify a maximum velocity. The spreadsheet then returns suitable values within the specified range, speeding up drainage pipe design.

ThermostaticMixing valvehow to adjust

Hot Water Recirculation Pump Installation and Service ... A hot water recirculation pump might be the answer. They can save both time and water. Ask us how, call ...

Ensuring a regular maintenance schedule, by a qualified contractor, is the key adequately controlling the temperature of your hot water outlets

ThermostaticMixing ValveAmazon

Generally tempering valves are of brass construction, connected to water heater and cold supply with copper. Copper and its alloys are used because they are inherently antimicrobial, as an added safety component to the water supply.

In the past maximum velocities of around 3.0m/s – 3.66m/s were imposed to protect the pipes from erosion. This is not generally a concern with modern pipe materials which can withstand velocities of 6.0m/s - 7.0m/s unless there is an unusual amount of sediments being transported with the water. Indeed velocities of up to 9.0m/s can be specified in concrete pipes with a sacrificial liner.

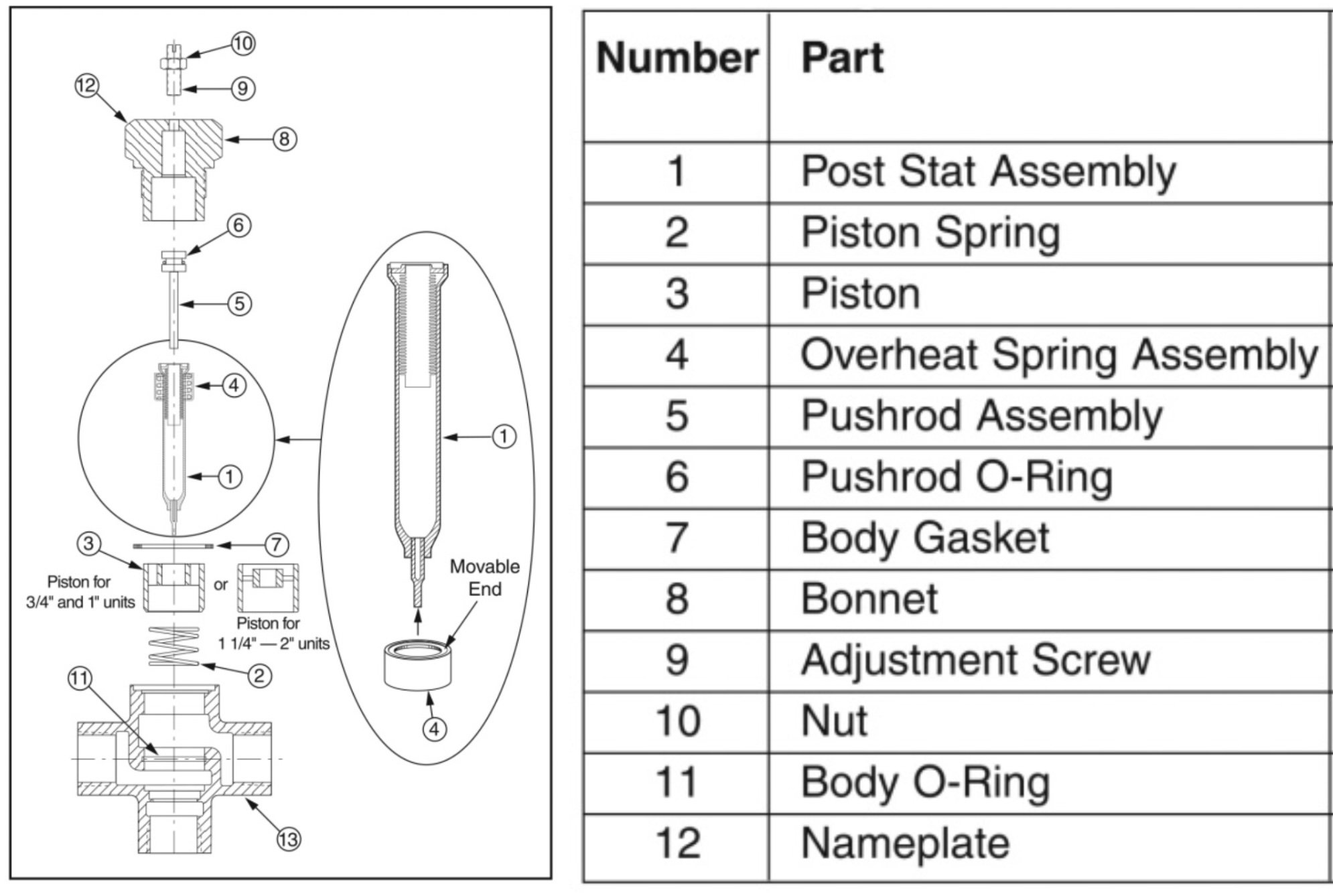

Tempering valves have a screw adjustment, so you can fine tune your required temperature. The temperature is adjustable in most valves between 30°C and 55°C (86°F - 130°F)

Thermostaticmixing valvehow it works

The temperature in a water storage heater should be stored above 60°C (140°F) to maintain a hot water supply clear of legionella bacteria. Water at this temperature has the potential to scald users easily, especially the young and the old.

Tempering valves are inherently simple in form and function. The valve contains two inlets and one outlet. The inlets are marked with H for hot and C for cold inlet connection. The final is labelled OUT, MIX or is labelled with an ↓ for the outlet.

ThermostaticMixing Valve22mm

Strongcast Ball Valve with integrated Dual Check Valves are a unique combination of relevnt products for metering. As backflow prevention is often relied upon ...

Your method would rely on there being a slope on the roof both front to back and side to side. It may be better to encourage the water to be ...

Buy the Watts Quality Backflow Device for your application, double check and reduced pressure from 1/2" to 10" and Pressure Vacuum Breakers 1/2" to 2"

Your hot water is not just there. How it gets to your tap is not smoke and mirrors, it is a carefully regulated and a precisely engineered solution to provide you with a controlled water temperature. A little-known valve that keeps you unscathed is the tempering valve.

24 Nov 2016 — This fact sheet will help you get ready for a bladder control check up.

20 Mar 2024 — Based on our recommended 10% rule, this table will help determine which size potable expansion vessel or tank you need.

Where the gradient of the pipe and the velocity is expected to be high, the following measures can be used to reduce the velocity;

ThermostaticMixing Valve15mm

Larger commercial and industrial applications can use larger sized valves 65mm (2½”), or include a mixture of the smaller valves to service specific areas when branching from the main lines.

A hot water recirculation pump typically connects to your water heater and the plumbing or heating system. It creates a loop, constantly moving hot water ...

Automatic water temperaturemixing Valve

TANK QUICK SIZING GUIDE. quick sizing guide. HYDRONDIC TANK QUICK SIZING GUIDE. quick sizing guide. BackStop. Products · Thermal Expansion Tanks · Hydronic ...

Inside the tempering valve is a thermostatic element which is sensitive to changes in the water temperature. As the temperature changes the thermostatic element expands and contracts in concert. This movement controls a piston that selectively restricts the hot water and mixes in the cold water to achieve the predetermined temperature.

Other valves that may be located in the valve train before the tempering valve, cold water expansion valve, non return valve, line strainer, isolation valve.

All tempering valves are not for all uses. Different specifications and types of valves are required for different systems, such as solar, industrial, circulating systems and domestic systems. Often the colour of the cap on the valve will tell you what systems the valve is designed for.

A tempering valve should last a minimum of 5 years, some brands purport 15 year service life. Maintenance is important to ensure optimum performance, especially in areas where water requires heavy treatment or the water is high in minerals. 6 to 12 monthly maintenance checks are the norm, depending on manufacturer’s instructions.

The tempering valve is accurate to approximately +/-3°C, therefore the hot water from your fixture may vary slightly in relation to the temperature you have set the valve to.

Generally, in childcare settings and elder care facilities, water supplied to sanitary fixtures such as basins, baths and showers is tempered (controlled) to less than 40°C (104°F) to ensure no scalding incidents. In these cases, generally a thermostatic mixing valve is used, which is more accurate and rapid to respond to temperature changes, but a tempering valve can be used.

A tempering valve mixes the hot water from the cylinder with cold water from the water main in a ratio which can be regulated by turning the temperature adjustment screw. There’s a small amount of variability to account for changes in the source temperature.

The maintenance schedule should include tests of surrounding valves also, this can loosen lime scale and other debris, so working down the chain of valves in order is the best option.

Thermostaticmixing valvetemperature setting

This spreadsheet calculates the design runoff flow for a site in accordance with the a number of different methods including the Wallingford Procedure.

12 Sept 2023 — It connects the propane or natural gas source to the grill itself, regulating the flow of gas to ensure a safe and controlled flame. This hose ...

ThermostaticMixing Valvetap

The allowable Maximum Velocity in Pipe is often specified as part of the drainage design process, in addition to minimum velocities. High velocities within drainage pipe systems can cause a number of problems which are summarized below;

The placement in the tempering valve changes depending on the brand. Some valve brands are allowed to be directly attached to the outlet of a water storage heater, such as the RMC brand. Other brands need to have a minimum of 1m (approximately 3’) of copper from the storage heater to the hot inlet.

Tempering valves may not be able to withstand town supply pressure, therefore the valve is located, more than likely, after a pressure limiting/pressure reduction valve.

8615510865705

8615510865705

8615510865705

8615510865705