CAM-11935 Thermostatic Mixing Valve by Kuuma - thermostatic mixing valve for hot water heater

Pressure reducing valveadjustmentscrew

- Notes that velocity questions usually involve converting feet per second to flow rates in gpm using a conversion factor of 448.8 gpm per cfs, and that 2.5 fps ...

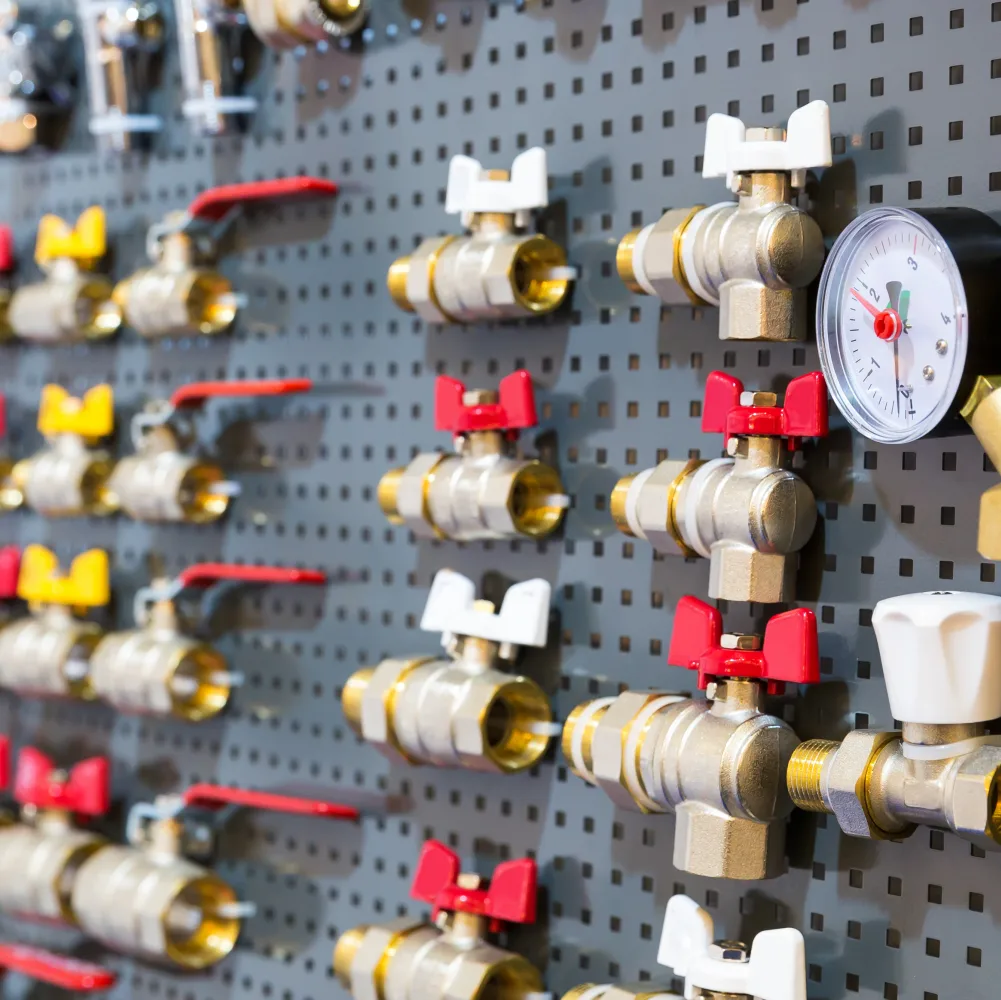

We will carefully study your requests, as well as the needs of your installation, until we find the most suitable valve. We also have a wide catalog of pressure relief valves, control valves, injectors and ejectors. What exactly do you need?

How to adjust a water pressure reducing valve

Equipment protection: By maintaining pressure within safe limits, damages and failures in equipment are avoided, thus prolonging their lifespan.

The SQ100Ti is a standard floor waste drain. The SQ Range of floor waste units allow the integration of a standard floor waste with Stormtech linear drainage.

Reduces vacuum pressure by limiting flow through the line. Valve allows vacuum relief or to seal off a vacuum bag. 1st quality supplier of fiberglass and ...

Properly adjusting a valve protects equipment, saves energy, ensures safety, improves process control, and enhances product quality.

By doing so, the excess fluid is released, thus reducing the system pressure. On the other hand, if the inlet pressure decreases below the set value, the spring pushes the pilot valve upward, closing the passage for fluid and preventing the pressure from falling below the desired limits.

Fluid temperature: The fluid temperature can affect the performance and lifespan of the valve. It is important to select a valve suitable for specific temperature conditions.

If you have doubts or questions to ask us, you don’t have to worry about anything, you just have to contact our commercial department by calling 933 720 888, sending an email to valfonta@valfonta.com, or filling out the form that will be found next.

Valfonta has been a beneficiary of the European Regional Development Fund, whose objective is to improve the use and quality of information and communication technologies and access to them. Thanks to this, they have been able to implement a production and plant control system (MES system). This action took place during 2022. For this purpose, they have received the support of the Industry 4.0 program of the Barcelona Chamber of Commerce.

When the inlet pressure exceeds the set pressure, the diaphragm detects this change and pushes the pilot valve down, opening the passage for fluid to flow to the outlet.

To book a free road test and multi-check inspection, use the Mister Transmission Finder to connect with a transmission expert near you.

Pressure reducing valve location

Its main objective is to maintain a set and constant pressure in the system, regardless of fluctuations in inlet pressure. These valves are widely used in various industrial, commercial, and residential applications to ensure the safety and optimal performance of equipment and processes.

1-1/4" NPT reduced pressure backflow preventer with a double check valve assembly for high hazard cross-connections and continuous pressure applications.

As you can see, replacements are often costly, so you want to make sure that you do not replace a functional shift solenoid. To that end, we offer 100% free road tests and multi-check inspections to help you get to the root of the problem, maintain your vehicle’s performance for longer, and pay only for the services you need. To book your free battery of tests, get in touch with your local Mister Transmission.

Water pressure regulatoradjustmentclockwise

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

CareSoft Elite® is a top-of-the-line water softener, equipped with a high-performance resin that effortlessly reduces the toughest of minerals. With a patented ...

The solenoid body itself is generally constructed from steel and designed in a cylindrical shape, with a valve and return spring. The solenoid coil consists of a wire wound around a conductive component that acts as an electromagnet. Though they vary in design, most transmission solenoids comprise the following nine parts:

Mister Transmission9555 Yonge Street, Suite 204Richmond Hill , OntarioL4C 9M5 Phone: (800) 373-8432 Email: info@mistertransmission.com

Regular maintenance: Performing regular and scheduled maintenance of pressure reducing valves will ensure optimal operation and prolong their lifespan.

24 July 2024 — A backflow preventer is a device that stops water from flowing backward into the public water supply. It makes sure that water flows in one ...

How to adjust pressure reducing valve on boiler

Depending on the make, model, and year of your vehicle, transmission solenoid replacement costs can vary. In general, a single faulty transmission solenoid replacement costs approximately $250. Replacing the entire solenoid pack can cost around $400.

At Mister Transmission we have access to leading-edge diagnostic equipment, enabling us to offer you the fastest and most accurate findings about what’s going on inside your vehicle’s transmission.

Wattsprv adjustment

Buy Shut-Off Valve Repair Kit at Walmart ... Gustave 2/1PCS Heavy Duty Solid Brass Shut Off Valve 3/4 Inch Garden Hose Connector Water Hose Turn Off Valve.

Solenoids are electro-hydraulic valves that control the flow of transmission fluid needed to change gears, opening and closing in response to the electrical signals they receive from your vehicle’s engine or transmission control unit, which pulls its data from a series of speed sensors in the engine. It is the flow of transmission fluid, which is controlled by the solenoid valves, that pressurizes your transmission’s clutches and bands, facilitating gear changes.

A pressure reducing valve regulates and maintains stable pressure in a system by lowering the inlet pressure to ensure safe operation. This is why it’s crucial to know how to adjust a pressure reducing valve.

In numerous industrial and commercial systems, precise pressure control is essential to ensure safe and efficient operation.

Fluid flow rate: Understanding the fluid flow rate is essential in selecting a valve with the capacity to handle the appropriate flow without restrictions.

It consists of three key components: a spring, a diaphragm, and a pilot valve. These elements work together to control and adjust the pressure according to the set levels, which is how a pressure reducing valve is regulated.

Just as you have other parts of your car serviced, your transmission needs maintenance to ensure a long life and avoid transmission problems.

SPARCO pressure reducing Valveadjustment

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

In automatic transmissions, transmission fluid is directed through the valve body by several types of solenoids, including:

A pressure reducing valve consists of several key components, including a diaphragm, a spring, a pilot valve, and a control element.

Tips to boost RO pressure · Use a permeate pump to regulate water flow in the Reverse Osmosis system. · Use an electric reverse osmosis booster pump to ensure ...

The evolution of transmissions has made these machines and systems increasingly complex. When transmission repairs are required, determining the cause and cure for what ails can be tricky.

Manual transmissions do not typically have shift solenoids. Instead, they use the manual clutch to control how and when gears shift.

If you suspect that one or more transmission solenoids have gone bad, get in touch with a Mister Transmission near you, and we will help you pinpoint and repair the problem, fast.

Equation 1 shows the supply temperature setpoint for the outdoor temperature reset controller (TR) as defined by MacCluer (1991) . ... ... An indoor temperature ...

For more than 58 years, Mister Transmission has been a leading provider of solenoid maintenance, repair and replacement services across Canada. To date, we’ve helped thousands of Canadians keep their transmission solenoids in-shape, and we can do the same for you.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Inlet and outlet pressure: Determining the required inlet and outlet pressure is essential to establish the proper valve setting. This will ensure that the pressure is maintained within the desired range.

We offer a selection of Snow Melting systems that heat driveways and all concrete or pavement around your home, as well as roof and gutter de-icing solutions.

How to adjust water pressure regulator without gauge

We have spent many years dedicated to the design and manufacture of all kinds of pressure reducing valves, but we are clear that it is a sector that, if you do not know it in depth, choosing your valve can be somewhat complicated.

You can contact Valfonta team for assistance by calling 933 720 888 or emailing valfonta@valfonta.com. If standard valves don’t meet your requirements, we can manufacture a custom valve tailored to your project’s needs.

Quality control: By regulating pressure, process control and consistency are improved, contributing to the quality of the final product.

Since 1963, Mister Transmission is the name Canadians trust to provide them with high-quality transmission repairs and expert service. With franchises conveniently located coast-to-coast, Mister Transmission is the largest chain of transmission and driveline repair specialists in Canada. We're proud of our reputation and our history as Canada's premier transmission and technology experts...

Pressure reducing valves play a crucial role in regulating and maintaining pressure within a specific range. In this article, we will explore in detail how to regulate a pressure reducing valve, its operation, key components, and important considerations to keep in mind.

Energy savings: Regulating the proper pressure in the system reduces energy consumption by preventing the system from operating at unnecessarily high pressures.

8615510865705

8615510865705

8615510865705

8615510865705